Green and efficient incineration method for hazardous waste in rotary kiln based on oxygen enriched air supply in secondary combustion chamber

A secondary combustion chamber, oxygen-enriched air supply technology, applied in the direction of combustion method, combustion type, indirect carbon dioxide emission reduction, etc., can solve the problems of difficult accurate control of denitrification reaction temperature, high cost, increased operating costs, etc., to achieve The effect of inhibiting the synthesis of dioxins, reducing the total amount of flue gas, and increasing the effective height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

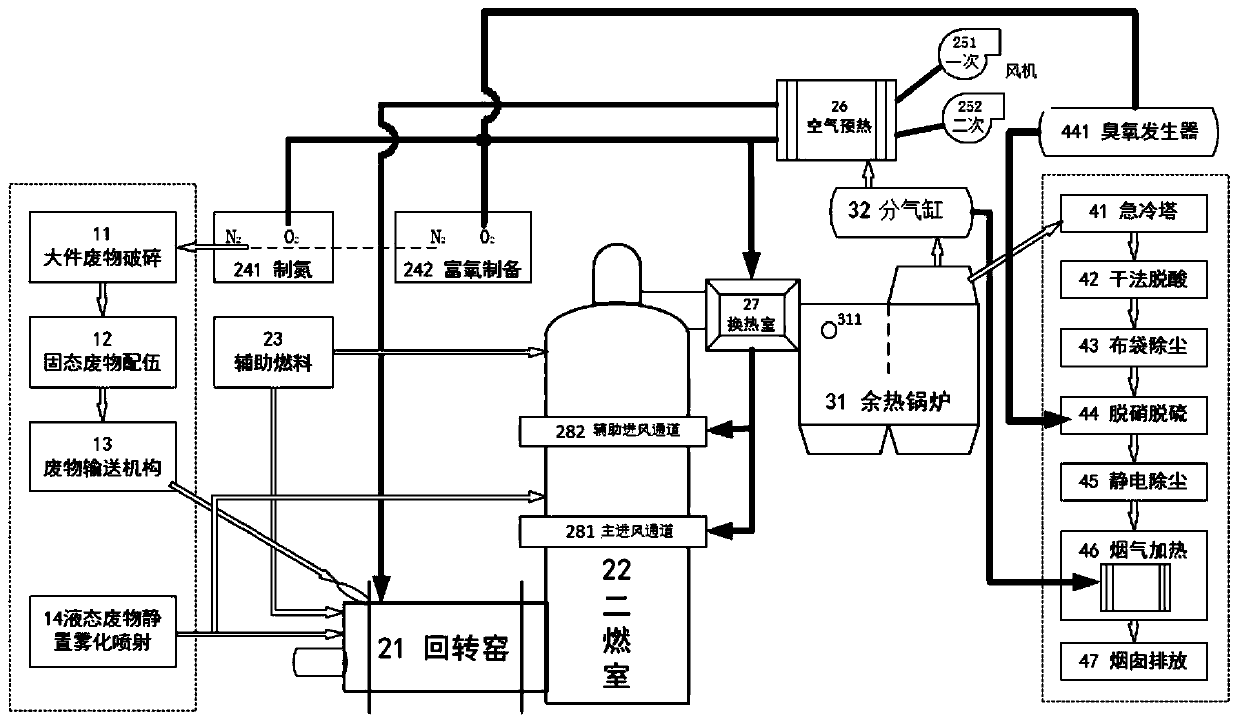

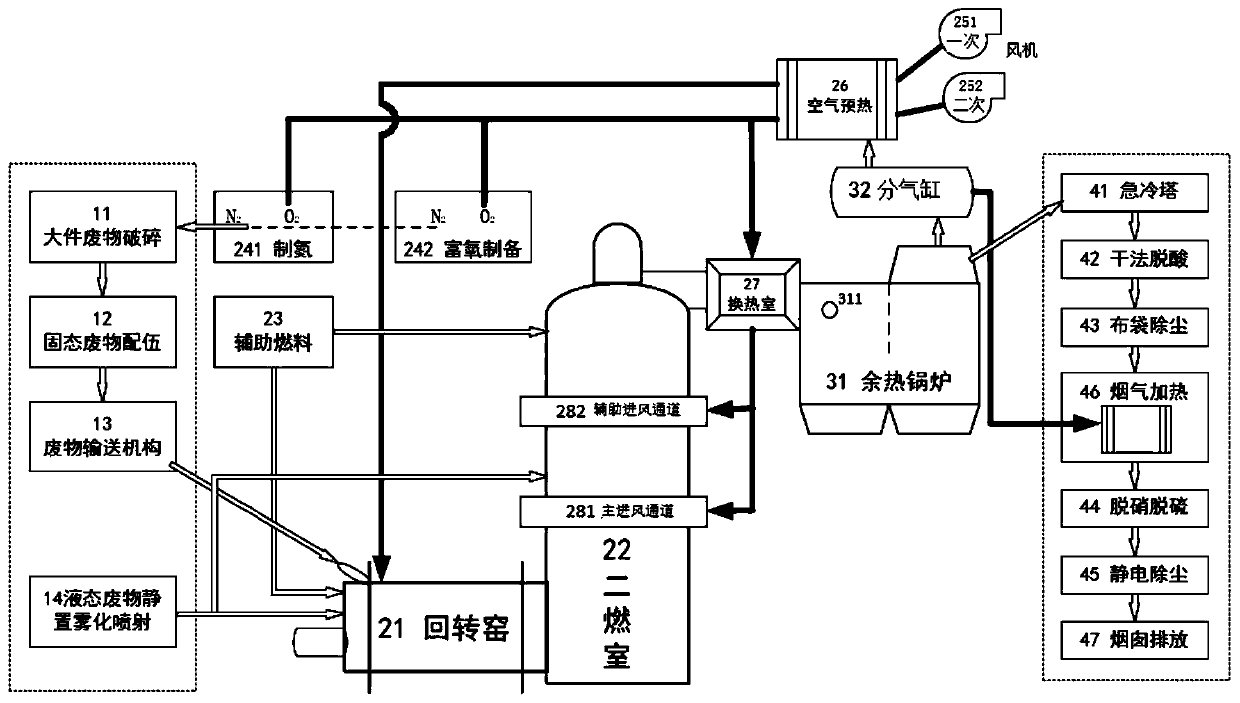

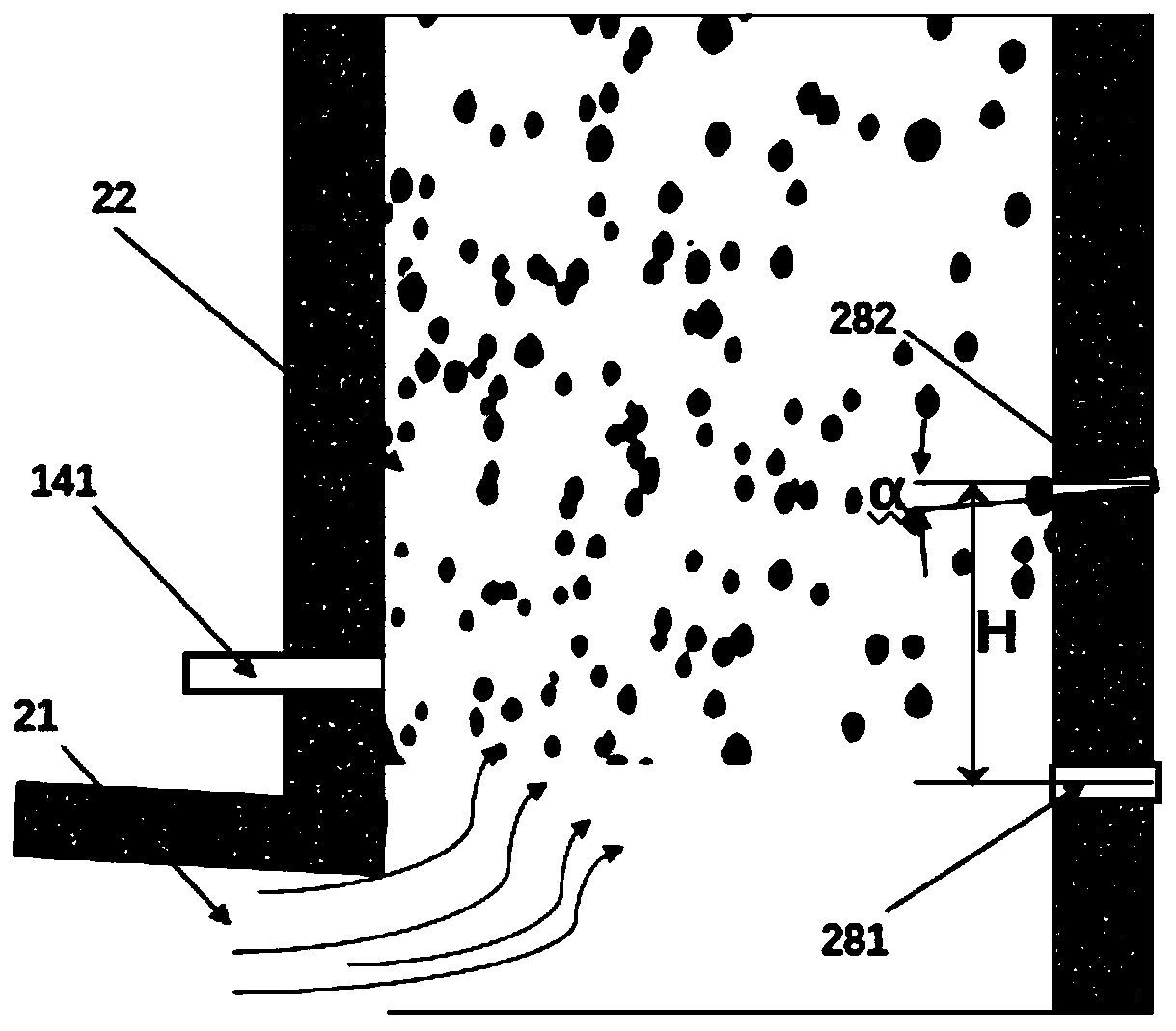

[0033] Such as Figure 1-4 As shown, the green and efficient hazardous waste rotary kiln incineration treatment method based on the oxygen-enriched air supply in the secondary combustion chamber includes: pretreatment and feeding, incineration in the secondary combustion chamber of the rotary kiln, waste heat utilization and flue gas purification.

[0034] (1) Pretreatment and feeding.

[0035] The pretreatment and feeding system includes a solid waste crushing device 11 , a solid waste compatibility device 12 , a waste conveying mechanism 13 , and a liquid waste filtering and standing and atomizing spraying device 14 . The solid waste passes through the solid waste crushing device 11, the solid waste compatibility device 12 and the waste conveying mechanism 13 in turn. The solid waste crushing device 11 crushes large solid waste into pieces, and the crushed solid waste passes through the solid waste compatibility device 12 and the semi-solid waste Compatible and mixed evenly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com