Sulfanlyl glyceryl glucoside, preparation method thereof and drilling fluid

A technology of sulfonamidoglycerol-based sugar and oil-based sugar is applied in the field of drilling fluid, which can solve the problem that the lubricating performance requirements of high-density drilling fluid cannot be well met, the lubricating performance of high-density drilling fluid is little improved, and the lubricating effect of drilling fluid can be solved. There is no obvious improvement and other problems, and the effects of good inhibition performance and compatibility performance, favorable for promotion and application, good economic and social benefits are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Add 102g of glyceryl glycoside, 20g of propylene oxide, 45g of thionyl chloride, 30g of epichlorohydrin and 4g of hydrochloric acid into a four-necked flask equipped with a condensing reflux and stirring device, and control the stirring speed at 900r / min. React at a temperature of 2 hours to obtain glyceryl glycoside polyether;

[0074] Add 70g of ethylenediamine to the above glyceryl glycoside polyether, control the stirring speed to 900r / min, and react at a temperature of 70°C under normal pressure for 2 hours to obtain polyetheraminoglyceryl glycoside;

[0075] Add 150g of sulfonated castor oil to the polyetheraminoglyceryl glycoside, stir well, then add sodium hydroxide to adjust the pH of the reaction solution to 9, and react at 60°C for 3 hours at a stirring speed of 900r / min , to obtain bright red transparent viscous sulfamoglyceryl glycoside.

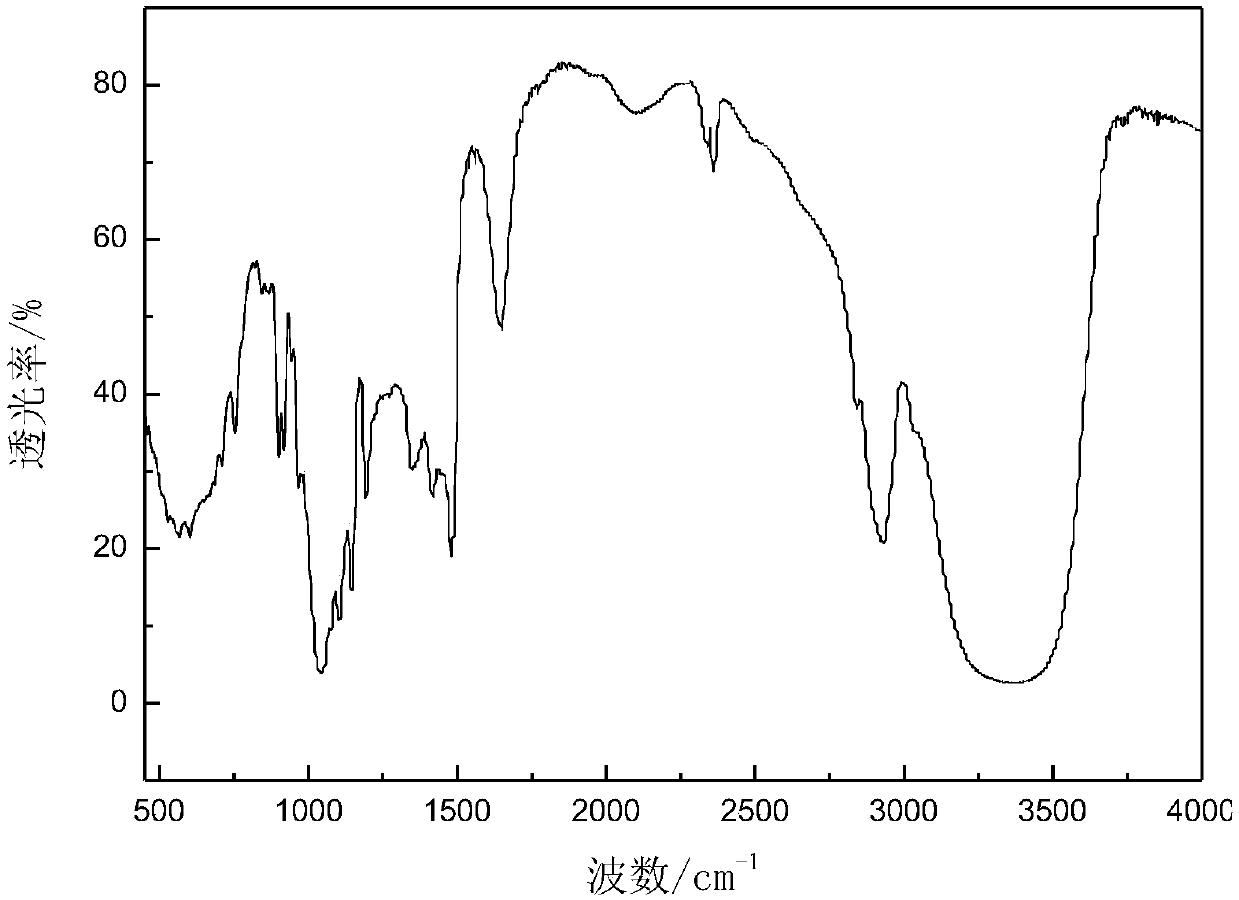

[0076] The product prepared in Example 1 of the present invention is detected by infrared spectrum, and the infrared s...

