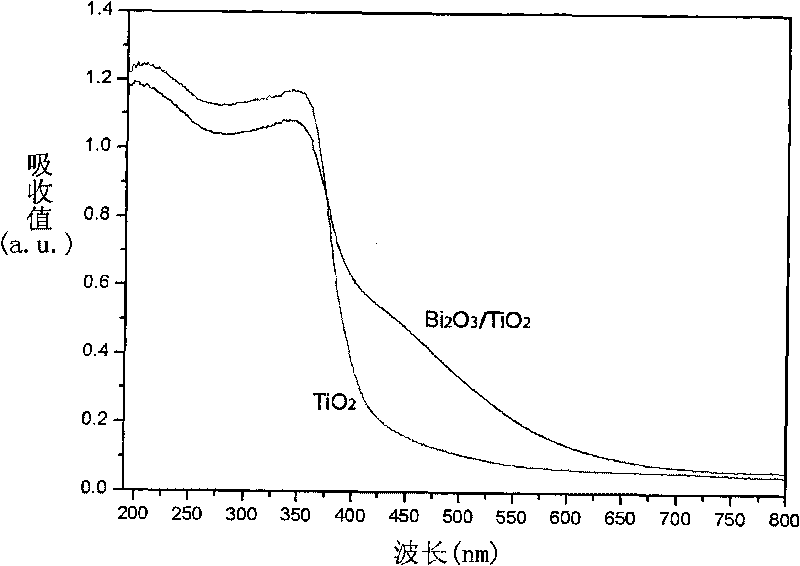

Method for preparing visible light photocatalyst Bi2O3/TiO

A photocatalyst and visible light technology, which is applied in the field of catalytic materials and environmental chemical industry, can solve the problem of high cost and achieve the effect of improving utilization rate, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Add 0.1 gram of cetyltrimethylammonium bromide (CTAB) to 15 mL of absolute ethanol, and ultrasonically dissolve to form a transparent solution A with a CTAB concentration of 0.018 mol / L;

[0022] (2) Add 6 mL of butyl titanate to solution A, and ultrasonically dissolve to form a light yellow solution B with a molar percentage of CTAB and butyl titanate of 1.6%;

[0023] (3) Under stirring, the temperature of solution B was raised to 80° C., 0.154 g of bismuth nitrate pentahydrate was added, and ultrasonically dispersed to form a light yellow sol with a molar percentage of bismuth nitrate pentahydrate and butyl titanate of 1.8%;

[0024] (4) standing at 25°C to form a light yellow gel;

[0025] (5) Aging at 90°C to obtain light yellow small particles;

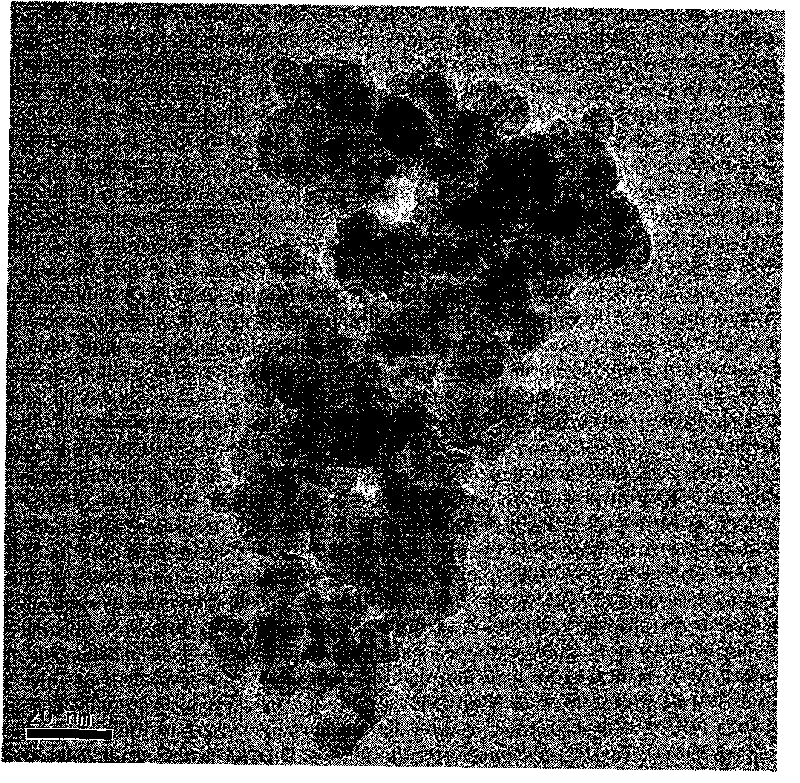

[0026] (6) Warming up to 450°C at room temperature, calcined for 8 hours, and then naturally cooled to room temperature, Bi with visible light catalytic activity was obtained. 2 o 3 / TiO 2 compound semiconductor. ...

Embodiment 2

[0031] (1) 0.06 gram of cetyltrimethylammonium bromide (CTAB) was added to 20 mL of absolute ethanol, and ultrasonically dissolved to form a transparent solution A with a CTAB concentration of 0.008 mol / L;

[0032] (2) 6 mL of butyl titanate was added to solution A, and dissolved by ultrasonic to form a pale yellow transparent solution B with a molar percentage of CTAB and butyl titanate of 1.2%;

[0033] (3) Under stirring, the temperature of solution B was raised to 75°C, 0.09 g of bismuth nitrate pentahydrate was added, and ultrasonically dispersed to form a light yellow sol with a molar percentage of bismuth nitrate pentahydrate and butyl titanate of 1.0%;

[0034] (4) standing at 45°C to form a light yellow gel;

[0035] (5) aging at 80°C to obtain light yellow small particles;

[0036] (6) Warming up to 550°C at room temperature, calcining for 5 hours, and then naturally cooling to room temperature, Bi with visible light catalytic activity was obtained. 2 o 3 / TiO 2 ...

Embodiment 3

[0039] (1) 0.15 g of cetyl trimethyl ammonium bromide (CTAB) was added to 15 mL of absolute ethanol, and dissolved by ultrasonic to form a transparent solution A with a CTAB concentration of 0.028 mol / L;

[0040] (2) 6ml of butyl titanate was added to solution A, and ultrasonically dissolved to form a pale yellow transparent solution B with a molar percentage of CTAB and butyl titanate of 2%;

[0041] (3) under stirring state, solution B is warmed up to 85 ℃, adds 0.22 gram of bismuth nitrate pentahydrate, and ultrasonically disperses to form a pale yellow sol whose molar percentage of bismuth nitrate pentahydrate and butyl titanate is 2.6%;

[0042] (4) Stand at 35°C to form a pale yellow gel;

[0043] (5) Aging at 100°C to obtain light yellow small particles.

[0044] (6) be heated to 500 ℃ at room temperature, calcined for 6.5 hours, then naturally cooled to room temperature to obtain Bi with visible light catalytic activity 2 O 3 / TiO 2 compound semiconductor.

[0045...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com