Silk protein-based multi-functional nanofiber membrane for smoke filtration and preparation method thereof

A fibroin fiber and nanofiber membrane technology, which is applied in the preparation of spinning solution, single-component fibroin rayon, fiber processing, etc., can solve the problem of low mechanical properties of nanofiber membranes, poor self-supporting mechanical properties, Membrane mechanical properties are poor and other problems, to achieve long-term stable piezoelectric effect, good air permeability, good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

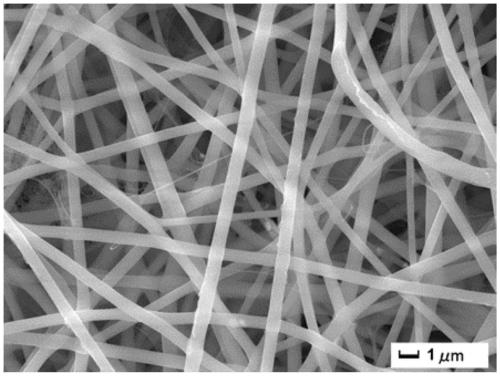

[0036] Embodiment 1: the preparation of pure silk protein nanofiber film

[0037] Firstly, boil the ginseng in 0.05wt% sodium carbonate aqueous solution for 60 minutes to remove sericin, wash it to obtain silk protein, and dry the silk protein in a vacuum oven at 35°C for 1 day. The fibroin fibers were then placed in CaCl 2 / FA(CaCl 2 3% by mass) in the system at 25°C for 60 minutes, the concentration of silk protein is 8wt%, and then it is placed in a petri dish to dry to form a film, and the dried film is soaked in deionized water, and the deionized water is constantly replaced until the CaCl 2Completely remove, secondary dry. The obtained silk protein film was dissolved in anhydrous formic acid with a mass fraction of 98% to obtain an 8 wt% silk protein formic acid solution. Then, using electrospinning technology, the spinning voltage is 20kV, the receiving distance is 12cm, the advancing speed of the silk protein formic acid solution is 0.5ml / h, the rotating speed of th...

