Acrylic fiber treatment agent and its application

A technology of acrylic fiber and treatment agent, applied in the direction of fiber treatment, fiber type, fiber chemical characteristics, etc., can solve the problems of broken wire operability, sintering furnace damage, filament entanglement, etc., to prevent stable operability, prevent melting sticky effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

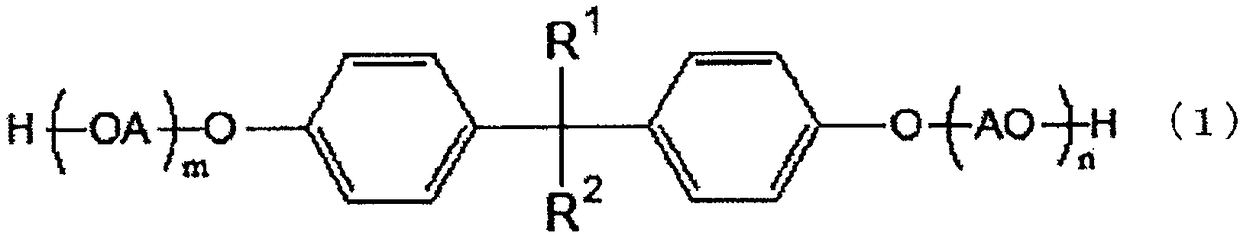

Method used

Image

Examples

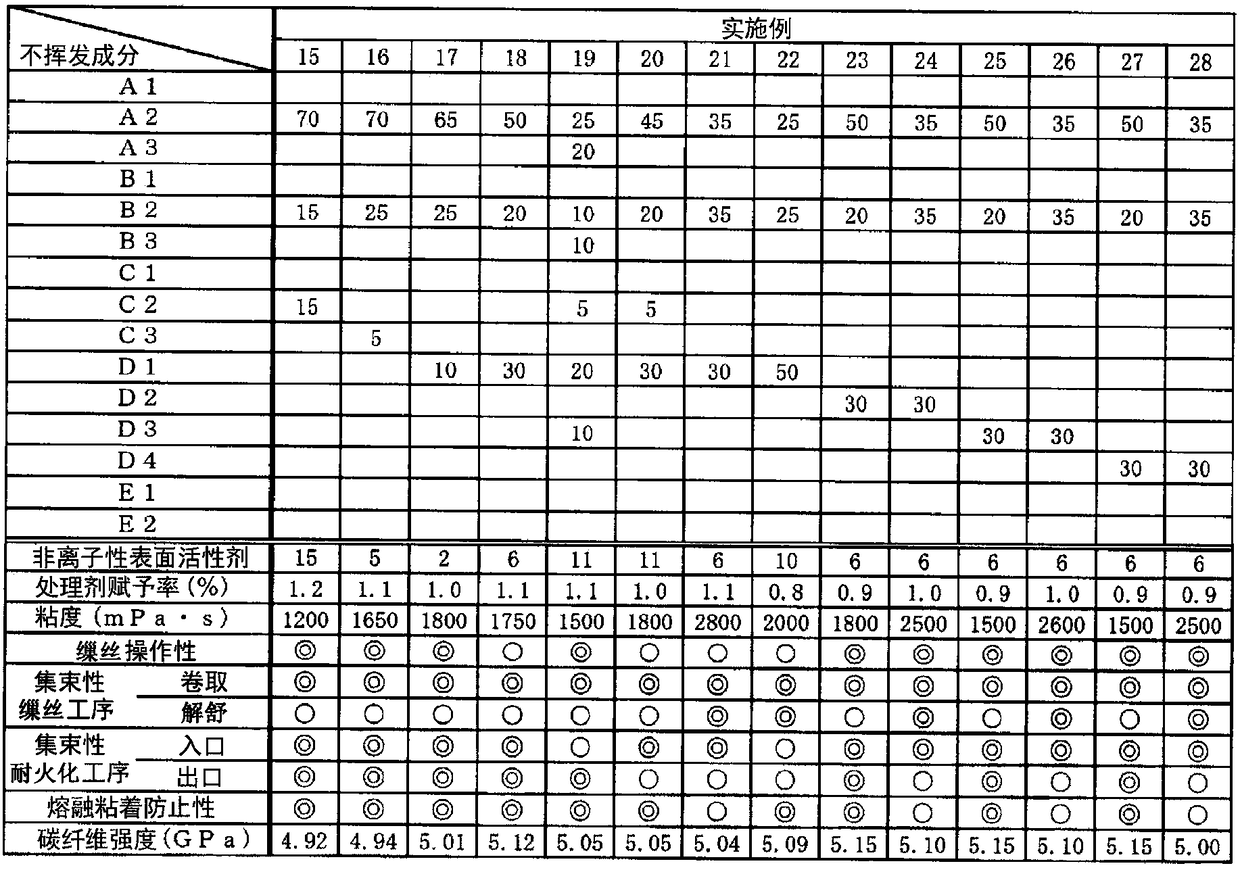

Embodiment 1~28、 comparative example 1~13

[0147] Water-based emulsification using the following compounds A1-A3, polyether compounds B1-B3, nonionic surfactants C1-C3, modified silicone D1-D4 prepared above, and ester-based compounds E1-E2 and water were mixed and stirred according to the non-volatile components shown in Tables 1 to 3 to prepare acrylic fiber treatment agents whose non-volatile components accounted for 20% by weight in the treatment agent. In addition, the numerical value in a table shows the weight ratio of each component in the non-volatile content of a processing agent. For example, the numerical values of the compounds A1 to A3 in the table represent the weight ratios of the compounds A1 to A3 in the non-volatile components of the treatment agent. In addition, the numerical value of the "nonionic surfactant" of Tables 1-3 shows the weight ratio (weight%) which a nonionic surfactant (total amount) occupies in a nonvolatile component.

[0148] Next, the prepared treatment agents were further dilu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com