Portable waste incineration device

A waste incineration, portable technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems that are difficult to incorporate into the centralized incineration and disposal system of urban waste, and achieve low thermal burning rate of slag, high incineration temperature, and low harmful components Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail through the following examples, which are illustrative rather than restrictive, and cannot limit the protection scope of the present invention.

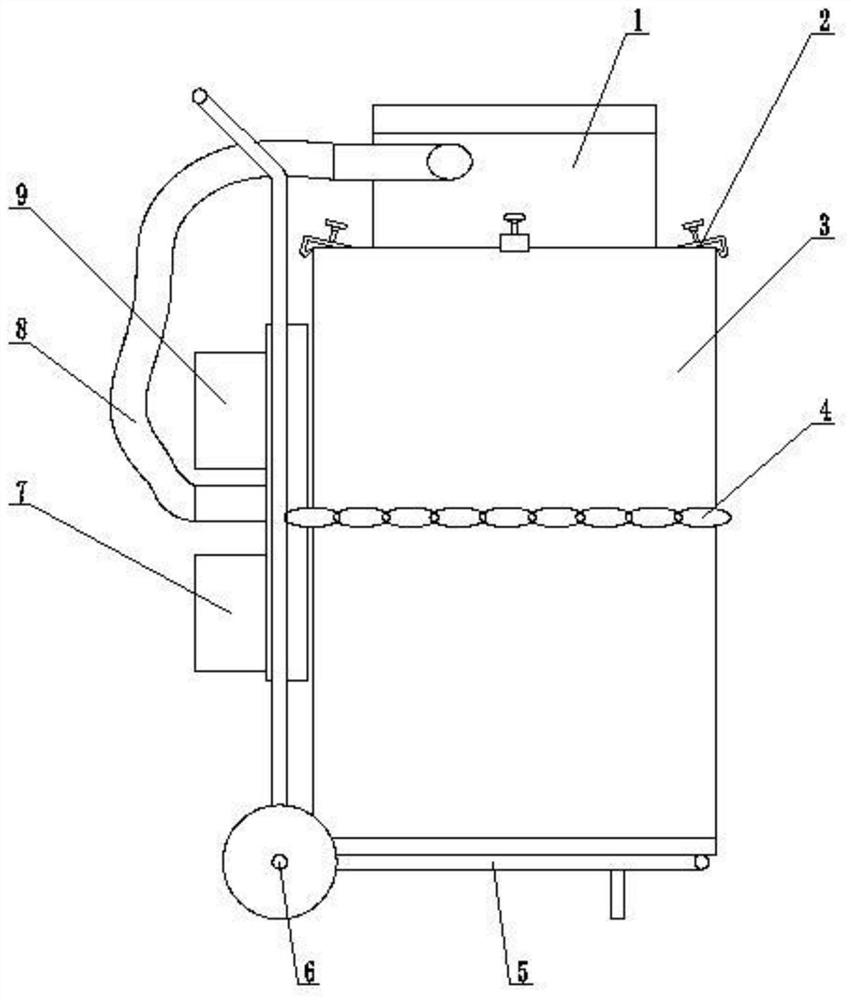

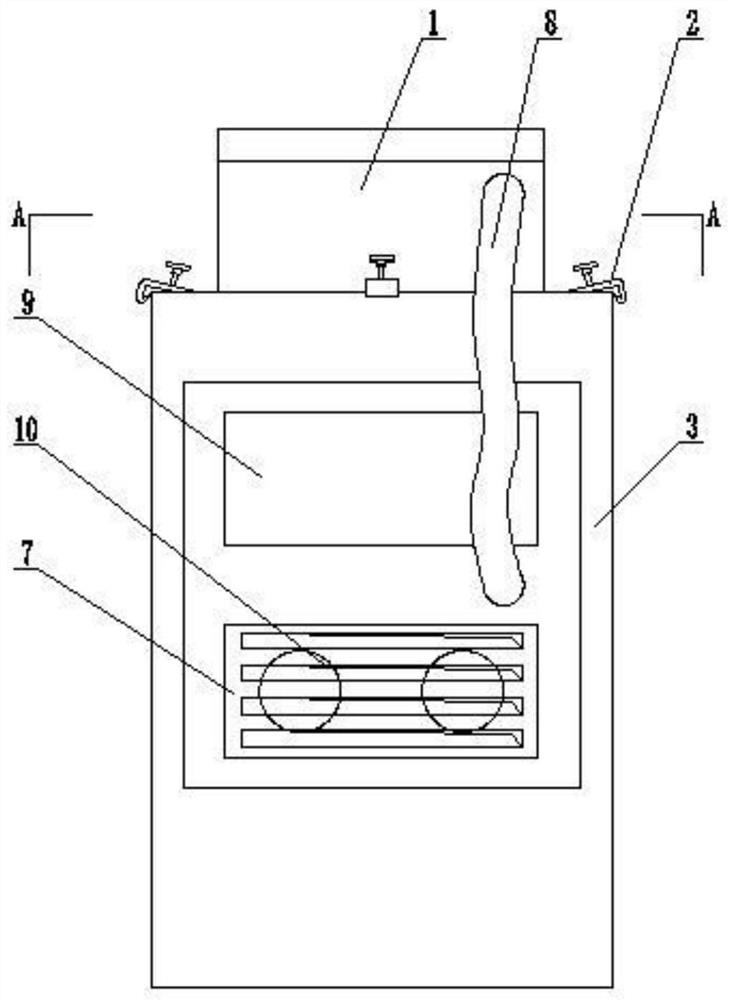

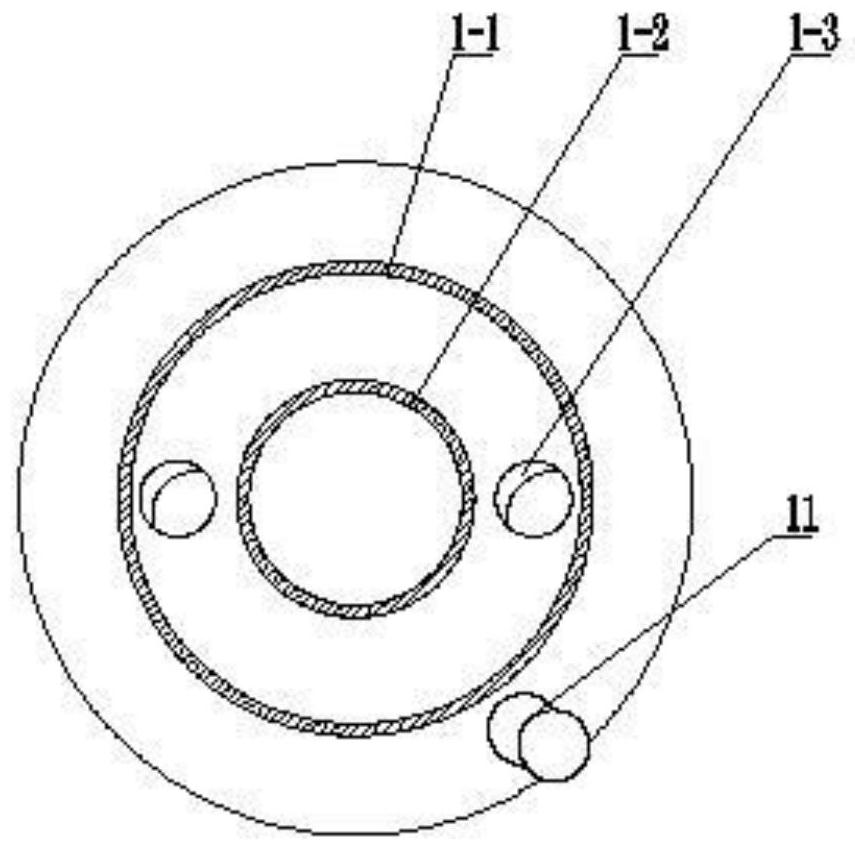

[0017] A portable garbage incineration device. The innovation of the present invention is that it includes a mobile bracket 5, an incineration barrel 3 and a fire puller. The mobile bracket and the incineration barrel are movably installed to drive the incineration barrel to move. The interior of the incineration barrel is hollowed out Combustion chamber, this incinerator barrel outer wall is shaped on the fire-drawing hole 11 that is communicated with combustion chamber, can accommodate fire-drawing stick to stretch into in described fire-drawing hole, and fire-drawing stick can stir the rubbish that is placed in the combustion chamber.

[0018] In this embodiment, the volume of the combustion chamber in the incinerator should not be less than 200L, so as to improve its capacit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com