A kind of anti-rust strengthening agent for steel fiber concrete surface and preparation method thereof

A technology of steel fiber reinforced concrete and reinforcing agent, applied in the field of building materials, can solve the problems of waste of resources and energy, unable to prevent corrosion of chloride-salted steel bars, unable to cope with corrosion of steel fibers, etc. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

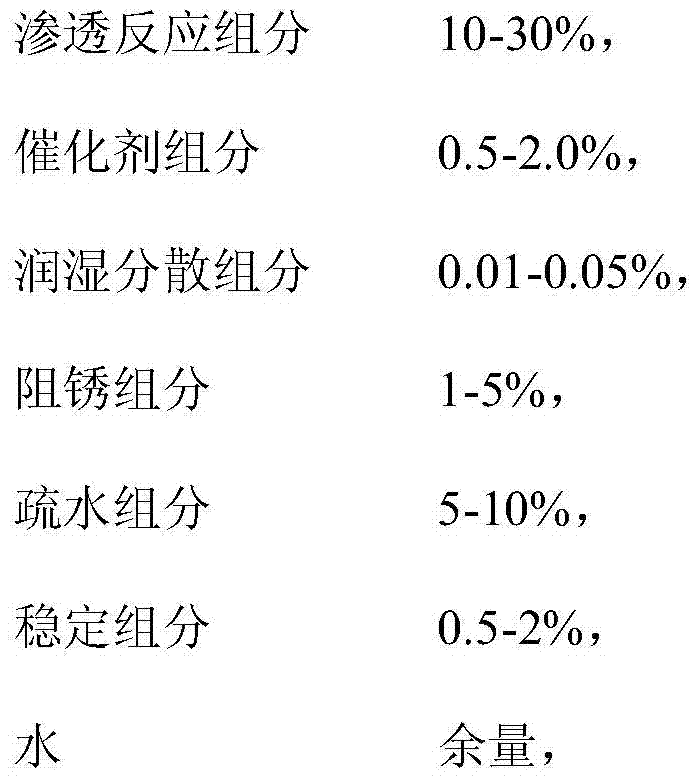

[0036] A kind of antirust strengthening agent for steel fiber concrete surface layer and its preparation method, said antirust strengthening agent is formed by mixing the following components by weight percentage:

[0037] Osmotic Reaction Component, Sodium Silicate, 30%,

[0038] Catalyst component, sodium fluorosilicate, 2.0%,

[0039] Wetting and dispersing component, sodium dodecylbenzenesulfonate, 0.05%,

[0040] Antirust component, calcium nitrite and ethanolamine, 5%,

[0041] Hydrophobic component, potassium methyl silicate, 7%;

[0042] Stabilizing component, isopropanol, 1.5%;

[0043] The balance is water, and the total weight is calculated as 100%.

[0044] The preparation method of the anti-rust enhancer: first weigh half of the amount of water and place it in the reactor, add the osmotic reaction components, and stir for 10 minutes at a stirring speed of 60r / min; then weigh the other half of the water and place it in the reactor , add the catalyst component an...

Embodiment 2

[0047] A kind of antirust strengthening agent for steel fiber concrete surface layer and its preparation method, said antirust strengthening agent is formed by mixing the following components by weight percentage:

[0048] Osmotic Reaction Component, Potassium Silicate, 25%,

[0049] Catalyst component, magnesium fluorosilicate, 0.9%,

[0050] Wetting and dispersing component, lecithin and triisopropanolamine, 0.03%,

[0051] Antirust component, sodium molybdate and diethanolamine, 1%,

[0052] Hydrophobic component, sodium methyl silicate, 5%;

[0053] Stabilizing component, diethylhexanol, 0.5%;

[0054] The balance is water, and the total weight is calculated as 100%.

[0055] The preparation method of the anti-rust enhancer: first weigh half of the amount of water and place it in the reactor, add the osmotic reaction components, and stir for 10 minutes at a stirring speed of 60r / min; then weigh the other half of the water and place it in the reactor , add the catalyst...

Embodiment 3

[0058] A kind of antirust strengthening agent for steel fiber concrete surface layer and its preparation method, said antirust strengthening agent is formed by mixing the following components by weight percentage:

[0059] Osmotic Reaction Component, Lithium Silicate, 10%,

[0060] Catalyst component, ammonium fluorosilicate, 0.5%,

[0061] Wetting and dispersing component, perfluorosurfactant, 0.01%,

[0062] Antirust component, sodium benzoate and N-methylethanolamine, 2%,

[0063] Hydrophobic component, sodium methyl siliconate, 10%;

[0064] Stabilizing component, diisobutylmethanol, 2.0%;

[0065] The balance is water, and the total weight is calculated as 100%.

[0066] The preparation method of the anti-rust enhancer: first weigh half of the amount of water and place it in the reactor, add the osmotic reaction components, and stir for 10 minutes at a stirring speed of 60r / min; then weigh the other half of the water and place it in the reactor , add the catalyst com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| penetration depth | aaaaa | aaaaa |

| penetration depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com