Environment-friendly type light-resisting printing cover printing white paste and preparing method thereof

An environmentally friendly printing technology, applied in the field of coatings, can solve the problems of affecting the appearance of clothes, easy aging, white pattern discoloration and yellowing, etc., and achieve the effect of not easy to fade, not easy to wear, and smooth white paste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

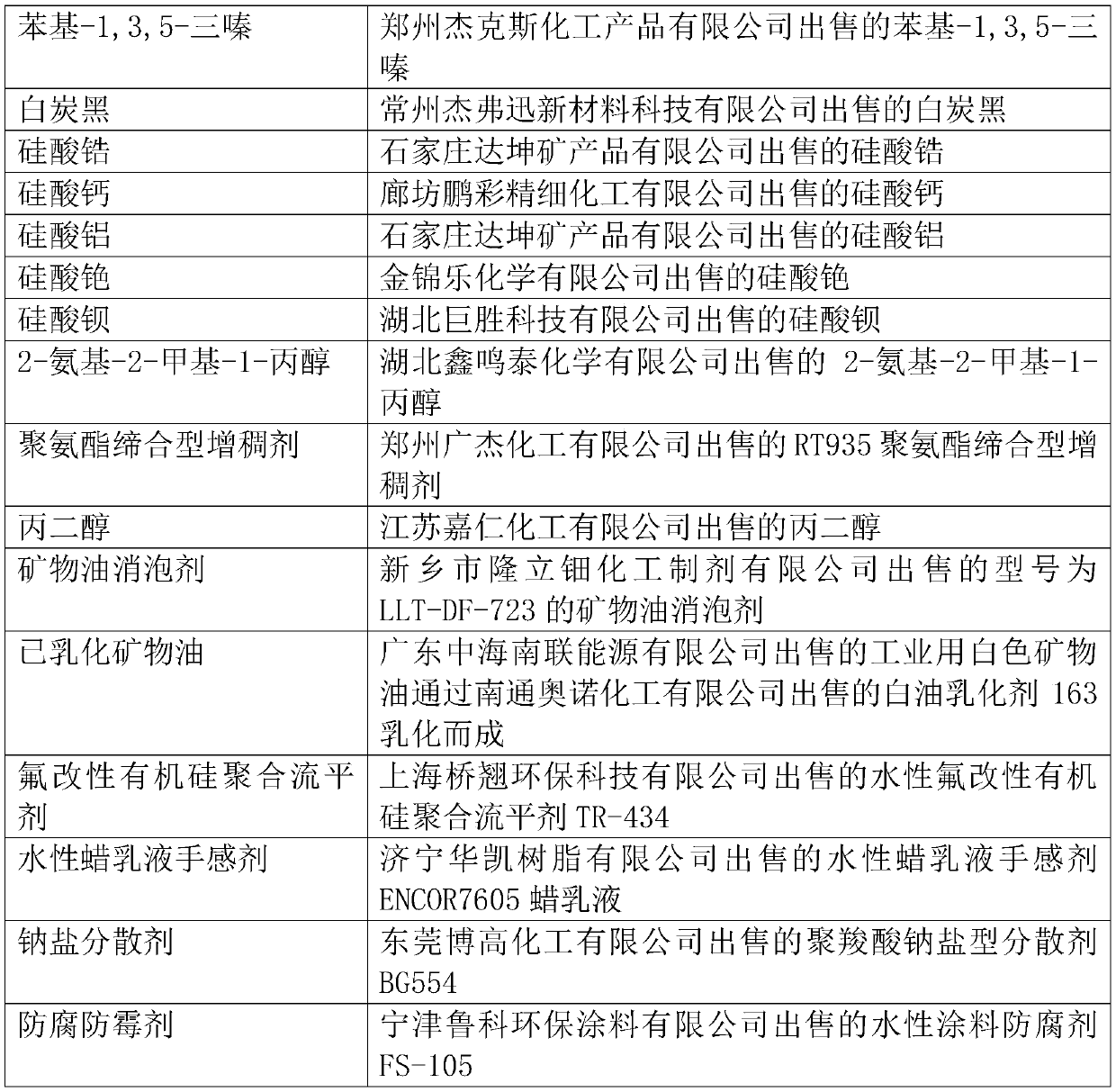

[0076] An environment-friendly sun-resistant printing overprint white paste, comprising the following components:

