Force-induced responsive polymer with light-operated switch function

A light-controlled switch and polymer technology, applied in the field of force-responsive polymers, can solve problems such as difficulty in reuse, difficulty in intelligent response and regulation function, and weak regulation ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0284] In the preparation process of mechanoresponsive polymer foam materials, mechanical foaming method, physical foaming method and chemical foaming method are mainly used to foam the mechanoresponsive polymer.

[0285] Wherein, the mechanical foaming method is to introduce a large amount of air or other gases into the emulsion, suspension or solution of the polymer by means of strong stirring during the preparation of the mechano-responsive polymer to make it a uniform foam, It is then shaped into a foam by physical or chemical changes. In order to shorten the molding cycle, air can be introduced and emulsifiers or surfactants can be added.

[0286] Wherein, the physical foaming method is to use physical principles to realize the foaming of the polymer during the preparation of the mechanoresponsive polymer, which includes but not limited to the following methods: (1) inert gas foaming method, That is, under pressure, the inert gas is pressed into the molten polymer or pas...

Embodiment 1

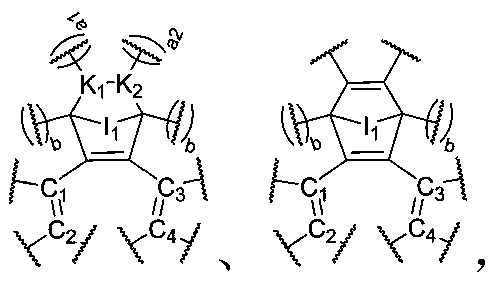

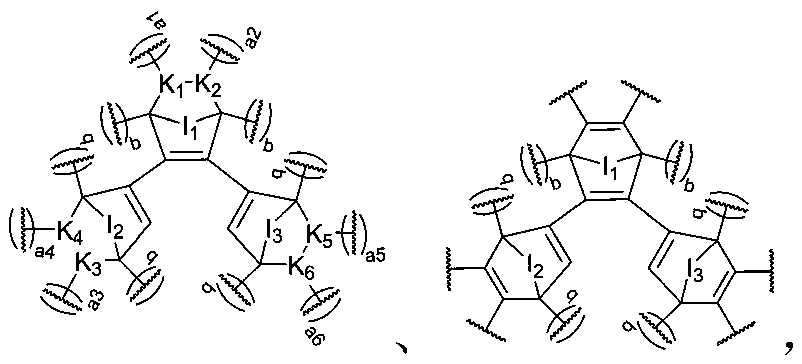

[0302]

[0303] Weigh 1.8g of compound (a) and dissolve it in 10ml of toluene solvent, add 0.96g of N-(2-hydroxyethyl)maleimide, stir and react at 90°C for 24h, wash with ethyl acetate and deionized water Compound (b) was obtained after purification.

[0304] Add a certain amount of toluene solvent into a dry and clean reaction bottle, seal it, use argon gas to deoxygenate for 1 hour, add 0.2 mol of compound (b) and 0.2 mol of polyethylene glycol 400 into it and stir to dissolve, then add 2 ml of three Ethylamine was mixed evenly, and 0.4 mol of suberoyl chloride was added dropwise to continue stirring and mixing for 4 hours. After the reaction is finished, the polyester-based polymer is purified by drying under reduced pressure to remove the solvent. Dissolve a small amount of polymer in toluene and prepare a 10 mg / ml solution. Different mechanical response properties can be obtained by ultrasound under UV locking and visible light unlocking; under the irradiation of visi...

Embodiment 2

[0306]

[0307] Using compound (a) and N-(2-hydroxyethyl)maleimide as raw materials, they were dissolved in toluene solvent, heated to 80° C. and stirred for 24 hours to prepare dihydroxy compound (b).

[0308] Add a certain amount of toluene solvent into a dry and clean reaction bottle, seal it, use argon gas to deoxygenate for 1 hour, add 0.2mol of dihydroxy compound (b) and 0.2mol of polycaprolactone glycol into it, stir and dissolve , add 2ml of triethylamine and mix evenly, dropwise add 0.4mol of terephthaloyl dichloride and continue to stir and mix for 4 hours. After the reaction, remove the solvent by drying under reduced pressure to obtain a polyester product. Dissolve a small amount of polymer in toluene and make a solution of 10 mg / ml. Different mechanoresponsive properties can be obtained by ultrasound under UV locking and visible light unlocking; under visible light irradiation, the polymer undergoes a reverse DA reaction, followed by The polymer can be recovere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com