A chemical mechanical polishing solution and its application

A chemical-mechanical, polishing liquid technology, applied in polishing compositions containing abrasives, electrical components, circuits, etc., can solve the problem of lack of polishing rate selectivity, etc., and achieve the effect of good removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The advantages of the present invention are further described below through specific examples, but the protection scope of the present invention is not limited to the following examples.

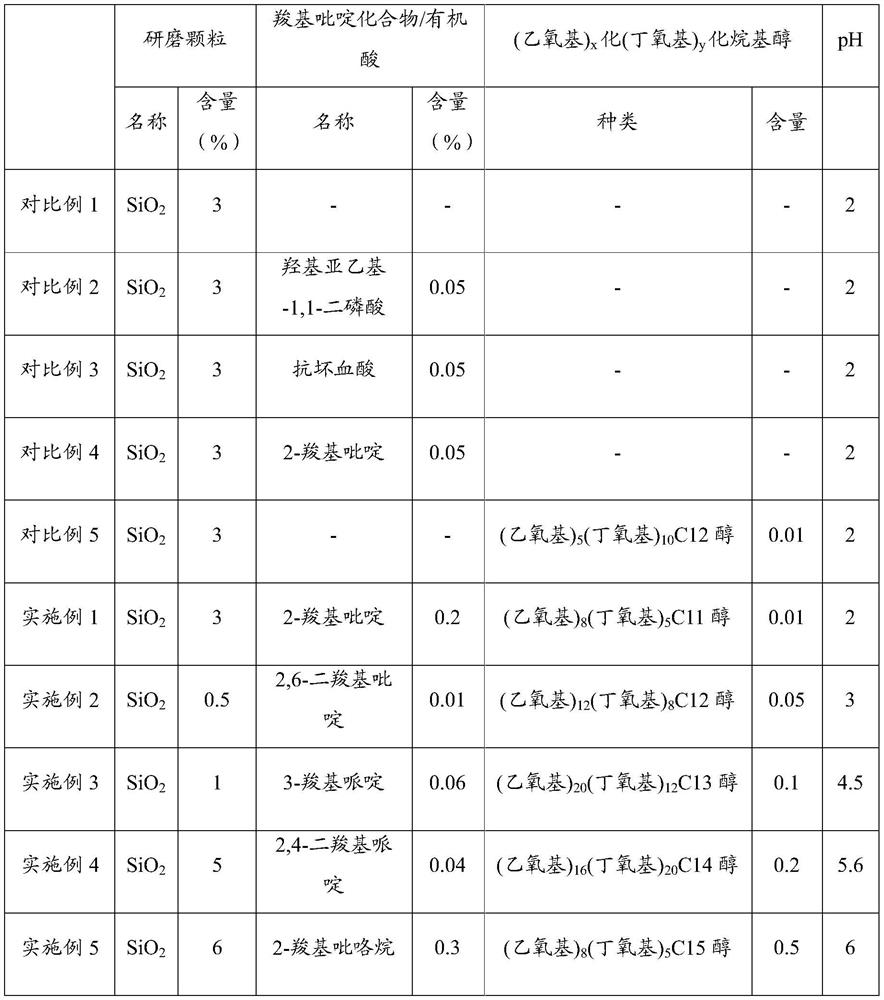

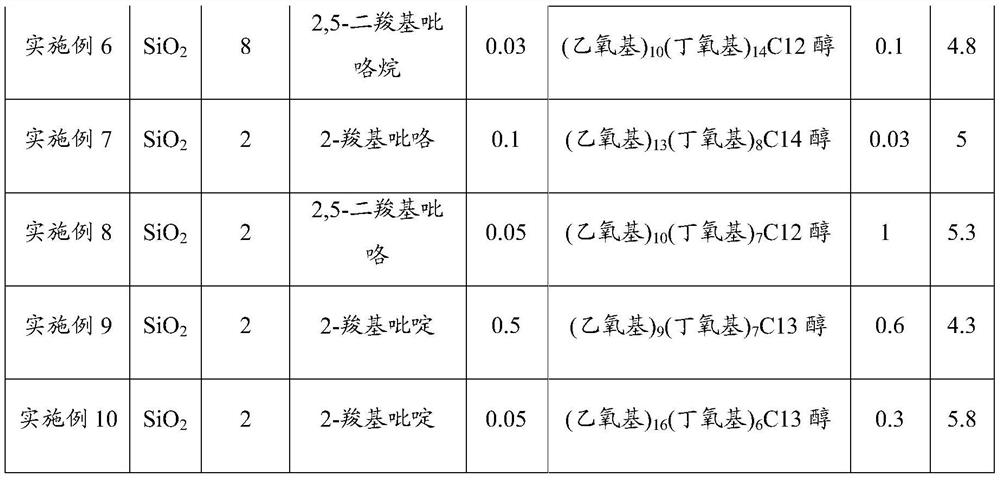

[0020] Table 1 shows the composition and content of the polishing liquids of Examples 1-10 and Comparative Examples 1-5 of the present invention. According to this table, the polishing liquids of the examples and comparative examples were prepared, the components were mixed uniformly, the mass percentage was made up to 100% with water, and the pH was adjusted to the corresponding value with a pH regulator to obtain the polishing liquids of the embodiments and comparative examples of the present invention.

[0021] Table 1 Compositions of polishing liquids of Examples 1-10 of the present invention and Comparative Examples 1-5

[0022]

[0023]

[0024] 8-inch polycrystalline silicon wafers containing silicon nitride and silicon dioxide were polished with the chemical mechanical p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com