5G antenna flexible insulation cooling fin and preparation process thereof

A preparation process and technology for heat sinks, applied in antennas, antenna parts, heat exchange materials, etc., can solve the problems that heat sinks cannot meet insulation requirements, 5G mobile phone requirements, and low dielectric performance requirements. Achieve high heat dissipation requirements, easy operation, and low dielectric loss values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

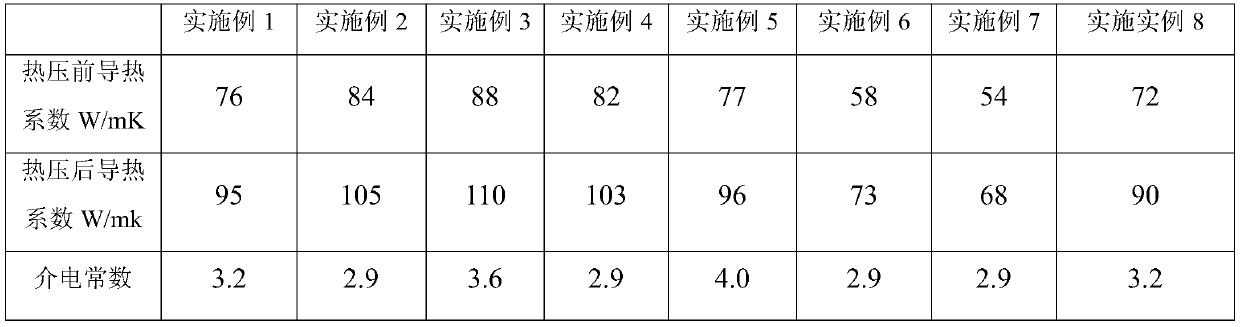

Examples

preparation example Construction

[0030] The preparation process of the 5G antenna flexible insulating heat sink, the preparation process of the heat sink includes the following steps:

[0031] In the first step, put component A into a planetary grinder for grinding and pre-dispersion, control the rotation speed of the planetary grinder to 1-100r / min, the temperature to 10-25°C, the stirring time to 20min, and then control the temperature to 60 -75°C, the stirring reaction time is 3-4h, and the slurry A is obtained;

[0032] In the second step, add component B to the slurry A for mixing and pre-dispersion, control the low gear of the planetary mill at 1-10RPM / min, the high gear at 2000-5000RPM / min, control the temperature at 10-25°C, and stir for 0.5 -3 hours, obtain slurry B;

[0033] The third step is to add dispersant A to the slurry B to mix and pre-disperse, control the low gear of the planetary mill at 0-10RPM / min, the high gear at 1000-5000RPM / min, control the temperature at 10-25°C, and mix and pre-di...

Embodiment 1

[0043] Component A accounts for 60%: high thermal conductivity insulating powder accounts for 50%, of which alumina (7μm): silicon carbide (20μm): aluminum nitride (5μm) = 3:5:2; solvent A (toluene: acetic acid Ethyl ester mass ratio is 2:8) accounted for 49%; dispersant B accounted for 1%;

[0044] Component B accounts for 39%; MPi resin accounts for 50%, solvent B (toluene:ethyl acetate mass ratio is 2:8) accounts for 50%;

[0045] Dispersant A accounted for 1%.

Embodiment 2

[0047] Component A accounts for 60%: high thermal conductivity insulating powder accounts for 50%, of which alumina (7μm): silicon carbide (20μm): boron nitride (5μm) = 3:5:2; solvent A (toluene: acetic acid Ethyl ester mass ratio is 2:8) accounted for 49%; dispersant B accounted for 1%;

[0048] Component B accounts for 39%; LCP resin accounts for 50%, solvent B (toluene:ethyl acetate mass ratio is 2:8) accounts for 50%;

[0049] Dispersant A accounted for 1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com