Magnetic powder core rust-prevention process

A magnetic powder core and process technology, applied in metal material coating process, coating, etc., can solve the problems of large environmental pollution, high painting cost, and difficulty in realizing long-term rust prevention of magnetic powder core products, so as to achieve obvious bridging effect and prevent rust. rust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

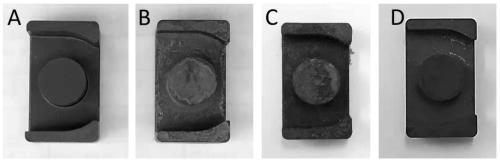

Image

Examples

Embodiment 1

[0027] Embodiment 1: a kind of antirust process of magnetic powder core, comprises the following steps:

[0028] 1) The magnetic powder core is submerged in 50wt% sodium hydroxide solution, soaked at 70°C for 30 minutes, then washed the residual lye with water, then immersed in 5wt% phosphoric acid solution, soaked at 70°C for 30 minutes, and finally washed the residual acid with water Liquid, and dry, remove the oil stains on the surface of the magnetic powder core and achieve passivation;

[0029] 2) Mix dodecyltriethoxysilane, ammonia water and ethanol to obtain an alkylsilane coupling agent solution, wherein the mass concentration of dodecyltriethoxysilane is 5%, and the mass concentration of ammonia water is 2%; then Immerse the magnetic powder core in the alkylsilane coupling agent solution at 60°C and a vacuum of -0.05Mpa, take it out and dry it after 30 minutes to achieve surface hydrophobicity;

[0030] 3) Immerse the magnetic powder core with hydrophobic surface in ...

Embodiment 2

[0031] Embodiment 2: a kind of antirust process of magnetic powder core, comprises the following steps:

[0032] 1) The magnetic powder core is submerged in a mixed solution of 45wt% sodium hydroxide and 25wt% sodium nitrate, soaked at 70°C for 30 minutes, and then washed with water to wash the residual lye, and then immersed in a mixed solution of 5wt% phosphoric acid and 5wt% nitric acid. Soak at ℃ for 30 minutes, and finally wash the residual acid solution with water and dry to remove oil stains on the surface of the magnetic powder core and achieve passivation;

[0033] 2) Mix octyltrimethoxysilane, acetic acid and water to obtain an alkylsilane coupling agent solution, in which the mass concentration of octyltrimethoxysilane is 1.5%, and the mass concentration of acetic acid is 3%; then the magnetic powder core is heated at 60°C , immersed in the alkylsilane coupling agent solution at a vacuum of -0.09Mpa, take it out and dry it after 30 minutes to achieve surface hydroph...

Embodiment 3

[0035] Embodiment 3: a kind of antirust process of magnetic powder core, comprises the following steps:

[0036] 1) The magnetic powder core is submerged in 10wt% trisodium phosphate solution, soaked at 70°C for 30min, then washed the residual lye with water, then immersed in 0.3wt% hydrochloric acid solution, soaked at 70°C for 30min, and finally rinsed with water Acid solution, and dry to remove oil stains on the surface of the magnetic powder core and achieve passivation;

[0037] 2) Mix cetyltrimethoxysilane, formic acid and methanol to obtain an alkylsilane coupling agent solution, in which the mass concentration of cetyltrimethoxysilane is 0.1%, and the mass concentration of formic acid is 0.3%; then the magnetic powder The core is immersed in the alkylsilane coupling agent solution at 60°C and the vacuum degree is -0.07Mpa, and it is taken out and dried after 30 minutes to achieve surface hydrophobicity;

[0038] 4) Immerse the magnetic powder core with hydrophobic sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com