A method for preparing a small-pore hydrophobic composite membrane for membrane distillation

A small pore size, composite membrane technology, applied in the field of membrane distillation, can solve the problems of poor hydrophobicity of micropore diameter, influence on separation effect, high osmotic resistance, etc., to achieve long-term stable operation, increase membrane distillation flux, ensure mechanical The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

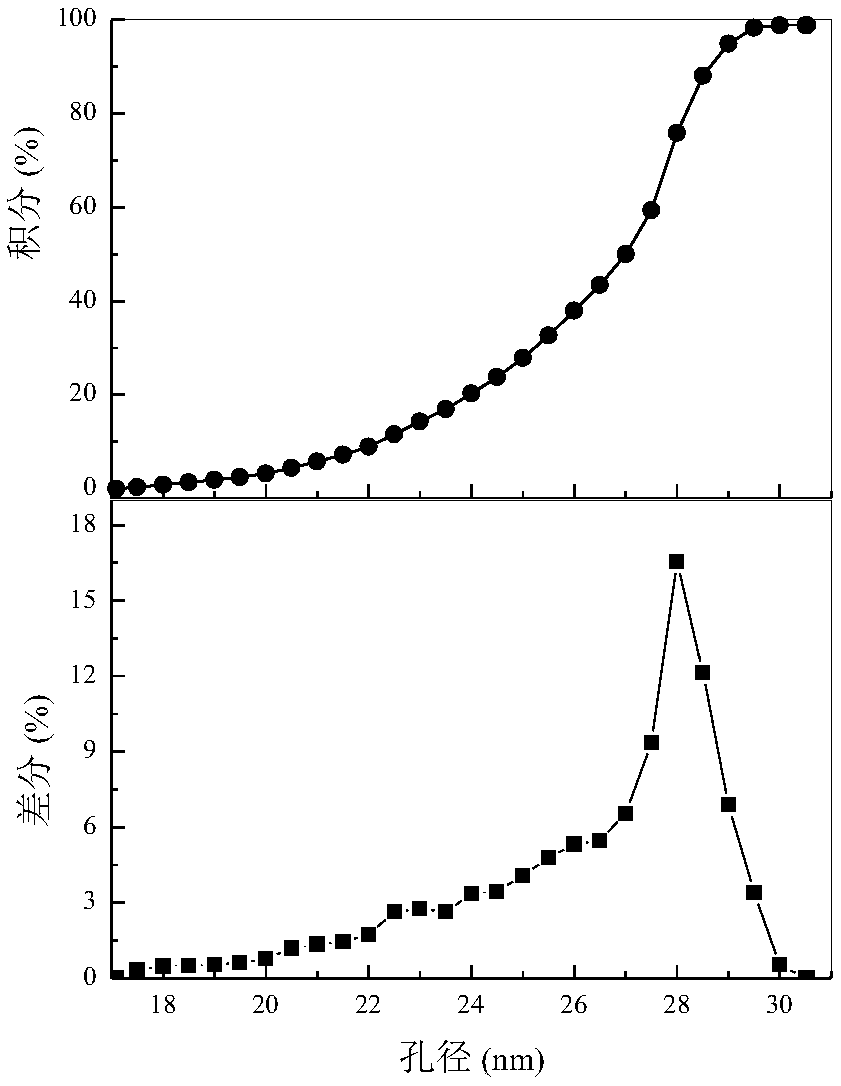

[0024] Mix 16.0wt% polysulfone and 84.0wt% N,N-dimethylacetamide, stir and heat to 80°C and keep it for 12h to obtain a uniform and transparent casting solution, and then put the casting solution in a 60°C Stand in the oven for 24 hours to fully mature and defoam, and then use; add dilute acetic acid solution dropwise to the ethanol water solution with a volume ratio of 1:1 to make the pH to 4.0, stir at 70°C for 30 minutes, and then add dropwise Silane coupling agent (methyltriethoxysilane, dodecyltrimethoxysilane, hexadecyltrimethoxysilane, n-octyltriethoxysilane or γ-methyl) with a mass concentration of 5.0% acryloxypropyltrimethoxysilane), 0.05% hydroxy silicone oil, continue to stir for 30 minutes, and set aside; under the air atmosphere with a relative humidity of 60-80%, use a scraper to put the polysulfone casting solution on the PP nonwoven Spread the surface of the cloth to form a thin layer of 50 μm, soak it in deionized water after staying for 5 seconds, take it ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com