Coke, coking method and application thereof

A technology for coke and heavy parts, applied in the field of coking, can solve the problems of lack of constant pressure coking, non-uniformity, insufficient coke strength, etc., and achieve the effect of pore wall thickness, good quality and high coke strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

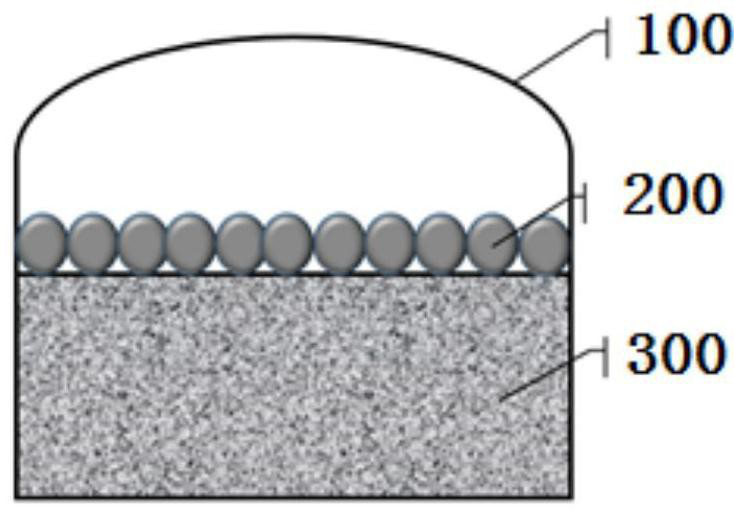

Image

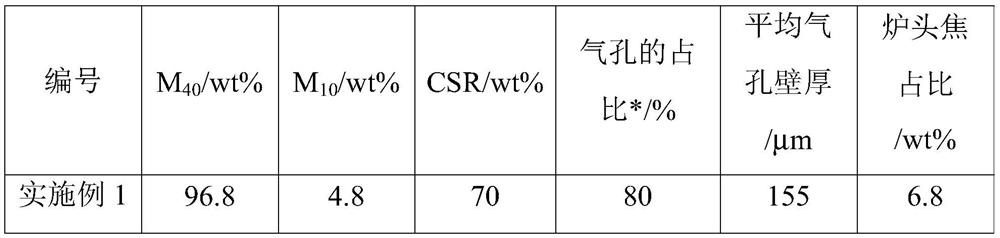

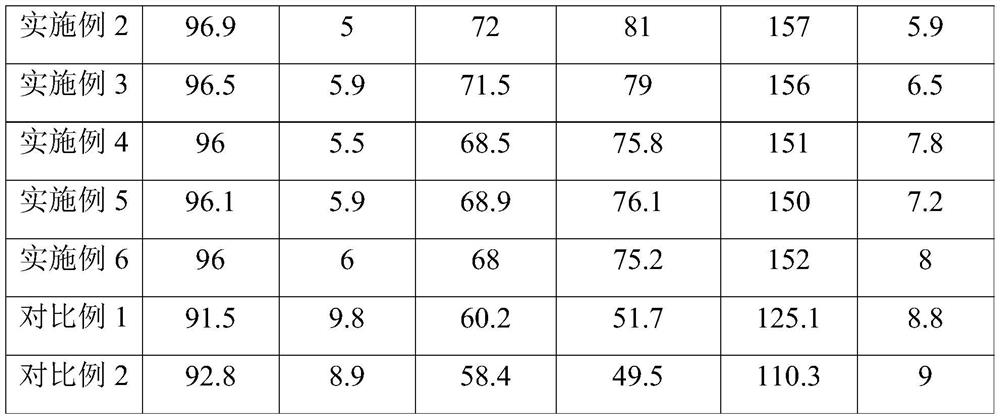

Examples

Embodiment 1

[0038] (1) Pulverizing coal raw materials, blending coal, tamping, stacking and loading coal, the height of the obtained coal block is 45cm, and the width is 35cm, and the coal block is loaded into the coking oven;

[0039] (2) Lay a layer of circular solid iron balls of the same size on the upper end face of the coal block, and the diameter of the iron balls is 10cm;

[0040] (3) Carry out heating coking to coal block, coking is carried out in 4 stages, and the conditions of each stage include:

[0041] The first stage is 50 hours, the temperature of the vault is 700°C, and the temperature of the quadruple flue is 800°C;

[0042] The second stage is 50 hours, the temperature of the vault is 850°C, and the temperature of the quadruple flue is 900°C;

[0043] The third stage is 100 hours, the temperature of the vault is 895°C, and the temperature of the quadruple flue is 900°C;

[0044] The fourth stage is 160 hours, the temperature of the vault is 895°C, and the temperature ...

Embodiment 2

[0047] (1) Pulverizing coal raw materials, blending coal, tamping, stacking and loading coal, the height of the obtained coal block is 45cm, and the width is 35cm, and the coal block is loaded into the coking oven;

[0048] (2) Lay a layer of circular solid iron balls of the same size on the upper end face of the coal block, and the diameter of the iron balls is 15cm;

[0049] (3) Carry out heating coking to coal block, coking is carried out in 4 stages, and the conditions of each stage include:

[0050] The first stage is 50 hours, the temperature of the vault is 750°C, and the temperature of the quadruple flue is 850°C;

[0051] The second stage is 100 hours, the temperature of the vault is 900°C, and the temperature of the quadruple flue is 950°C;

[0052] The third stage is 160 hours, the temperature of the vault is 905°C, and the temperature of the quadruple flue is 950°C;

[0053] The fourth stage is 195 hours, the temperature of the vault is 905°C, and the temperature...

Embodiment 3

[0056] (1) Pulverizing coal raw materials, blending coal, tamping, stacking and loading coal, the height of the obtained coal block is 45cm, and the width is 35cm, and the coal block is loaded into the coking oven;

[0057] (2) Lay a layer of circular solid iron balls of the same size on the upper end face of the coal block, and the diameter of the iron balls is 12.5cm;

[0058](3) Carry out heating coking to coal block, coking is carried out in 4 stages, and the conditions of each stage include:

[0059] The first stage is 50 hours, the temperature of the vault is 725°C, and the temperature of the quadruple flue is 825°C;

[0060] The second stage is 75 hours, the temperature of the vault is 875°C, and the temperature of the quadruple flue is 925°C;

[0061] The third stage is 130 hours, the temperature of the vault is 900°C, and the temperature of the quadruple flue is 925°C;

[0062] The fourth stage is 180 hours, the temperature of the vault is 900°C, and the temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com