Environment-friendly carbon-free dry material

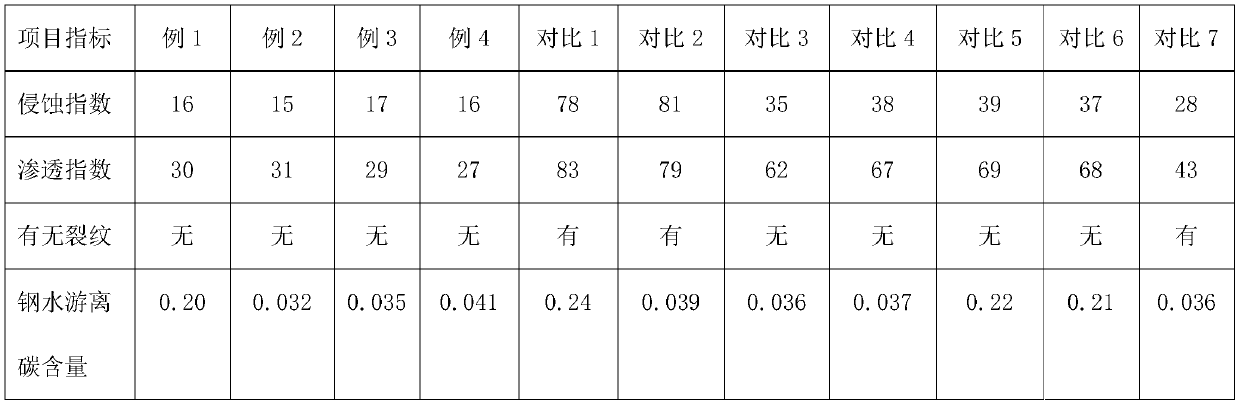

A dry material and environmentally friendly technology, applied in the field of refractory materials, can solve the problems of harming the health of operators, reducing the quality of molten steel, polluting the environment, etc., achieving the effect of low erosion index, reducing carbon pollution, and improving cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation process of above-mentioned sintered magnesia is as follows:

[0022] Take magnesite as the raw material, first use a common mill to grind the raw material to 200 mesh, put the ground raw material ore powder into the flotation tank for wet flotation purification, and obtain magnesite concentrate powder;

[0023] The above-mentioned magnesite concentrate powder is ultra-finely pulverized and ground by a stirring ball mill to obtain ultra-fine magnesite concentrate powder, which is then pressed into shape under a pressure of 400MPa;

[0024] Put the shaped ultra-fine magnesite concentrate into a rotary kiln, first calcinate at 1500°C for 1.5 hours, then raise the temperature to 2000°C for 2 hours, then lower the temperature to 1800°C and keep it for 5 hours to obtain sintered magnesia.

[0025] In the following examples, the above method was used to prepare sintered magnesia.

[0026] When using the above-mentioned carbon-free dry material, mix the ingredi...

Embodiment 1

[0028] An environment-friendly carbon-free dry material, including sintered magnesia, hydrated sodium metasilicate, hydrated magnesium sulfate and borides, each component is 95% by weight of sintered magnesia, hydrated sodium metasilicate is 1%, Magnesium sulfate hydrate is 2%, and boride is 2%.

[0029] Wherein the hydrated sodium metasilicate is taken from the mixture of sodium metasilicate nonahydrate, sodium metasilicate heptahydrate and sodium metasilicate pentahydrate with a molar ratio of 1:1; the magnesium sulfate hydrate is seven A mixture of magnesium sulfate hydrochloride and magnesium sulfate trihydrate, the molar ratio of the magnesium sulfate heptahydrate and magnesium sulfate trihydrate is 2:1; the boride is boric acid.

[0030] When using the above-mentioned carbon-free dry material, mix the ingredients first, and then spread the mixed dry material on the inner surface of the tundish (the specific method can be to spread the dry material on the bottom of the tu...

Embodiment 2

[0032] An environment-friendly carbon-free dry material, including sintered magnesia, hydrated sodium metasilicate, hydrated magnesium sulfate and borides, each component is 87% by weight of sintered magnesia, hydrated sodium metasilicate is 5%, Magnesium sulfate hydrate is 7%, and boride is 1%.

[0033] Wherein, the hydrated sodium metasilicate is obtained from a mixture of sodium metasilicate nonahydrate and sodium metasilicate pentahydrate at a molar ratio of 1:1; the magnesium sulfate hydrate is composed of magnesium sulfate heptahydrate and magnesium sulfate trihydrate The mixture of magnesium sulfate heptahydrate and magnesium sulfate trihydrate has a mol ratio of 1:2; the boride is boric acid.

[0034] When using the above-mentioned carbon-free dry material, mix the ingredients first, and then spread the mixed dry material on the inner surface of the tundish (the specific method can be to spread the dry material on the bottom of the tundish first, and then Put the work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com