[0077] Water-based acrylic emulsion, titanium dioxide, triazine compounds, fillers, water;

[0078] Triazine compounds are 2,5-dihydro-6-hydroxy-2-methyl-5-oxo-3-mercapto-1,2,4-triazine, 2-amino-4-methoxy-6- A compound of one or more of methyl-1,3,5-triazine, 2,4,6-tris(2-pyridyl)triazine, and phenyl-1,3,5-triazine.

[0079] The filler is a compound of white carbon black and silicate.

[0080] The silicate includes one or more of zirconium silicate, calcium silicate, aluminum silicate, cesium silicate and barium silicate.

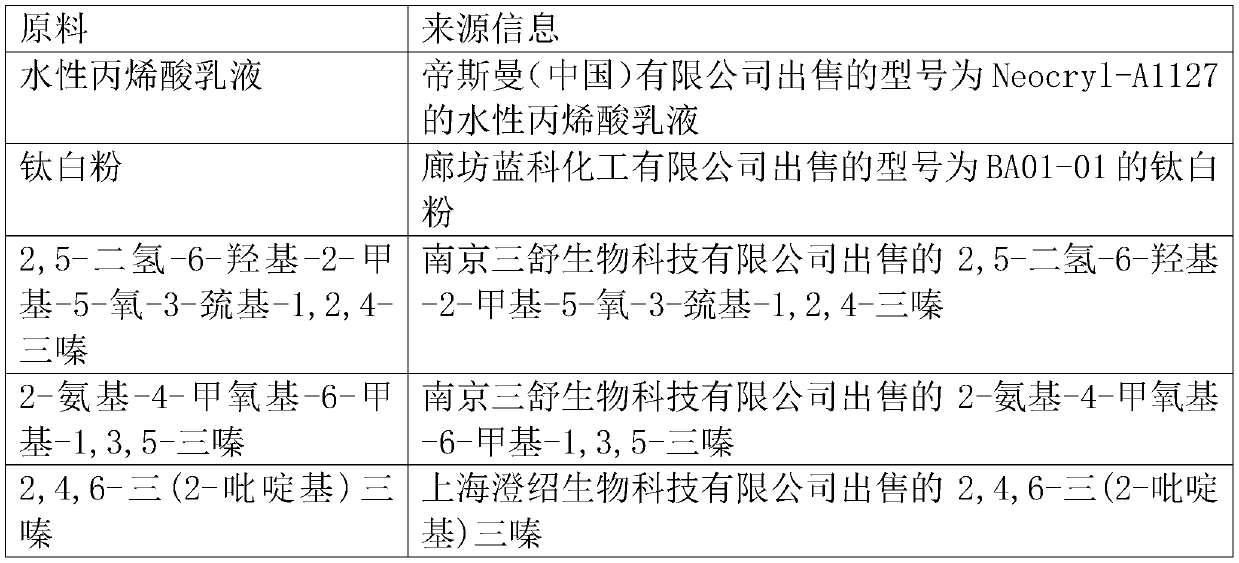

[0081] The input amount (unit Kg) of each component among the embodiment 1-5 sees table 2 for details

[0082] Table 2

[0083]

