MXene black phosphorene composite sponge and preparation method thereof

A technology of composite sponge and phosphorene, applied in the field of nanomaterials, can solve the problems of loss of excellent performance of pure MXene materials, easy mutual aggregation of sheets, loss of high specific surface area, etc., and achieve good photoelectric characteristics, excellent performance, and simple equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] Another aspect of the embodiments of the present invention provides the preparation method of the described MXene purple phosphorene composite sponge, which includes:

[0061] Add an appropriate proportion of phosphorene into the MXene dispersion under an inert atmosphere, and through a mixing process, obtain the MXene phosphorene composite dispersion;

[0062] Add a crosslinking agent to the above-mentioned MXene purple phosphorene composite dispersion, and let it stand for a period of time to make it shape;

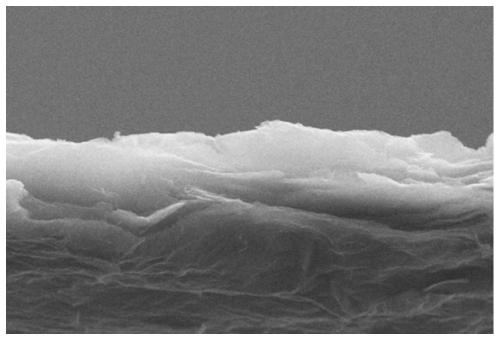

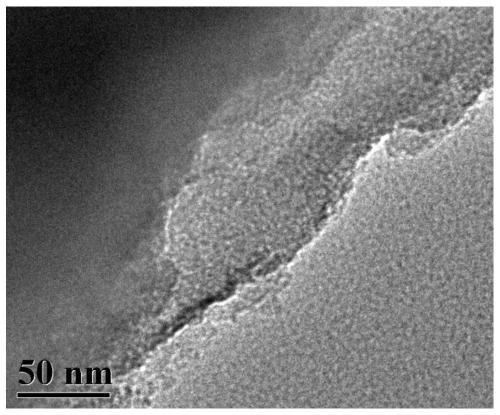

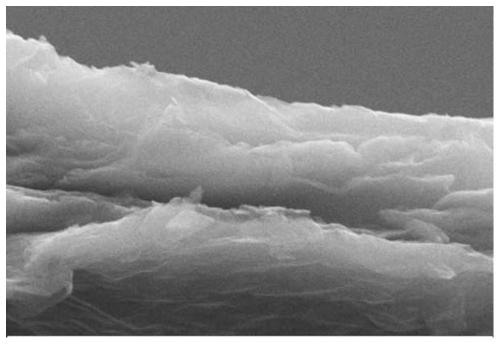

[0063] The MXene phosphorene composite wet sponge with a certain shape obtained above is processed through a cycle freeze-drying process to obtain the MXene phosphorene composite sponge.

[0064] As one of the preferred schemes, the concentration of the MXene dispersion is 0.05mg / ml-5mg / ml.

[0065] Preferably, the described MXene dispersion comprises Ti 2 CT x , Nb 2 CT x , V 2 CT x 、TiNbCT x 、Ti 3 CNT x 、Ti 3 C 2 T x 、 Ta 4 C 3 T x or Nb 4 C 3...

Embodiment 1

[0098] (1) Preparation of MXene phosphorene mixed solution: 5 mg of phosphorene was added to 10 ml of 5 mg / ml MXene aqueous dispersion, and then argon gas was passed into the dispersion at a rate of 10 ml / min for 30 min. The dispersion liquid passed through the inert gas was magnetically stirred in a cold trap at 0° C. for 1 hour, and then placed in an ice-water bath with 100 W power for 3 hours. Finally, the ultrasonic dispersion was placed in a cold trap at -10°C for 1 hour, and then taken out and naturally returned to room temperature to obtain a uniformly dispersed MXene purple phosphorene composite dispersion.

[0099] (2) Preparation of MXene purple phosphorene composite sponge: add 1% by mass of MXene diethylamine to the mixed dispersion, and let it stand at 25° C. for 36 hours to obtain a bulk composite sponge. The composite sponges were then soaked in deionized water for 4 hours and repeated 20 times. Freeze the cleaned composite sponge in a -60°C cold trap for 30 mi...

Embodiment 2

[0102] (1) Preparation of MXene phosphorene mixed solution: Add 1 mg of phosphorene into 50 ml of 1 mg / ml MXene aqueous dispersion, and then blow argon into the dispersion at a rate of 200 ml / min for 120 min. The dispersion liquid passed through the inert gas at 0 ℃ Magnetic stirring was used in a cold trap for 2 hours, and then placed in an ice-water bath with 600W power for 0.5 hours of ultrasonication. Finally, the liquid will be ultrasonically dispersed at -10 ℃ The cold trap was left to freeze for 1.5 hours, and then it was taken out and naturally returned to room temperature to obtain a uniformly dispersed MXene phosphorene composite dispersion.

[0103] (2) Preparation of MXene purple phosphorene composite sponge: 1% of the mass of MXene diethylamine was added to the mixed dispersion liquid, and the mixture was left to stand at 25°C for 24 hours to obtain a block composite sponge. The composite sponges were then soaked in deionized water for 6 hours and repeated 10 ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Film diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com