Embodiment 2

[0081] Add 102g of glyceryl glucoside, 25g of butylene oxide, 50g of sulfuryl chloride, 35g of epoxychlorobutane and 5g of sulfuric acid into a four-necked flask with a condensing reflux and stirring device, and control the stirring speed at 1000r / min, at 100°C React at a temperature of 3 hours to obtain glyceryl glycoside polyether;

[0082] Add 80 g of diethylenetriamine to the above-mentioned glyceryl glycoside polyether, control the stirring speed to 1000 r / min, and react at a temperature of 80° C. under normal pressure for 3 hours to obtain polyether amino glyceryl glycoside;

[0083] Add 160g of sulfonated castor oil to the polyetheraminoglyceryl glycoside, stir well, then add sodium hydroxide to adjust the pH of the reaction solution to 10, and react at 70°C for 4 hours at a stirring speed of 1000r / min , to obtain bright red transparent viscous sulfamoglyceryl glycoside.

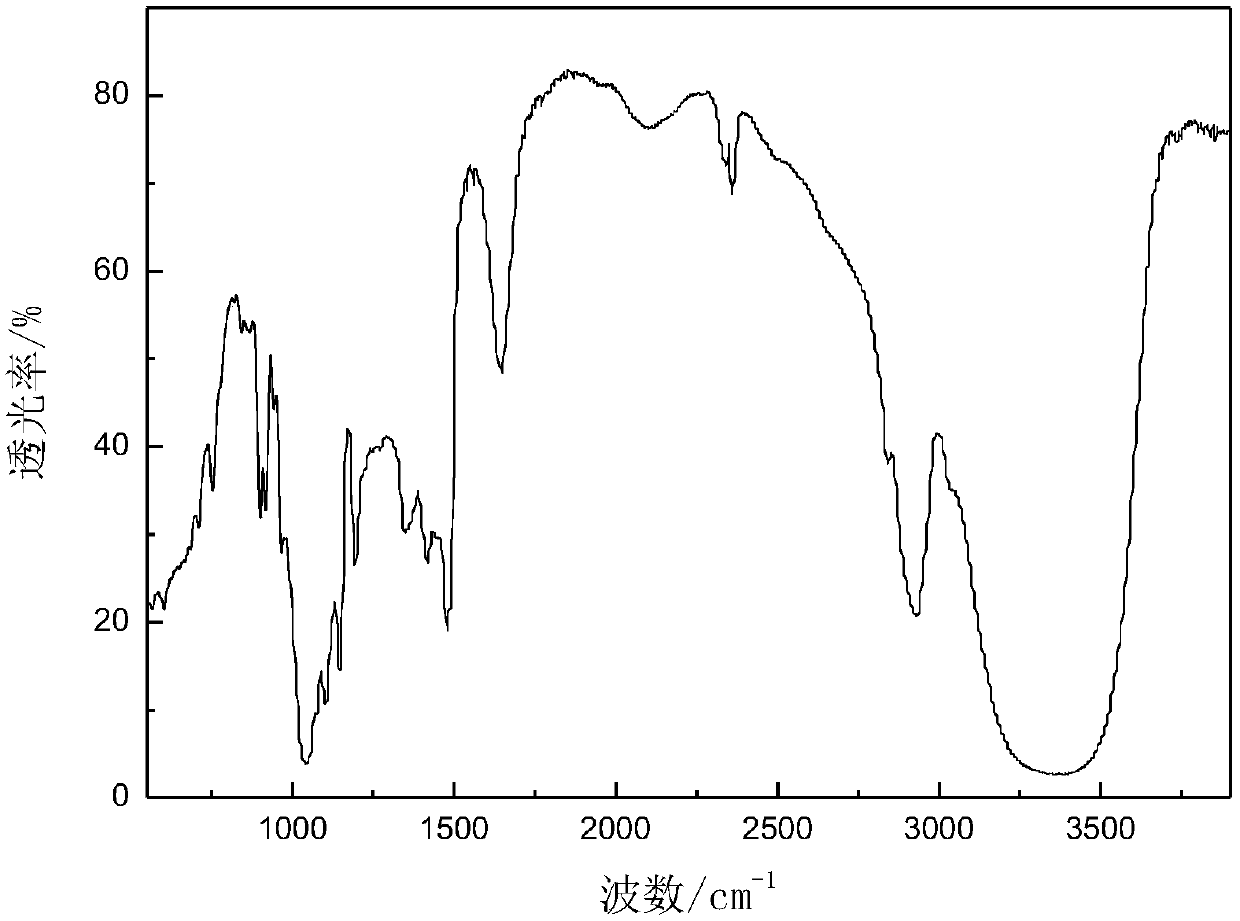

[0084] The product prepared in Example 2 of the present invention is detected by infrared spectru...

