Rear steel plate spring for truck

A technology of leaf springs and steel plates, applied in the field of leaf springs, can solve the problems of loss of durability of spring steel plates, impact and corrosion of spring steel plates, reduction of strength of leaf springs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

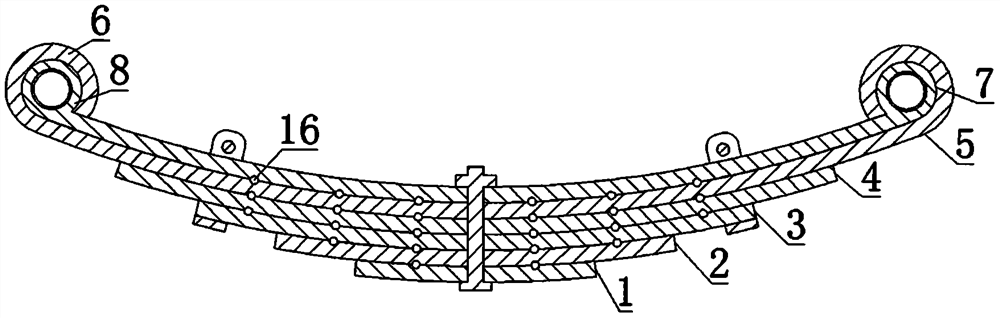

[0030] As a preferred embodiment of the present invention, the ear 6 is installed on the outside of the ear 8, and the number of the ear 6 and the ear 8 are two.

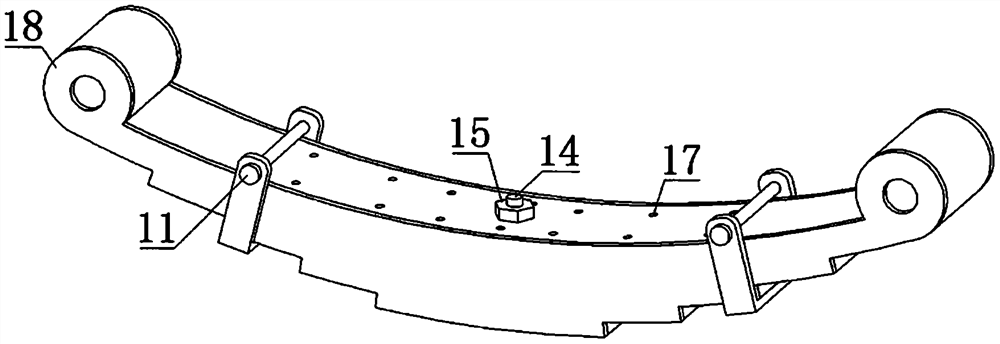

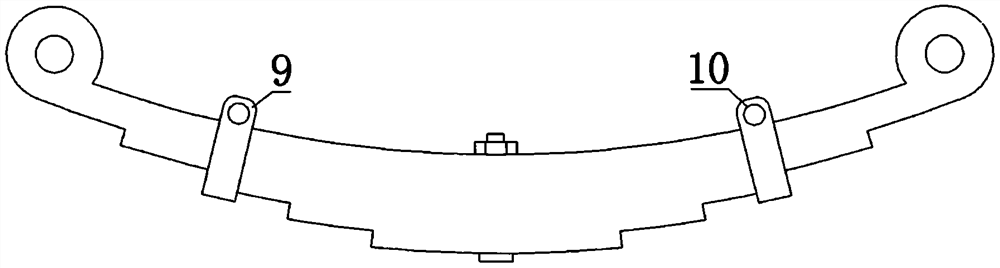

[0031] As a preferred embodiment of the present invention, the protective plate 18 is fixed on both sides of the steel plates 1 to 6 7 through the fixing frame 9, and the number of the protective plate 18 and the fixing frame 9 are two.

[0032] As a preferred embodiment of the present invention, in the steel plate one 1 and the steel plate six 7, a cooling hole 16 is drilled between every two steel plates, and the top of the steel plate six 7 is drilled with a cooling hole 2 17, and the heat dissipation Hole 2 17 runs through to heat dissipation hole 1 16 between steel plate 1 and steel plate 2 2 .

[0033] As a preferred embodiment of the present invention, the rotating disk 21 is provided with a slide groove 28, and the support rod 22 is provided with a limit rod 29, and the support rod 22 is fixed on the end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com