Carbon nano-based fiber as well as preparation method and application thereof

A carbon nano, carbon nanotube technology, applied in the chemical characteristics of fibers, conductive/antistatic filament manufacturing, textiles and papermaking, etc., can solve the problem of difficulty in preparing pure carbon nanotube fibers, threats to operator safety, Structural damage and other problems, to achieve the effect of less harsh experimental conditions, safe operation and lower production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] An aspect of the embodiments of the present invention provides a method for preparing carbon nano-based fibers, which includes:

[0028] Provide a carbon nanotube dispersion comprising carbon nanotubes and a dispersant, wherein the content of carbon nanotubes in the carbon nanotube dispersion is 1.01 to 3 wt %;

[0029] Using the carbon nanotube dispersion as a spinning solution, using wet spinning technology, injecting the spinning solution into a coagulation bath to obtain carbon nano-based fibers, wherein the coagulation bath includes organic solvents and / or organic A mixed solution of solvent and water, the organic solvent includes any one or a combination of two or more of acetone, ethanol, isopropanol, ethylene glycol and 1,2-propanediol, the organic solvent and water in the coagulation bath The volume ratio is 1:0~1:8.

[0030] The present invention can adjust the structure and performance of the carbon nano-based fiber by adjusting the types of coagulation bath...

Embodiment 1

[0044] In this example, the carbon nanotube powder with a length of 1 μm can be dispersed in deionized water through a dispersant such as sodium cholate. The mass ratio of sodium cholate to carbon nanotubes is 1:1. After massaging for 15 minutes, the pressure was 50 MPa to obtain a carbon nanotube dispersion, and the carbon nanotube content in the obtained carbon nanotube dispersion was 1.01 wt%.

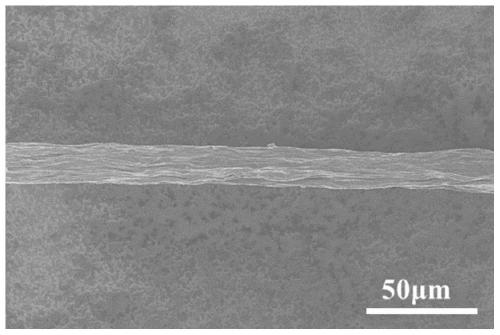

[0045] The prepared carbon nanotube dispersion was passed through a 50 μm spinneret hole and extruded into an isopropanol coagulation bath at 8 μL / s. The gel fiber is obtained through solution exchange, and the gel fiber is taken out and soaked in water for several hours, then taken out, and then dried naturally under tension. After testing, the electrical conductivity of the prepared carbon nano-based fibers (i.e. carbon nanotube fibers) was 5.0×10 3 S / cm, the tensile strength is 200MPa.

[0046] see figure 1 The physical figure of the carbon nanotube fiber continuously prepared...

Embodiment 2

[0048] In this example, the carbon nanotube powder with a length of 50 μm is dispersed in deionized water through PVP. The mass ratio of PVP to carbon nanotube powder is 0.1:1. 50 MPa to obtain a carbon nanotube dispersion, and the carbon nanotube content in the obtained carbon nanotube dispersion is 2wt%.

[0049] The prepared carbon nanotube dispersion was passed through a 200 μm spinneret hole, and extruded into an ethylene glycol coagulation bath at 2 μL / s to obtain gel fibers through solution exchange, and the gel fibers were taken out and soaked in water for several hours , and then take it out, add tension to dry naturally, and take out a part of the dried fiber for testing.

[0050] The electron micrograph of the carbon nanotube fiber that present embodiment obtains please refer to Figure 4a-Figure 4c .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com