Embodiment 3

[0089] Add 102g glyceryl glucoside, 30g pentylene oxide, 55g phosphorus trichloride, 40g epoxychloropentane and 6g citric acid into a four-necked flask with condensation reflux and stirring device, control the stirring speed to 1100r / min, React at a temperature of 110° C. for 4 hours to obtain glyceryl glycoside;

[0090] Add 90g of triethylenetetramine to the above glyceryl glycoside polyether, control the stirring speed to 1100r / min, and react at a temperature of 90°C under normal pressure for 4 hours to obtain polyether aminoglyceryl glycoside;

[0091] Add 170g of sulfonated castor oil to the polyetheraminoglyceryl glycoside, stir well, then add sodium hydroxide to adjust the pH of the reaction solution to 11, and react at 80°C for 5 hours at a stirring speed of 1100r / min , to obtain bright red transparent viscous sulfamoglyceryl glycoside.

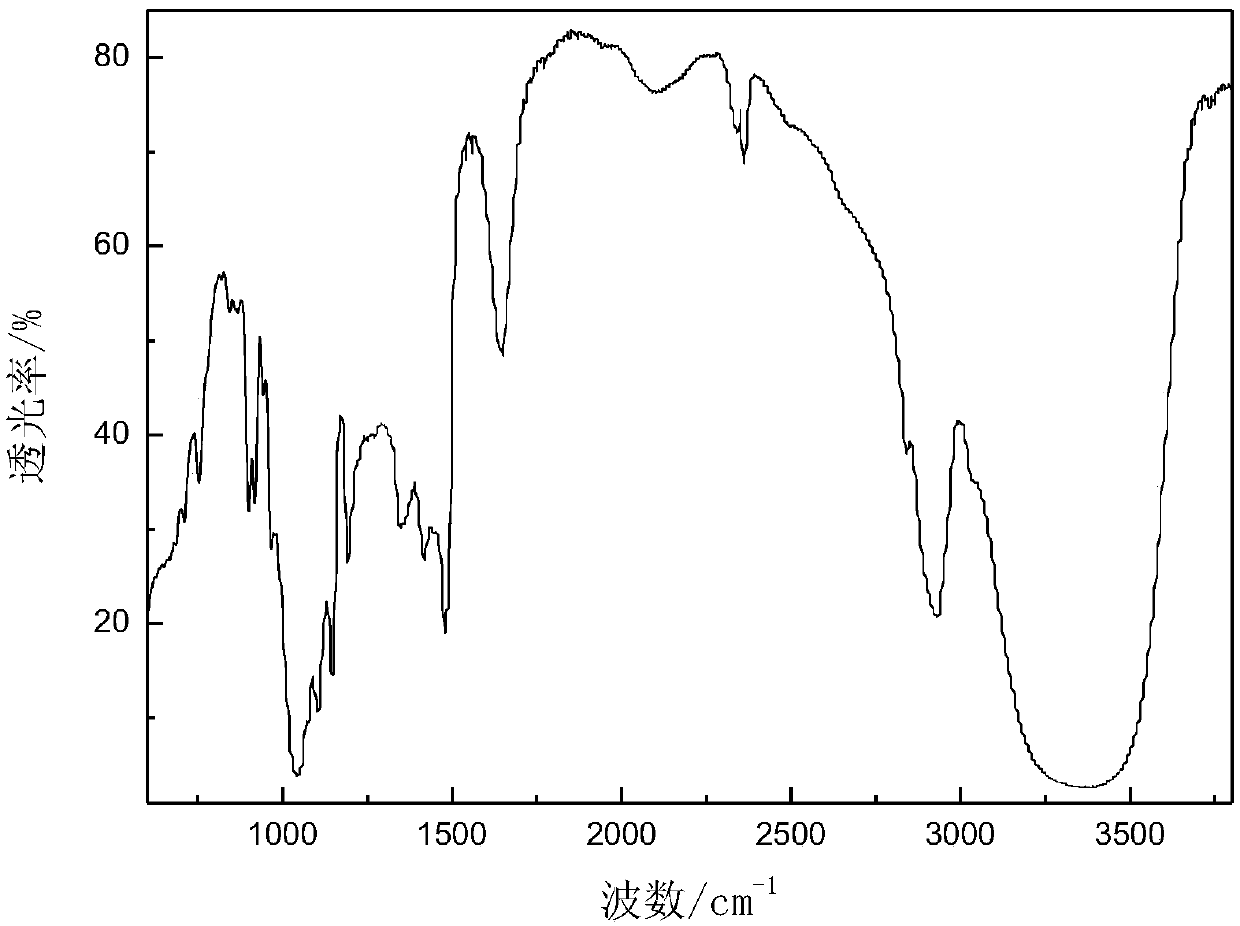

[0092] The product prepared in Example 3 of the present invention is detected by infrared spectrum, and the infrared spectrum is as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com