Covalent bond type alkali-free accelerator and preparation method thereof

A technology of covalent bond and accelerator, which is applied in the field of covalent bond type non-alkali accelerator and its preparation, and can solve the problems of short service life of non-alkali accelerator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation of covalent bond type non-alkali quick-setting agent comprises the following steps:

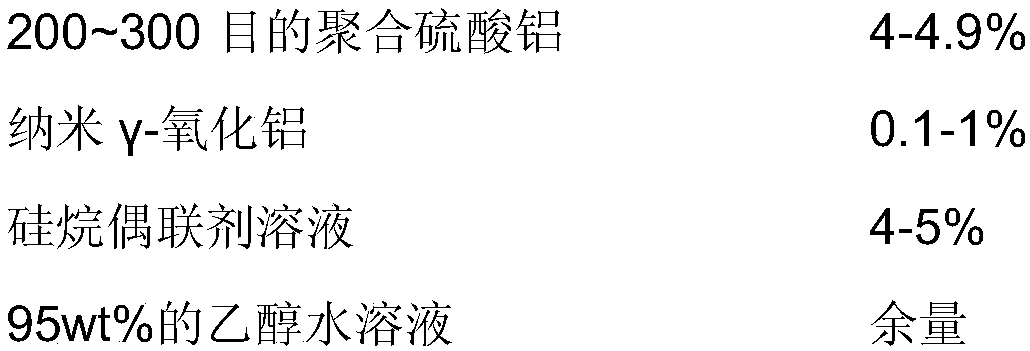

[0029] (1) Add 4g of 200-300 mesh polyaluminum sulfate and 1g of nanometer γ-alumina to 90g of 95wt% ethanol aqueous solution, and then ultrasonically disperse for 1h to obtain a uniformly dispersed suspension; then add 5g of 1wt% completely hydrolyzed γ-methacryloxypropyltrimethoxysilane ethanol solution; under the protection of nitrogen, stirred and reacted at 80°C for 24h, then centrifuged, washed with ethanol for 3 times, and finally dried in vacuum at 60°C to obtain the inorganic compound Point A.

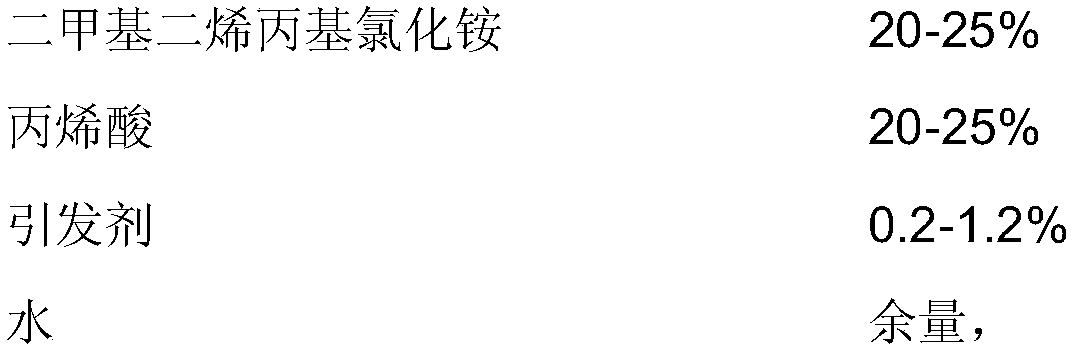

[0030] (2) Mix 20 g of dimethyl diallyl ammonium chloride, 25 g of acrylic acid and 54.8 g of water uniformly, then add 0.2 g of ammonium persulfate and mix uniformly to obtain organic component B.

