Water-resistant and salt-resistant anticorrosive paint

An anti-corrosion coating and salt-resistant technology, applied in anti-corrosion coatings, coatings, etc., can solve problems such as high cost, poor anti-corrosion performance, and poor antibacterial effect, and achieve the effects of reducing corrosion, improving anti-corrosion performance, and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

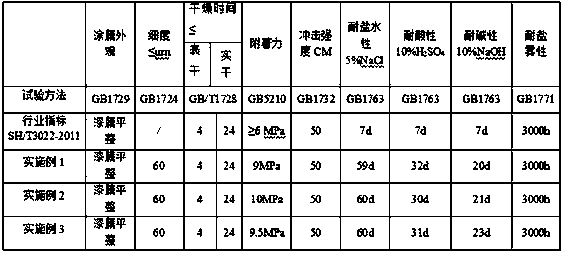

Examples

Embodiment 1

[0018] The invention discloses a water-salt-resistant anti-corrosion coating, which comprises a primer coating and a surface coating. The surface coating is composed of A component and B component, and A component is composed of the following parts by mass: 35 parts of hydroxyacrylic acid, 0.3 parts of emulsified methyl silicone oil, 0.3 parts of silicone leveling agent, 15 parts of hydrophobic fumed silica, 30 parts of fibrous talcum powder, 15 parts of nano-silicon carbide, 5 parts of polyester resin, 0.8 parts of hindered amine, ultraviolet light Absorber UV-P 0.8 parts, butyl acetate 2 parts, organosilane coupling agent KH-550 0.5 parts; B component consists of the following parts by mass: polyamide resin 70 parts, polyketone 10 parts, paraformaldehyde 12 parts parts, wherein the mass ratio of component A to component B is 3:1.

[0019] The primer is composed of component C and component D, and component C is composed of the following mass fractions: 35 parts of bisphenol ...

Embodiment 2

[0021] The invention discloses a water-salt-resistant anti-corrosion coating, which comprises a primer and a surface coating, the surface coating is composed of A component and B component, and the A component is composed of the following parts by mass: 40 parts of hydroxyacrylic acid, 0.5 parts of polyether defoamer, 0.5 parts of fluorocarbon leveling agent, 20 parts of hydrophobic fumed silica, 28 parts of fibrous talcum powder, 15 parts of nano-silicon carbide, 5 parts of polyester resin, hindered amine 1 part, 1 part of ultraviolet absorber UV-O, 3 parts of butyl acetate, 0.5 part of organic silane coupling agent KH-560; component B consists of the following parts by mass: polyamide resin 75 parts, polyketone 15 parts, 10 parts of paraformaldehyde, wherein the mass ratio of component A to component B is 3.5:1.

[0022] The primer is composed of components C and D, and component C is composed of the following mass fractions: 38 parts of bisphenol A epoxy resin, 0.6 parts of...

Embodiment 3

[0024]A water-salt-resistant anti-corrosion coating, including a primer and a top coat, the top coat is composed of A component and B component, and A component is composed of the following parts by mass: 45 parts of hydroxyacrylic acid, polysiloxane 0.6 parts of defoamer, 0.6 parts of acrylate leveling agent, 25 parts of hydrophobic fumed silica, 25 parts of fibrous talcum powder, 10 parts of nano-silicon carbide, 5 parts of polyester resin, 0.9 parts of hindered amine, ultraviolet absorber 0.9 parts of UV-9, 4 parts of butyl acetate, 0.6 parts of a mixture of organosilane coupling agent KH-550 and organosilane coupling agent KH-560; component B consists of the following parts by mass: 80 parts of polyamide resin , 20 parts of polyketones, and 8 parts of paraformaldehyde, wherein the mass ratio of component A to component B is 4:1.

[0025] The primer is composed of components C and D, and component C is composed of the following mass fractions: 40 parts of bisphenol A epoxy ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com