Preparation method for preparing two-dimensional layered transition metal sulfide

A transition metal, two-dimensional layered technology, applied in the field of materials, can solve the problems of large-scale constraints, high prices, and low yields of materials, and achieve the effects of reduced control difficulty, low prices, and high dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

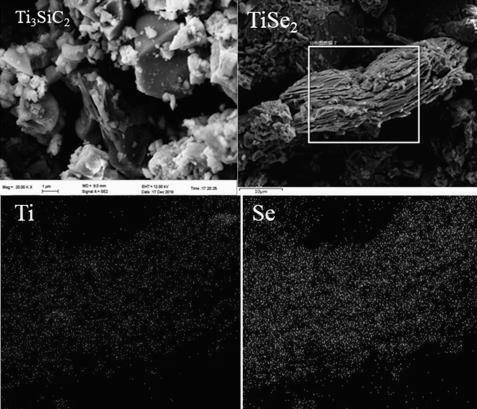

[0024] 5g 400 mesh Ti 3 SiC 2 The max phase ceramic powder is placed in the 1# alumina ceramic ark crucible, and then 5g of elemental Se is placed in the 2# ark crucible, and then placed in the furnace tube of a tube furnace at 1600 degrees, at a speed of 5 degrees per minute Raise the temperature to 900°C for 5 hours and then cool down slowly. During the cooling process, keep the cooling process at 5°C per minute. After cooling to room temperature, take the reactants in the 1# ark and ball mill them to 400 mesh. It needs to be done in the protective atmosphere of Ar gas. SEM characterization of all products as figure 1 Relatively obvious organ-like TMDCS-TiSe 2。

example 2

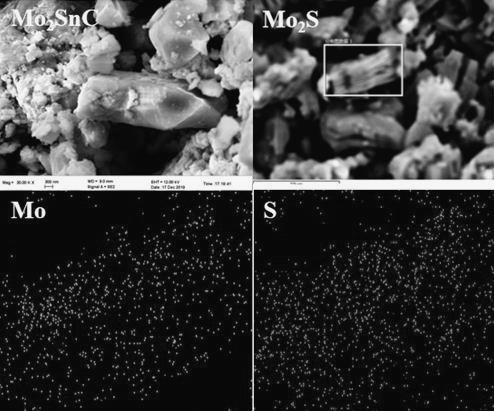

[0026] Place 5g of 400-mesh Mo2AlC max phase ceramic powder in an alumina ceramic ark crucible, pass through such as argon and H 2 The mixed gas of S is heated up to 800°C at a heating rate of 5 degrees per minute and kept for 5 hours, and then slowly cooled to room temperature. During the cooling process, argon protection must be introduced at the same time. The reacted powder can be obtained after ball milling in a stainless steel ball mill tank. Organ-shaped TMDCS-Mo 2 SEM image of S powder and its characterization figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com