A lithium battery power battery high temperature resistant microporous film material and preparation method thereof

A technology of microporous thin film and power battery, which is applied in the field of membrane materials, can solve the problems of reduced safety of lithium-ion batteries, poor electrolyte infiltration performance, and influence on battery cycle performance, and achieve good adsorption effect, good dispersion and uniform pore diameter. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

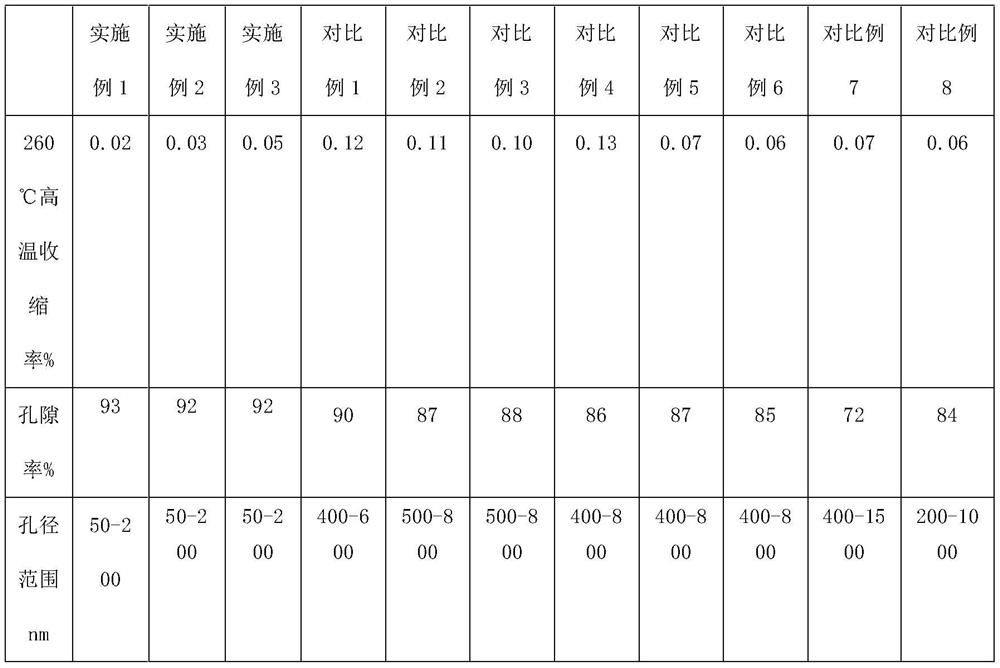

Embodiment 1

[0022] A high-temperature-resistant microporous film material for a lithium battery power battery. The raw materials include 7.5 parts by mass of polyphenylene sulfide, 25 parts of polypropylene, 2.5 parts of polysilicone, and 0.4 parts of 1,8-diaminonaphthalene. 0.2 parts of hydroquinone, 7.5 parts of mesoporous carbon, 0.75 parts of tricalcium phosphate fine powder, 3 parts of simethicone, 30 parts of paraffin oil, 0.15 parts of heat stabilizer, 0.15 parts of antioxidant .

[0023] The average pore diameter of the mesoporous carbon is 2nm, and the mesoporous carbon is amorphous mesoporous carbon. The thermal stabilizer is tridecyl phosphite. The antioxidant is antioxidant 1010.

[0024] A method for preparing a high-temperature-resistant microporous film material for a lithium battery power battery, comprising the following steps:

[0025] (1) Pour mesoporous carbon, tricalcium phosphate micropowder, simethicone oil, and paraffin oil into a blender, heat to 80°C, mix and ...

Embodiment 2

[0031] A high-temperature-resistant microporous film material for a lithium battery power battery. The raw materials include 5 parts by mass of polyphenylene sulfide, 30 parts of polypropylene, 2 parts of polysilicone, and 0.6 parts of 1,8-diaminonaphthalene. 0.1 parts of hydroquinone, 10 parts of mesoporous carbon, 0.5 parts of tricalcium phosphate fine powder, 4 parts of simethicone, 20 parts of paraffin oil, 0.2 parts of heat stabilizer, 0.1 parts of antioxidant .

[0032] The preparation method of embodiment 2 is identical with embodiment 1.

Embodiment 3

[0034] A high-temperature-resistant microporous film material for a lithium battery power battery. The raw materials include 10 parts by mass of polyphenylene sulfide, 20 parts of polypropylene, 3 parts of polysilicone, and 0.2 parts of 1,8-diaminonaphthalene. 0.3 parts of hydroquinone, 5 parts of mesoporous carbon, 1 part of tricalcium phosphate fine powder, 2 parts of simethicone oil, 40 parts of paraffin oil, 0.1 part of heat stabilizer, 0.2 part of antioxidant .

[0035] The preparation method of embodiment 3 is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com