Method for preparing oxide dispersion strengthened steel through high-flux continuous smelting

A dispersion strengthening and oxide technology, applied in the field of metal materials, can solve the problems of long period of optimization of alloy composition, inability to meet the influence of the control of composition, structure, size and distribution, poor stability between batches, etc., so as to reduce the development time. and cost, high-throughput continuous preparation, and the effect of reducing R&D costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] Put 10mg, 30mg, 60mg and 90mg Fe in 4 crucibles respectively 2 o 3 Powder. Its concrete preparation method comprises the following steps:

[0060] Add 10mg, 30mg, 60mg and 90mg Fe into the numbered crucible 2 o 3 powder, and rest the crucible on the multi-crucible platform of the high-throughput melting equipment. Among them, high-throughput melting equipment is equipment for vacuum induction continuous melting and high-throughput preparation of metal materials, including automatic feeding device, multi-crucible platform, induction melting device, PLC control device and vacuum for realizing vacuum & atmosphere melting environment & atmosphere system.

[0061] Place the prefabricated mother steel bar on the automatic feeding device and start the vacuuming operation. When the vacuum degree reaches 0.01Pa, the feeding device & melting device are powered on.

[0062] After being energized, the automatic feeding device drives the steel rod to deliver to the smelting coi...

Embodiment 1

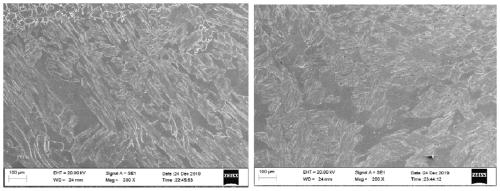

[0064] Please also see attached figure 1 , a CNS I ODS steel with different microalloy compositions prepared by using the above equipment and method, wherein the percentages of each element of the master alloy to the total mass are: C: 0.08%, Cr: 9.0%, W: ~2.1% , N: 0.05%, Si, 0.1%, Nb: 0.1%, Mo: 0.3% V, 0.5%, B<0.001%, S<0.003%, P<0.005%, Y, 0.3%, Fe balance.

[0065] The percentages of each element in the total mass of the four ODS steels produced are:

[0066]1. C: 0.08%, Cr: 9.0%, W: ~2.1%, N: 0.05%, Si, 0.1%, Nb: 0.1%, Mo: 0.3%, V, 0.5%, B<0.001%, S<0.003 %, P<0.005%, Y, 0.3%, Fe balance.

[0067] 2. C: 0.08%, Cr: 9.0%, Mn: 0.45%, W: ~2.1%, Nb: 0.1%, Mo: 0.3%, N: 0.05%, Si: 0.1%, V: 0.5%, B<0.001 %, S<0.003%, P<0.005%, Y, 0.3%, Fe balance.

[0068] 3. C: 0.08%, Cr: 9.0%, Mn: 0.45%, W: ~2.1%, Nb: 0.1%, Mo: 0.3%, N: 0.05%, Ta, 0.10%, Si, 0.1%, V: 0.5 %, B<0.001%, S<0.003%, P<0.005%, Y, 0.3%, Fe balance.

[0069] 4. C: 0.08%, Cr: 9.0%, Mn: 0.45%, W: ~2.1%, N: 0.05%, Nb...

Embodiment 2

[0076] The prepared CNS I ODS steel, the percentage of the master alloy containing rare earth elements in the total mass: C: 0.08%, Cr: 9.0%, N: 0.05%, Mn: 0.45%, Ta: 0.10%, B<0.001% , S<0.003%, P<0.005%, Y: 0.3%, Fe balance.

[0077] Put 10mg, 30mg, 60mg, 90mg, 120mg, 150mg, 180mg, 210mg, 240mg, 270mg Fe2O3 powder into 12 crucibles respectively. Its specific preparation method comprises the following steps:

[0078] Add 10mg, 30mg, 60mg, 90mg, 120mg, 150mg, 180mg, 210mg, 240mg, 270mg of Fe into the numbered crucible 2 o 3 powder, and rest the crucible on the multi-crucible platform of the high-throughput melting equipment. Among them, high-throughput melting equipment is equipment for vacuum induction continuous melting and high-throughput preparation of metal materials, including automatic feeding device, multi-crucible platform, induction melting device, PLC control device and vacuum for realizing vacuum & atmosphere melting environment & atmosphere system.

[0079] Pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com