Porous silicon@amorphous carbon/carbon nanotube composite material as well as preparation method and application thereof

A technology of amorphous carbon and carbon nanotubes, which is applied in the direction of active material electrodes, structural parts, electrical components, etc., can solve problems such as the inability to build a conductive network between carbon nanotubes and porous silicon, and achieve excellent lithium battery performance, low cost, and Ease of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

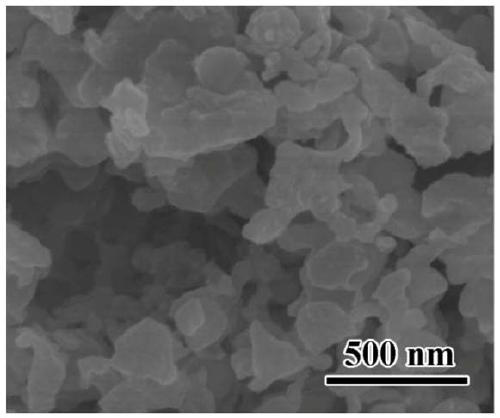

[0065] (1) Take 2g commercial Mg 2 Si is placed in a corundum boat as a raw material, and placed in a tube furnace for heat treatment. The heating rate is 20°C / min, the reaction temperature is 650°C, the reaction time is 5h, and the reaction atmosphere is air. The reacted product was placed in 0.1M hydrochloric acid and stirred for 8 hours. After the reaction, the porous silicon in the suspension was centrifuged three times with deionized water, and dried in a vacuum oven at 80° C. for later use.

[0066] (2) The porous silicon prepared in step (1) is mixed with water according to porous silicon: nickel nitrate hexahydrate: urea=1:0.5:2.5 (molar ratio) to form a solution, and the concentration of nickel ions in the solution is 0.1mol / L , subjected to constant temperature magnetic stirring at a temperature of 80° C. for 8 hours, and finally the resulting solution was centrifuged, washed three times with water and once with ethanol, and dried in vacuum at 80° C. to obtain an in...

Embodiment 2

[0080] The preparation process is exactly the same as that in Example 1, except that the heat treatment temperature in step (3) is replaced by 450°C, and the CVD treatment temperature in step (4) is replaced by 600°C.

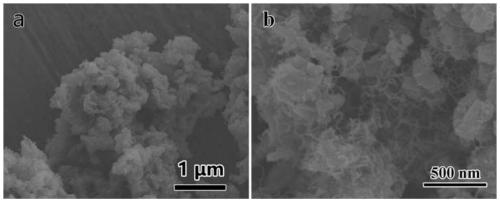

[0081] It can be seen through testing that the appearance of the product is similar to that of the final product prepared in Example 1.

Embodiment 3

[0083] The preparation process is exactly the same as that in Example 1, except that the heat treatment temperature in step (3) is replaced by 700°C, and the CVD treatment temperature in step (4) is replaced by 700°C.

[0084] It can be seen through testing that the appearance of the product is similar to that of the final product prepared in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com