Extra-thick container steel plate with excellent low-temperature impact toughness at center

A low-temperature impact toughness and steel plate technology, applied in the field of iron-based alloys, can solve the problems of unstable low-temperature impact toughness of the core, unable to meet the needs of large-scale chemical energy equipment, and high-parameter development, so as to avoid structural abnormalities and shortening. Delivery cycle, the effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

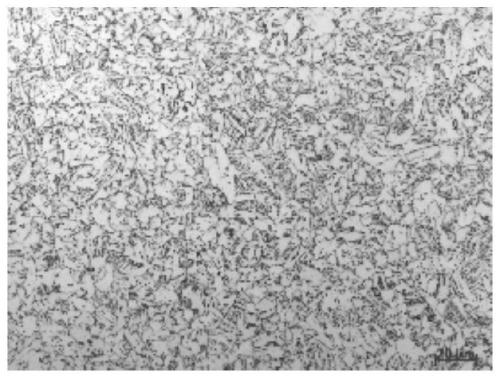

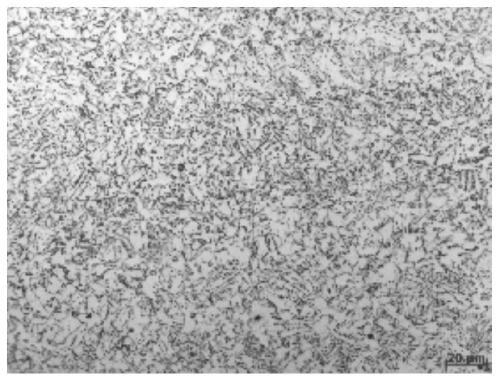

[0031] The present invention will be further described in detail below in conjunction with the embodiments of the accompanying drawings. The embodiments described below are exemplary and are intended to explain the present invention, but should not be construed as limiting the present invention. In addition, comparative examples are listed to highlight the examples.

[0032] The smelting chemical composition of this example and the comparative example is shown in Table 1 (wt%), and the remainder is Fe and inevitable impurity elements.

[0033] Table 1

[0034] elementC Si MnPS Nb+V+Als Ti NiH CEV (V+Nb+Als) / [Ti] Example 10.130.201.500.0050.0010.0840.0150.350.00010.425.6 Example 20.140.211.520.0060.0020.0610.0140.320.00010.424.4 Comparison 0.160.251.400.0120.0060.0300.0180.450.00030.441.7

[0035] The above examples and comparative examples are all smelted in a converter, and then subjected to deep desulfurization and refining in a ladle furnace, and finally to a vacuum furnace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com