a short circuit transition co 2 Apparatus and method for welding synchronous pulsed magnetic field control

A technology of short-circuit transition and magnetic field generating device, which is applied in the direction of manufacturing tools, welding equipment, arc welding equipment, etc., which can solve the problems of increased spatter, reduced spatter, and inability to ensure synchronization, etc., and achieves the effect of reducing hindrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

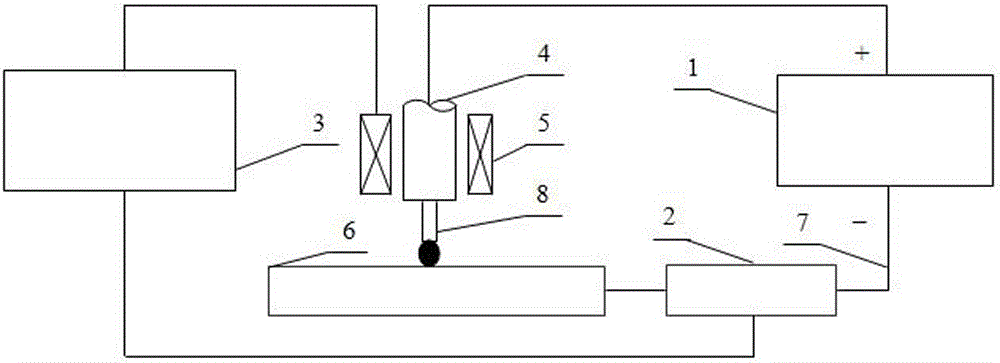

[0019] Short-circuit transition CO under synchronous magnetic field control 2 The composition of the welding system specifically includes: CO 2 Inverter welding power supply 1, Hall sensor 2, synchronous magnetic field generator 3, CO 2 Welding torch 4, excitation coil 5, workpiece 6, welding cable 7 and welding wire 8. One of them is used for short circuit transition CO 2 The devices for welding synchronous magnetic field control include: CO 2 Composed of an inverter welding power source 1, a synchronous magnetic field generator 3 and an excitation coil 5. It is characterized in that: CO 2 The inverter welding power supply 1 can output the preset welding current waveform and arc voltage waveform which are consistent with the welding current waveform and arc voltage waveform controlled by ordinary waveforms but have a higher frequency; the synchronous magnetic field generator 3 has the excitation current magnitude, magnetic field frequency and excitation coil Temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com