Embodiment 2

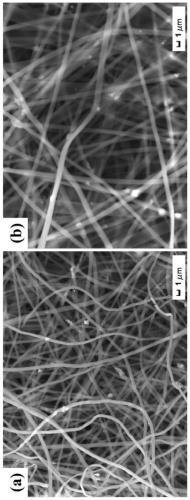

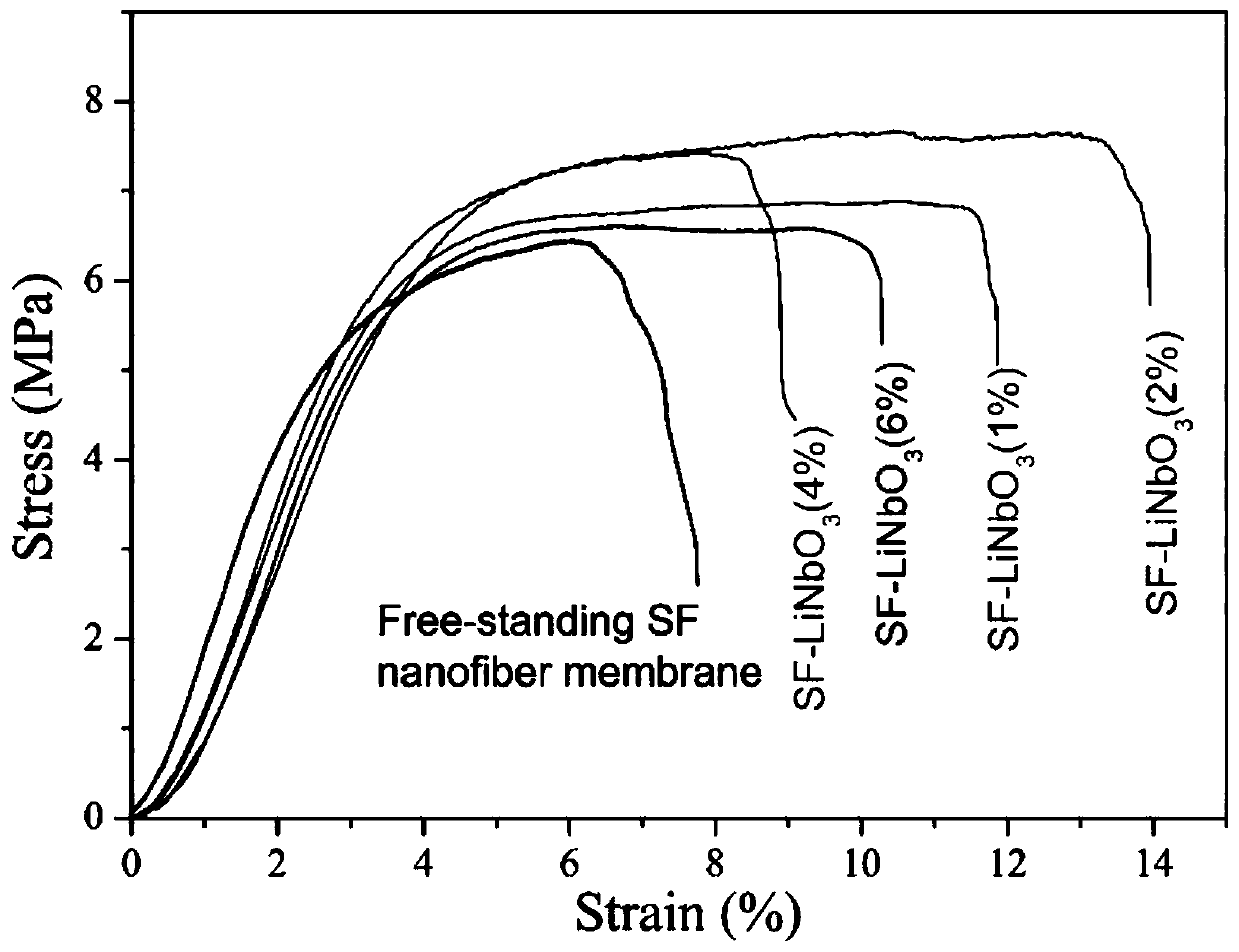

[0038] Example 2: Preparation of degradable silk protein-based multifunctional nanofiber composite membrane

[0039] Firstly, boil the ginseng in 0.05wt% sodium carbonate aqueous solution for 60 minutes to remove sericin, wash it to obtain silk protein, and dry the silk protein in a vacuum oven at 35°C for 1 day. The fibroin fibers were then placed in CaCl 2 / FA(CaCl 2 3% by mass) in the system at 25°C for 60 minutes, the concentration of silk protein is 8wt%, and then it is placed in a petri dish to dry to form a film, and the dried film is soaked in deionized water, and the deionized water is constantly replaced until the CaCl 2 Completely remove, secondary dry. Add 1.2g of the obtained silk protein film and 0.024g of lithium niobate nanoparticles into 13.8g of 98% anhydrous formic acid, so that the concentration of silk protein in the spinning solution is 8wt%, and the doping amount of lithium niobate is 2wt%. Stir for 2 hours to obtain a homogeneous suspension. Then, u...

Embodiment 3

[0040] Example 3: Preparation of degradable silk protein-based multifunctional nanofiber composite membrane

[0041] Under the condition that the other conditions of Example 2 are kept constant, a comparative test is established as follows: 1.2 g of the obtained silk protein film and 0.072 g of lithium niobate nanoparticles are added to 13.8 g of 98% anhydrous formic acid to make the silk protein in the spinning solution The concentration is 8wt%, and the doping amount of lithium niobate is 6wt%, and stirred for 2 hours to obtain a uniform suspension. Then, by using the electrospinning technology, the self-supporting silk protein-based multifunctional nanofiber composite membrane can be obtained by controlling the spinning time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Stress | aaaaa | aaaaa |

| Strain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com