High-hardness color plate and preparation method thereof

A high-hardness, color-plate technology, applied in coatings, metal material coating processes, epoxy resin coatings, etc., can solve the problems of increasing processing difficulty, easy agglomeration of inorganic fillers, and large compatibility, so as to reduce gloss Degree, improve product appearance, good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

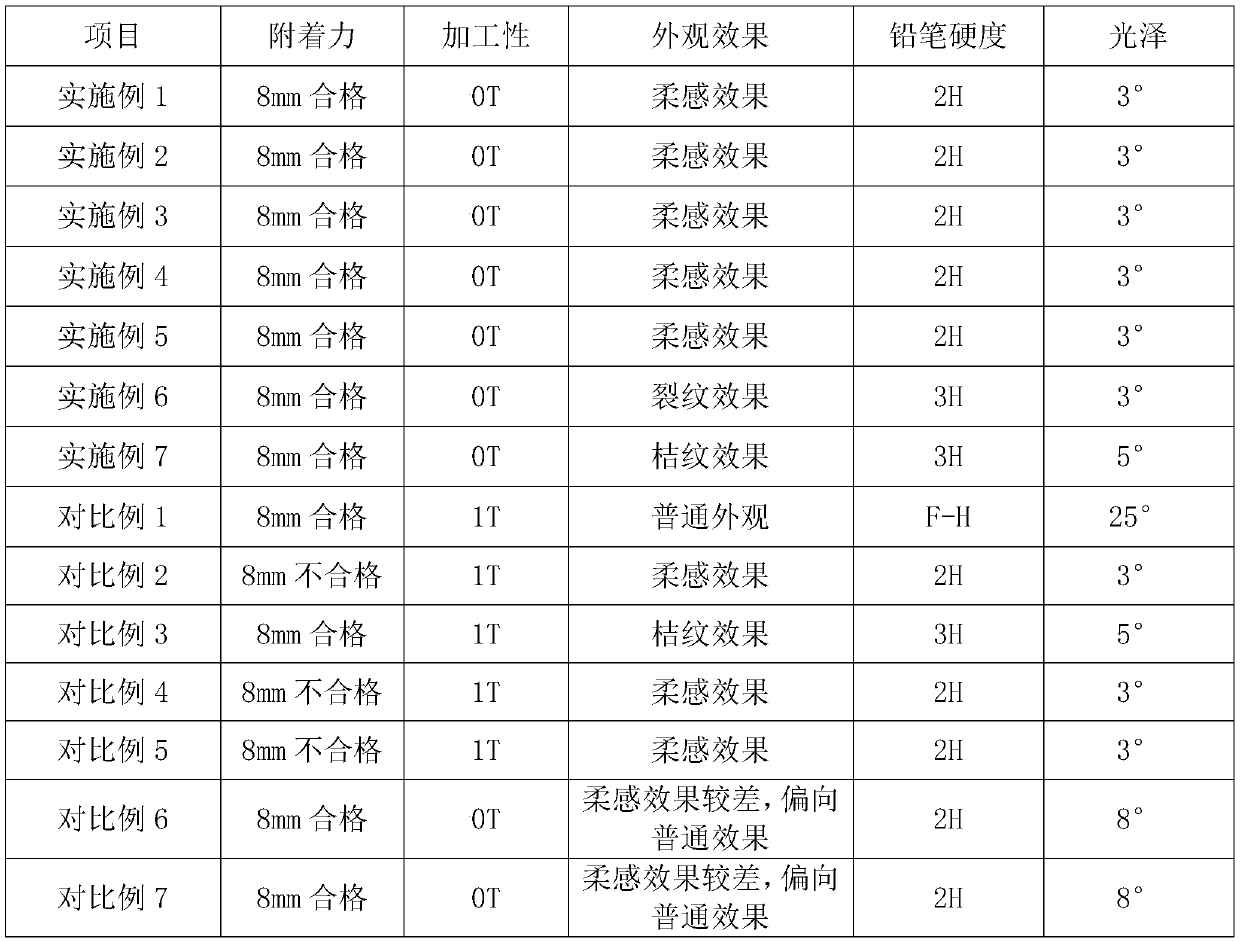

Examples

preparation example Construction

[0042] Preparation example of talc powder The talc powder in the following preparation examples is selected from the talc powder with a fineness of 3000 mesh provided by Shanggao County Mingzheng Plastic Chemical Co., Ltd.

[0043] Take 100kg of talc powder, add 1.5kg of silane coupling agent KH570 into it, and stir for 0.5-1h at a temperature of 60-80°C to obtain surface-treated talc powder.

[0044] Preparation example of organic amine liquid curing agent The cycloaliphatic epoxy resin in the following preparation examples is selected from the cycloaliphatic epoxy resin of model 2021P provided by Daicel, Japan.

preparation example 1

[0045] Preparation example 1 of organic amine liquid curing agent: ①Take 15kg alicyclic epoxy resin and 15kg isopropanol, heat it to 80-90°C, add 2kg4,4'-diaminodiphenyl ether, keep warm for 0.5h, Obtain modified epoxy resin solution;

[0046] ②Take 13kg of isophoronediamine and 20kg of isopropanol, and heat it to 60°C to obtain an organic amine solution;

[0047] ③ Add the modified epoxy resin solution dropwise to the organic amine solution within 1 hour, and react for 1 hour at a temperature of 80°C; then add 2 kg of phthalic anhydride, stir and react for 30 minutes, heat to recover isopropanol, and then add 20kg of deionized water was stirred evenly to obtain an organic amine liquid curing agent.

preparation example 2

[0048] Preparation example 2 of organic amine liquid curing agent: ①Take 15kg of alicyclic epoxy resin and 15kg of isopropanol, heat it to 85°C, add 2kg of 4,4'-diaminodiphenyl ether, and keep it warm for 1 hour to obtain a modified Epoxy resin solution;

[0049] ②Take 13kg of isophoronediamine and 20kg of isopropanol, and heat it to 63°C to obtain an organic amine solution;

[0050] ③ Add the modified epoxy resin solution dropwise to the organic amine solution within 1.3 hours, and react for 2 hours at a temperature of 85°C; then add 2kg of phthalic anhydride, stir and react for 35 minutes, heat to recover isopropanol, and then Add 20kg of deionized water and stir evenly to obtain an organic amine liquid curing agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com