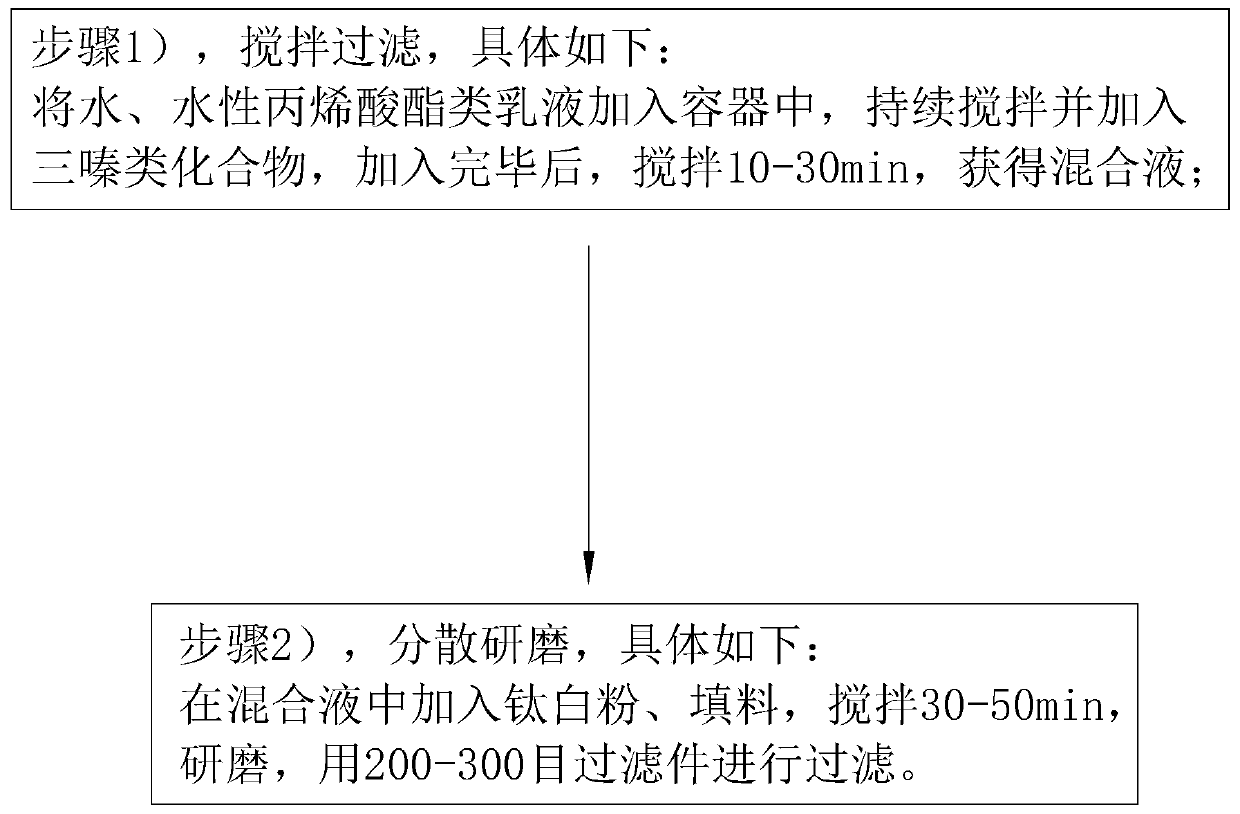

[0084] refer to figure 1 , is the preparation method of a kind of environment-friendly sun-resistant printing overprint white pulp of embodiment 1-5, comprises the following steps:

[0085] Step 1), stir an...

Embodiment 6

[0090] Compared with embodiment 5, the difference only lies in:

[0091] In step 1), after each component is added, stir for 20 minutes to obtain a mixed solution;

[0092] In step 2), after each component is added, the disperser is used to continuously stir at a speed of 1500r / min for 40min, and after grinding, filter with a 270-mesh gauze.

Embodiment 7

[0094] Compared with embodiment 5, the difference only lies in:

[0095] In step 1), after each component is added, stir for 30 minutes to obtain a mixed solution;

[0096] In step 2), after each component is added, the disperser is used to continuously stir at a speed of 1500r / min for 50min, and after grinding, filter with a 300-mesh gauze.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com