Copper-doped activated carbon composite material and preparation method thereof

A composite material and activated carbon technology, applied in chemical instruments and methods, carbon compounds, other chemical processes, etc., can solve the problems of decreased activity and easy falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

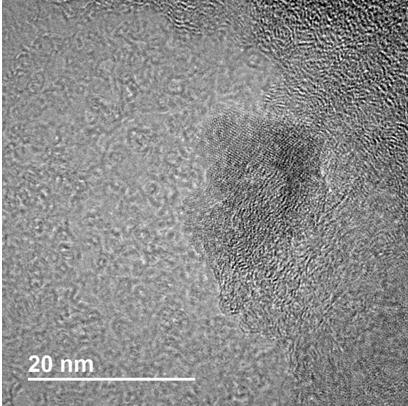

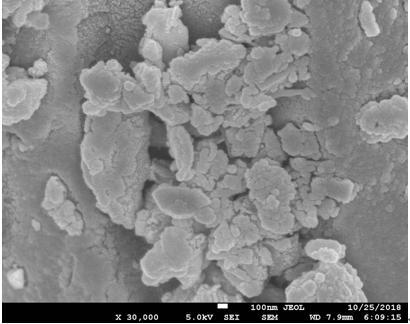

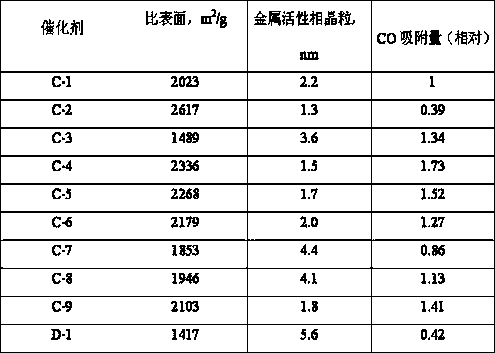

Embodiment 1

[0044] Grind 100g of petroleum coke into powder, then mix it evenly with 31.29g of copper nitrate and 300g of potassium hydroxide, place it in a microwave heating furnace with a microwave frequency of 2450MHz, and raise the temperature under a nitrogen atmosphere under the condition of a microwave power of 0.3kw Activate at 800°C for 40 minutes.

[0045] Grind the above-mentioned activated sample into powder, weigh it, mix it with deionized water at a mass ratio of 1:15, stir thoroughly, and then carry out solid-liquid separation until the pH value of the filtrate is neutral, and the obtained solid sample is placed in vacuum drying In the oven, dry at 150°C for 6 hours under vacuum conditions to obtain a composite material with a mass content of 15% Cu in terms of elements, which is denoted as C-1.

Embodiment 2

[0047] Weigh 50g of ammonium phosphate, dissolve it in 200mL of deionized water to obtain solution A; grind 100g of petroleum coke into powder, then add it to solution A, let it stand for 1.5h, then filter, and put the obtained solid sample in an oven at 110°C Dry for 5h. At 200°C, pretreat the dried solid sample with water vapor for 3 hours (the volumetric space velocity of the water vapor gas is 500 hours -1 ), then raise the temperature to 400°C, continue pretreatment for 3h, and then cool to 60°C under nitrogen protection to obtain pretreated petroleum coke.

[0048] Grind the above-mentioned pretreated petroleum coke into powder, then mix it with 9.10g of copper nitrate and 300g of sodium hydroxide, place it in a tube furnace, and raise the temperature to 800°C for 40min activation under nitrogen atmosphere.

[0049] Grind the above-mentioned activated sample into powder, weigh it, mix it with deionized water at a mass ratio of 1:15, stir thoroughly, and then carry out s...

Embodiment 3

[0051] Weigh 50g of ammonium phosphate, dissolve it in 200mL of deionized water to obtain solution A; grind 100g of petroleum coke into powder, then add it to solution A, let it stand for 1.5h, then filter, and put the obtained solid sample in an oven at 110°C Dry for 5h. At 200°C, pretreat the dried solid sample with water vapor for 3 hours (the volumetric space velocity of the water vapor gas is 800 hours -1 ), then raise the temperature to 400°C, continue pretreatment for 3h, and then cool to 60°C under nitrogen protection to obtain pretreated petroleum coke.

[0052] Grind the above-mentioned pretreated petroleum coke to powder, then mix it with 45.02g of copper nitrate, 100g of potassium bicarbonate, and 200g of potassium hydroxide, place it in a microwave heating furnace with a microwave frequency of 2450MHz, and vacuum it at a microwave power of 0.3 Under the condition of kw, the temperature was raised to 400°C and kept constant for 60 minutes, then nitrogen gas was in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com