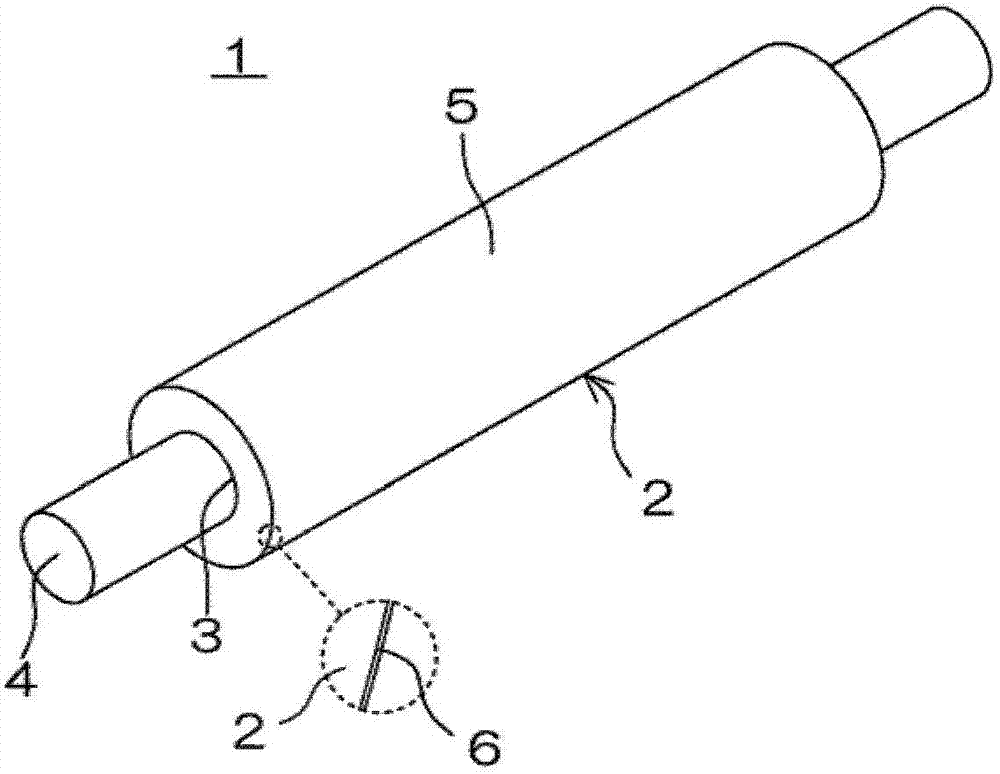

Developing roller

一种显影辊、外周面的技术,应用在显影辊领域,能够解决易产生摩擦热、图像不良、无法可靠地防止调色剂熔融粘着等问题,达到延缓熔融粘着、防止熔融粘着的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0130] (Preparation of rubber composition)

[0131] As the base rubber, 10 parts by mass of SBR (JSR1502 manufactured by JSR Corporation), 20 parts by mass of ECO [Epichlomer (registered trademark) D manufactured by Daiso Corporation, ethylene oxide content 61 mol %], and CR [ Shoprene (registered trademark) WRT] manufactured by Showa Denko Co., Ltd. was blended in 70 parts by mass. The proportion of SBR in the total amount of base rubber was 10% by mass.

[0132] 100 parts by mass of the above-mentioned base rubber in total was kneaded with a Banbury mixer, while adding and kneading components other than the cross-linking component among the components shown in Table 1 below, and finally adding the cross-linking component, and further Kneading was carried out to prepare a rubber composition.

[0133] Table 1

[0134] Element

parts by mass

Ethylenethiourea

0.5

5% oil-extended sulfur

1.2

accelerator DT

0.43

accele...

Embodiment 2

[0151] A developing roller was produced in the same manner as in Example 1 except that SBR was 20 parts by mass, ECO was 20 parts by mass, and CR was 60 parts by mass. The proportion of SBR in the total amount of base rubber was 20% by mass. In addition, the surface roughness Ra of the outer peripheral surface of the roller main body was 1.32 μm as in Example 1.

Embodiment 3

[0153] A developing roller was produced in the same manner as in Example 1 except that SBR was 30 parts by mass, ECO was 20 parts by mass, and CR was 50 parts by mass. The proportion of SBR in the total amount of base rubber was 30% by mass. In addition, the surface roughness Ra of the outer peripheral surface of the roller main body was 1.32 μm as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com