Steel ladle turret

A technology of rotary table and ladle, applied in casting molten material container, metal processing equipment, casting equipment, etc., can solve the problems of oil leakage, damage to transmission chain, and high equipment investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

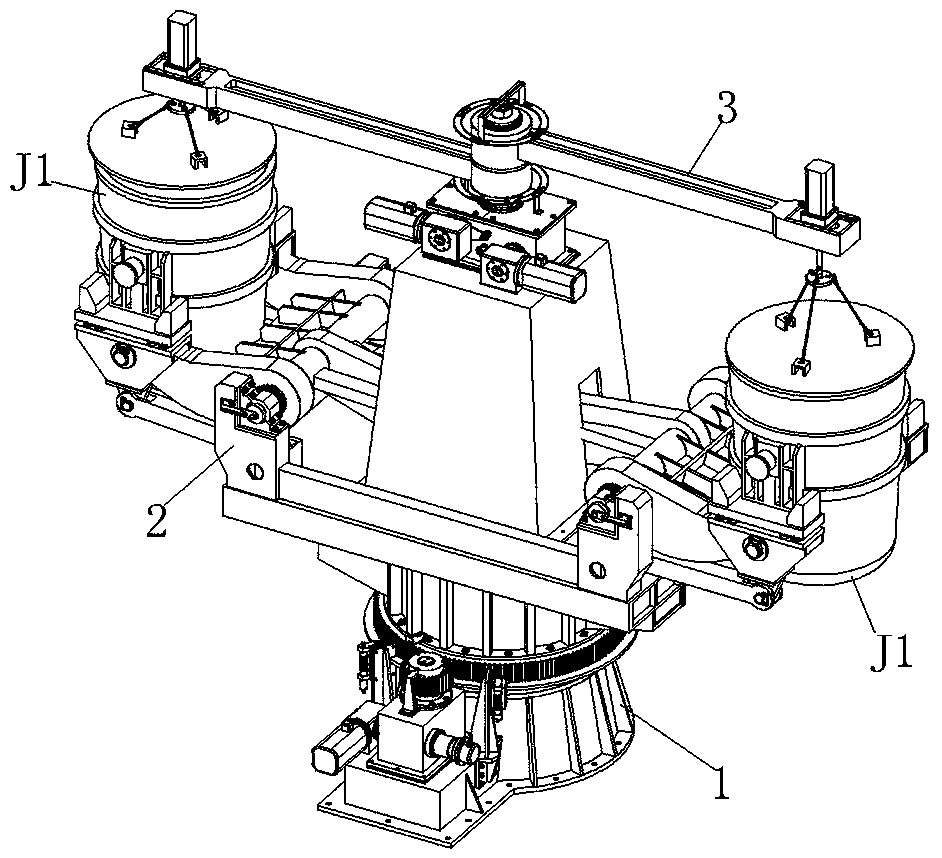

[0029] see figure 1 As shown, the present invention is composed of a rotary support device 1, a lifting device 2, and a heat preservation cover device 3. J1 in the figure is a steel ladle; The ladle J1 is placed on the lifting device 2 .

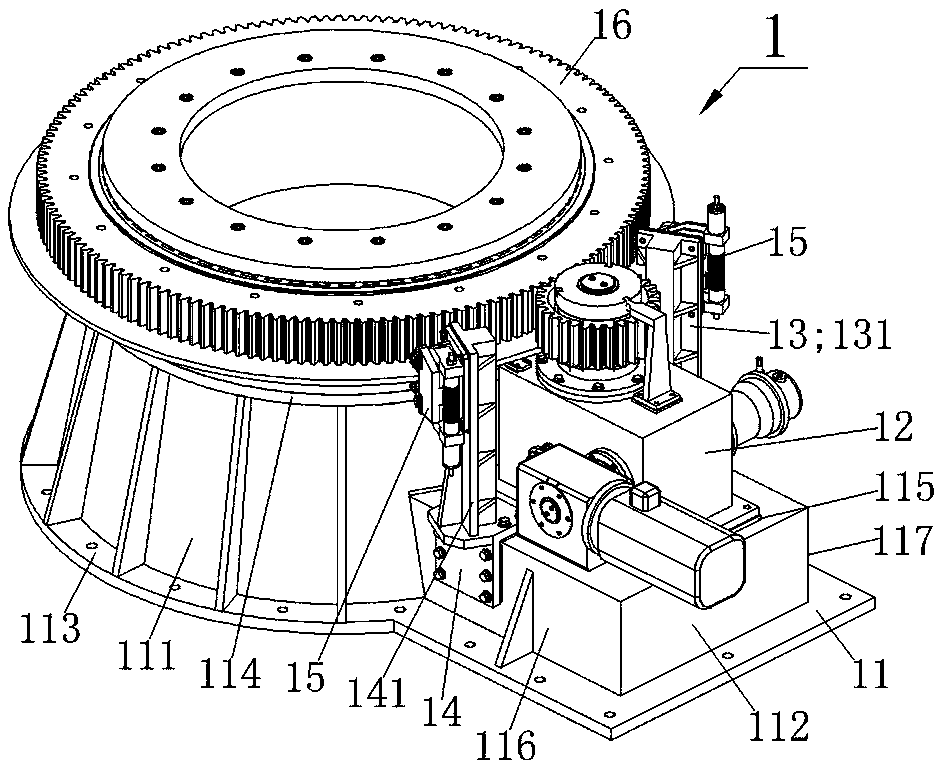

[0030] see figure 2 As shown, the slewing support device 1 is composed of a base 11, a vertical worm transmission box 12, a first brake bracket 13, a second brake bracket 14, two hydraulic disc brakes 15, and a support bearing device 16; The above-mentioned base seat 11, the main body is a combination of a conical box seat 111 and a rectangular box seat 112, an anchor handle flange 113 is arranged on the bottom periphery of the combination, and a round handle is arranged on the top of the conical box seat 111 The legal flange 114 is provided with a rectangular plywood 115 on the top surface of the rectangular box seat 112, and is respectively provided with a first facade 116 and a second facade 117 on both sides of the rectangular box sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com