High-boiling residue, waste liquid and waste salt co-processing system

A co-processing, high-boiling technology, applied in the combustion method, combustion type, incinerator, etc., can solve the problems of equipment sticking, difficult to control the content of residual organic components in net salt, and difficult to operate continuously and stably, to prevent salinity. The effect of molten sticky walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

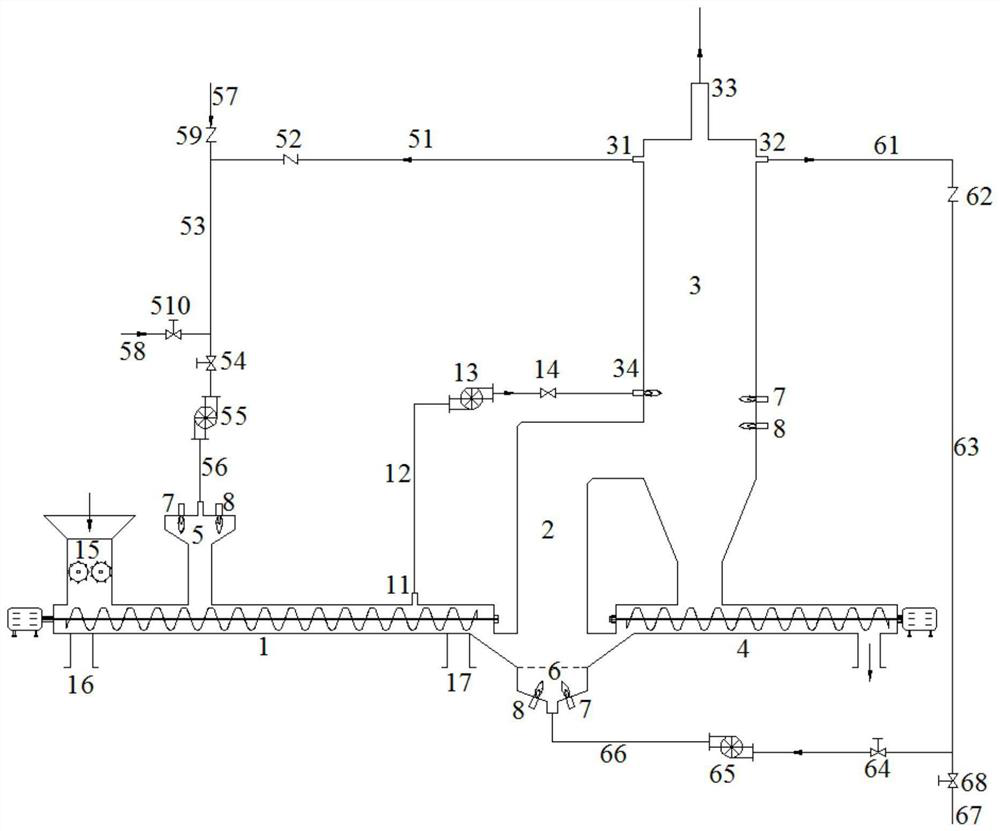

[0024] A co-processing system for high boilers, waste liquid, and waste salt proposed in this embodiment includes a pyrolysis gasification bed 1 for converting organic matter in high boilers, waste liquid, and waste salt into combustible gas. Fluidized bed incinerator 2 for removing high boilers, waste liquid, and residual organic matter in waste salt, used to burn out the combustible gas produced by the pyrolysis gasification bed 1 and fluidized bed incinerator 2 for unburned Secondary combustion chamber 3 with all organic fumes;

[0025] The pyrolysis gasification bed 1 is provided with a feed port for adding high boilers and waste salt, and the discharge port of the pyrolysis gasification bed 1 is connected with the feed port of the fluidized bed incinerator 2, The pyrolysis gasification bed 1 is provided with a combustible gas outlet 11 connected to the second combustion chamber 3; the discharge port of the fluidized bed incinerator 2 is connected to a discharge conveyor 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com