A bismuth vanadate electrode co-modified by mof and hrgo and its preparation method and application

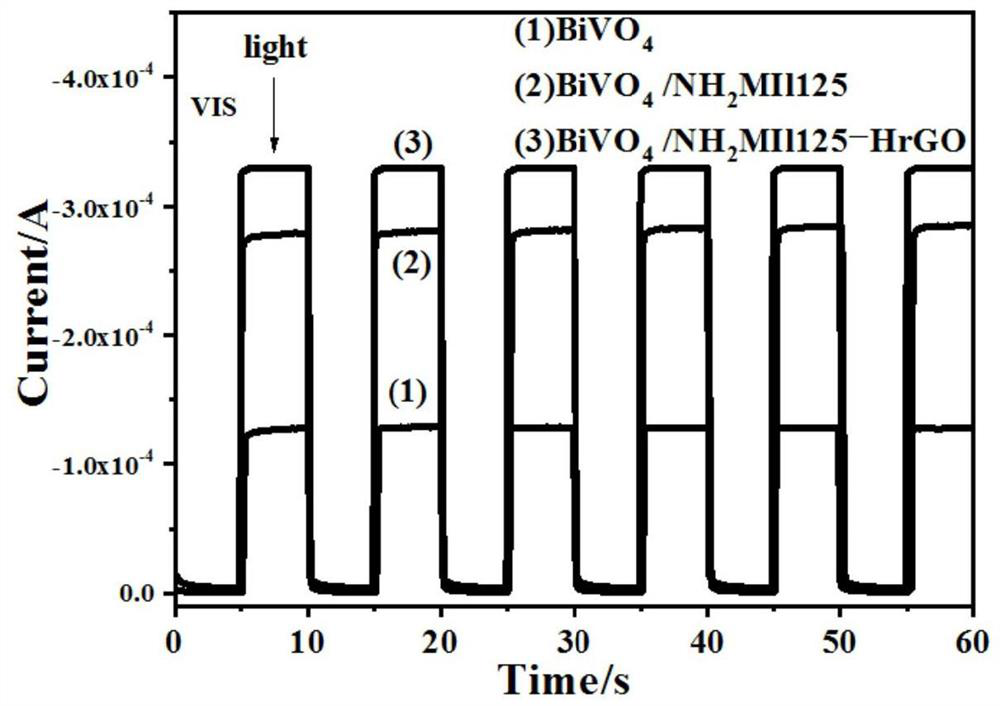

A technology of bismuth vanadate and co-modification, applied in chemical instruments and methods, electrochemical water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems that cannot be implemented, cannot be directly applied to electrode preparation, etc., and achieve high gloss current, good photocatalytic activity, and low charge transfer resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A preparation method of a photoelectric catalytic electrode, comprising the following steps:

[0041] (1) 0.3234g Bi(NO) 3 ·5H 2 O was dissolved in 1 mL of concentrated nitric acid (70 wt%), then 2 mL of distilled water was added, and 0.078 g of NH was added after mixing evenly. 4 VO 3 And 0.167g of polyvinyl alcohol (PVA, 99%) was dissolved in the above solution, and the seed solution was obtained by ultrasonic for 30min.

[0042] (2) Smear 20 μL of seed solution on clean FTO, vacuum dry for 1 h, and then calcine in a muffle furnace at 450 °C for 2 h.

[0043] (3) 0.06mmol Bi(NO) 3 ·5H 2 O and 0.06 mmol NH 4 VO 3 Dissolve in 400 μL of concentrated nitric acid (70 wt%), add distilled water to 15 mL, put it into the autoclave, put the BiVO obtained after burning in the muffle furnace in step (2) with the conductive side facing down 4 After being hydrothermally heated at 180 °C for 12 h, rinsed with distilled water, calcined in a muffle furnace at 450 °C for 2 h t...

