A kind of hybrid type alkali-free accelerator and preparation method thereof

A hybrid type, accelerator technology, applied in the field of concrete admixtures, can solve the problems of short service life of alkali-free accelerators, and achieve the effects of shortening setting time, long service life and improving hydration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation of hybrid type non-alkali quick-setting agent comprises the following steps:

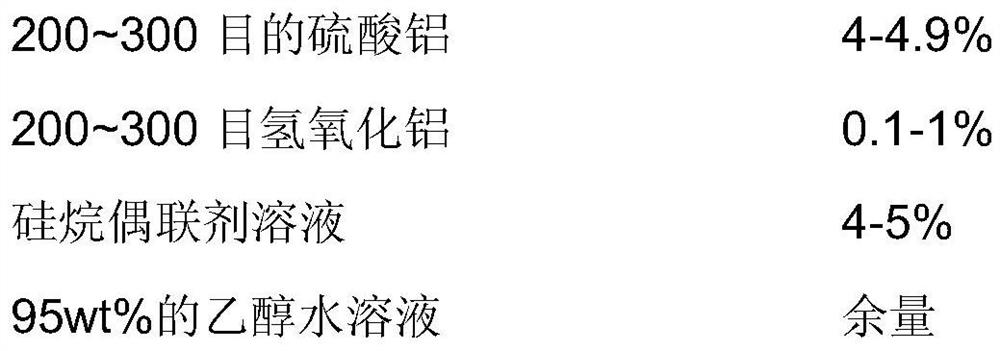

[0030] (1) Add 4.9g of 200-300mesh aluminum sulfate and 0.1g of 200-300mesh aluminum hydroxide to 90g of 95wt% ethanol aqueous solution, and then ultrasonically disperse for 1h to obtain a uniformly dispersed suspension; then add 5g of 1wt% Completely hydrolyzed γ-(2,3-epoxypropoxy)propyltrimethoxysilane ethanol solution; under nitrogen protection, stirred and reacted at 80°C for 24h, then centrifuged, washed with ethanol for 3 times, and finally Inorganic component A was obtained by vacuum drying at 60°C.

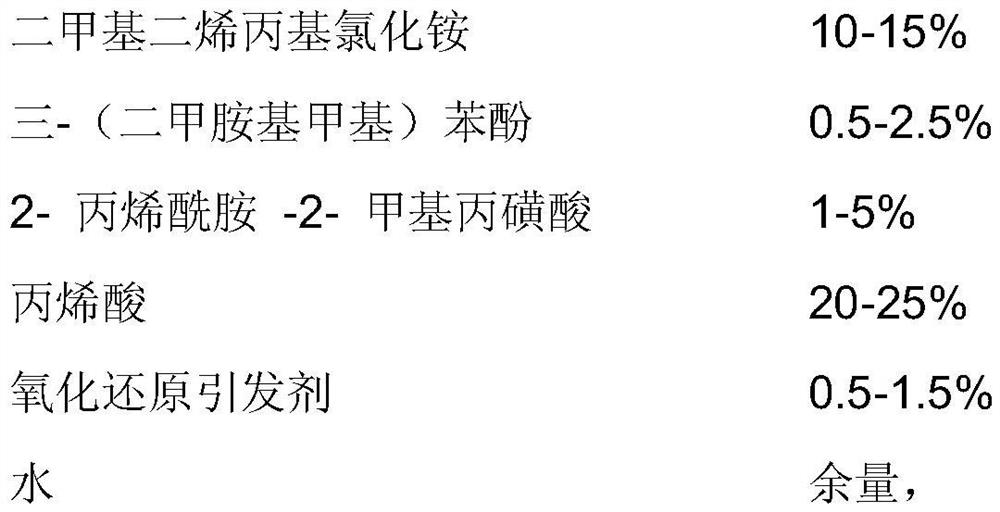

[0031] (2) Mix 10g of dimethyl diallyl ammonium chloride, 1g of 2-acrylamide-2-methylpropanesulfonic acid, 0.5g of tris-(dimethylaminomethyl)phenol, 25g of acrylic acid and 63g of water uniform, then add 0.41g ammonium persulfate and 0.09g sodium bisulfite and mix uniformly to obtain organic component B.

[0032] (3) Mix 45g of inorganic component A, 5g of diethanolamine...

Embodiment 2

[0034] The preparation of hybrid type non-alkali quick-setting agent comprises the following steps:

[0035] (1) Add 4g of 200-300 mesh aluminum sulfate and 1g of 200-300 mesh aluminum hydroxide to 95g of 95wt% ethanol aqueous solution, and then ultrasonically disperse for 1 hour to obtain a uniformly dispersed suspension; then add 4g of 3wt% complete Hydrolyzed γ-(2,3-glycidoxypropoxy)propyltrimethoxysilane ethanol solution; under nitrogen protection, stirred at 80°C for 24h, then centrifuged, washed with ethanol for 3 times, and finally 60°C Dry under vacuum to obtain the inorganic component A.

[0036] (2) Mix 15g dimethyl diallyl ammonium chloride, 5g 2-acrylamide-2-methylpropanesulfonic acid, 2.5g tris-(dimethylaminomethyl)phenol, 20g acrylic acid and 56g water uniform, then add 1.392g potassium persulfate and 0.108g sodium bisulfite and mix uniformly to obtain organic component B.

[0037] (3) Mix 50g of inorganic component A, 10g of triethanolamine, 3g of oxalic acid ...

Embodiment 3

[0039] The preparation of hybrid type non-alkali quick-setting agent comprises the following steps:

[0040] (1) Add 4.8g of 200-300 mesh aluminum sulfate and 0.2g of 200-300 mesh aluminum hydroxide to 90g of 95wt% ethanol aqueous solution, and then ultrasonically disperse for 1 hour to obtain a uniformly dispersed suspension; then add 5g of 2wt% Completely hydrolyzed γ-(2,3-epoxypropoxy)propyltrimethoxysilane ethanol solution; under nitrogen protection, stirred and reacted at 80°C for 24h, then centrifuged, washed with ethanol for 3 times, and finally Inorganic component A was obtained by vacuum drying at 60°C.

[0041] (2) Mix 12g dimethyl diallyl ammonium chloride, 3g 2-acrylamide-2-methylpropanesulfonic acid, 1g tris-(dimethylaminomethyl)phenol, 22g acrylic acid and 61g water , Then add 0.9g sodium persulfate and 0.1g sodium bisulfite and mix uniformly to obtain organic component B.

[0042] (3) Mix 50g of inorganic component A, 10g of triethanolamine, 3g of lactic acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com