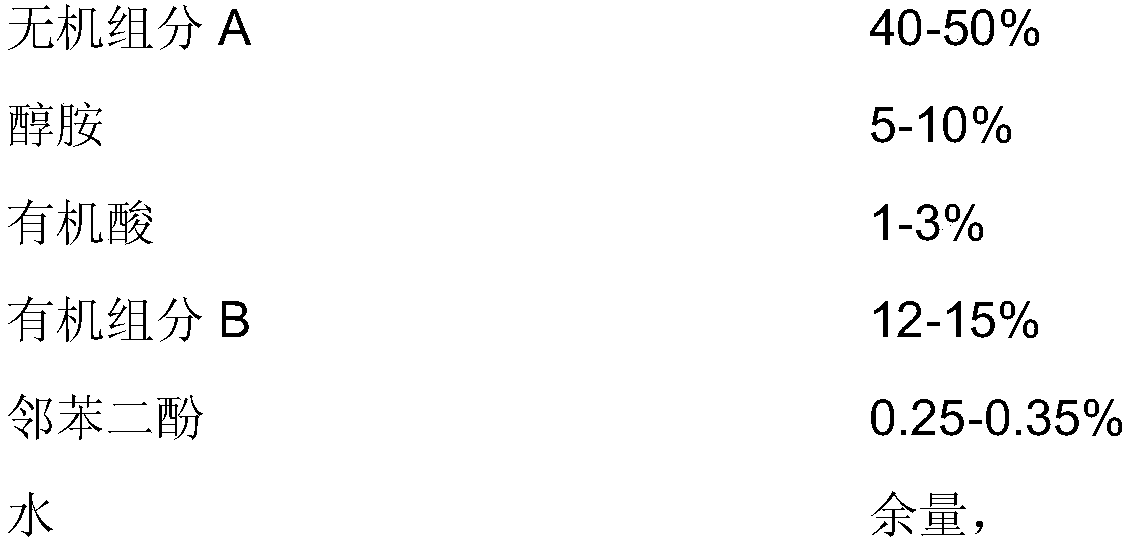

[0031] (3) Mix 40g of inorganic component A, 5g of diethanolamine, 3g of oxalic acid and 39.75g of water evenly, heat to 60°C, then add 12g of organic component B and 0.25...

Embodiment 2

[0033] The preparation of covalent bond type non-alkali quick-setting agent comprises the following steps:

[0034] (1) Add 4.9g of 200-300mesh polyaluminum sulfate and 0.1g of nanometer γ-alumina to 91g of 95wt% ethanol aqueous solution, and then ultrasonically disperse for 1 hour to obtain a uniformly dispersed suspension; then add 4g of 3wt% completely Hydrolyzed γ-methacryloxypropyltrimethoxysilane ethanol solution; under the protection of nitrogen, stirred and reacted at 80°C for 24h, then centrifuged, washed with ethanol for 3 times, and finally dried in vacuum at 60°C to obtain Unit A.

[0035] (2) Mix 25g dimethyl diallyl ammonium chloride, 20g acrylic acid and 53.8g water uniformly, then add 1.2g sodium persulfate and mix uniformly to obtain organic component B.

[0036] (3) Mix 50g of inorganic component A, 10g of triethanolamine, 1g of lactic acid and 23.65g of water evenly, heat to 80°C, then add 15g of organic component B and 0.35g of catechol respectively, keep ...

Embodiment 3

[0038] The preparation of covalent bond type non-alkali quick-setting agent comprises the following steps:

[0039] (1) Add 4g of 200-300 mesh polyaluminum sulfate and 1g of nanometer γ-alumina to 90.5g of 95wt% ethanol aqueous solution, and then ultrasonically disperse for 1 hour to obtain a uniformly dispersed suspension; then add 4.5g of 2wt% completely Hydrolyzed γ-methacryloxypropyltrimethoxysilane ethanol solution; under the protection of nitrogen, stirred and reacted at 80°C for 24h, then centrifuged, washed with ethanol for 3 times, and finally dried in vacuum at 60°C to obtain Unit A.

[0040] (2) Mix 22g of dimethyl diallyl ammonium chloride, 23g of acrylic acid and 54g of water uniformly, then add 1g of potassium persulfate and mix uniformly to obtain organic component B.

[0041] (3) Mix 50g of inorganic component A, 10g of triethanolamine, 1g of lactic acid and 23.65g of water evenly, heat to 80°C, then add 15g of organic component B and 0.35g of catechol respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com