Embodiment 2

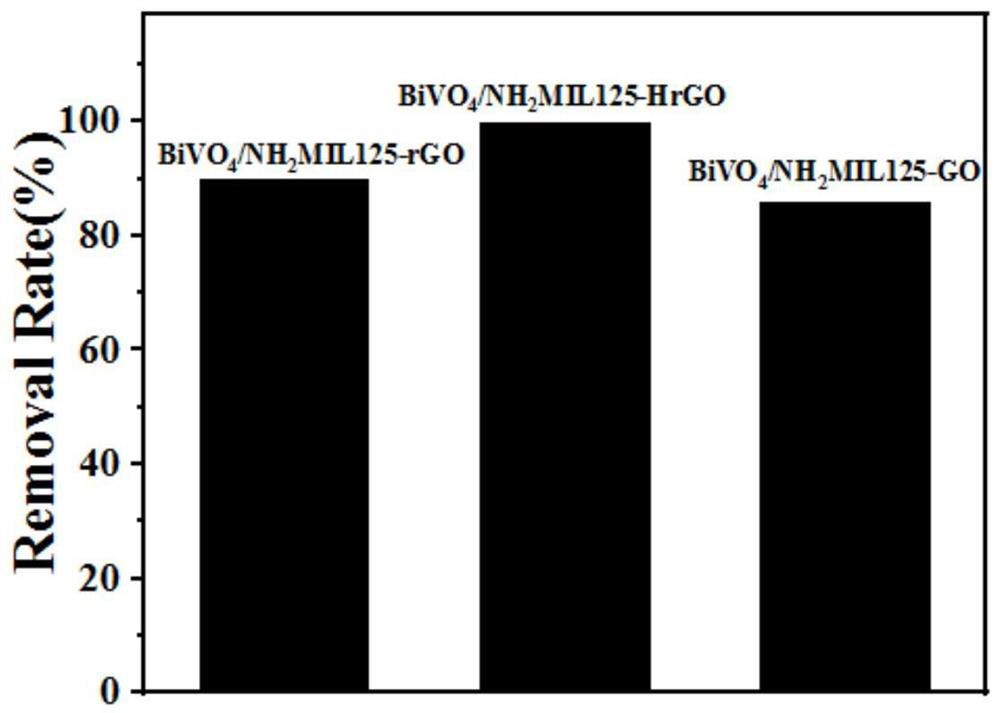

[0047] Preparation of BiVO in this example 4 / NH 2 MIL125-GO and BiVO 4 / NH 2 The method of the MIL125-rGO electrode is basically the same as that in Example 1, except that:

[0048] In step (4), after the two solutions are mixed uniformly, 2 mg GO and 2 mg rGO are added respectively, and the mixture is sonicated for 30 minutes and placed in an autoclave, respectively, and the prepared BiVO 4 electrode, the conductive side was placed in it, and solvothermally at 150 °C for 12 h to obtain BiVO 4 / NH 2 MIL125-GO Electrode and BiVO 4 / NH 2 MIL125-rGO electrode.

[0049] GO and rGO used in this example were prepared by the following methods:

[0050] Graphene oxide (GO) was prepared by chemical oxidation method using the improved Hummers method, using natural graphite powder as raw material; rGO was prepared by chemical synthesis method, and the prepared graphene oxide was pre-reduced with sodium borohydride at 80 °C for 1 h, and then Sulfonation was carried out with an a...

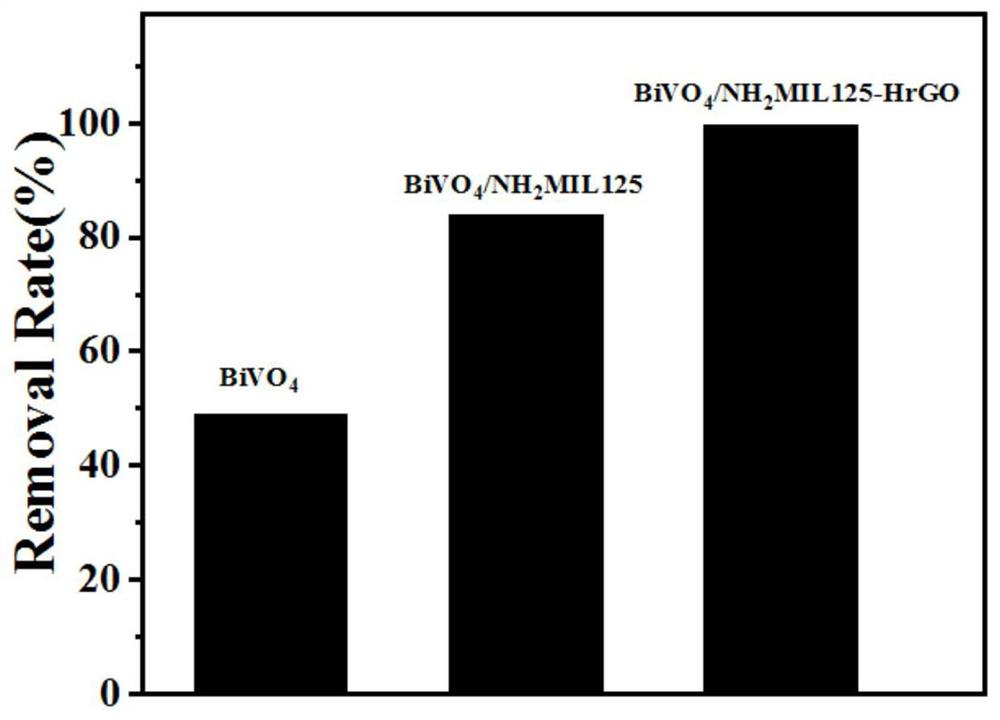

Embodiment 3

[0052] Preparation of BiVO in this example 4 / NH 2 The process of the MIL125 electrode method is basically the same as that in Example 1, except that:

[0053] In step (4), after the two solutions are evenly stirred, they are directly put into the prepared BiVO 4 electrode, the conductive side was placed in it, and solvothermally at 150 °C for 12 h to obtain BiVO 4 / NH 2 MIL125 electrodes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com