PC/ABS alloy resistant to damp-heat aging and preparation method thereof

A damp-heat-resistant and ABS resin technology is applied in the field of damp-heat-resistant PC/ABS alloy and its preparation, which can solve the problems of low damp-heat aging resistance, material performance deterioration, material degradation, etc. System thermal expansion coefficient, effect of improving hydrolysis resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

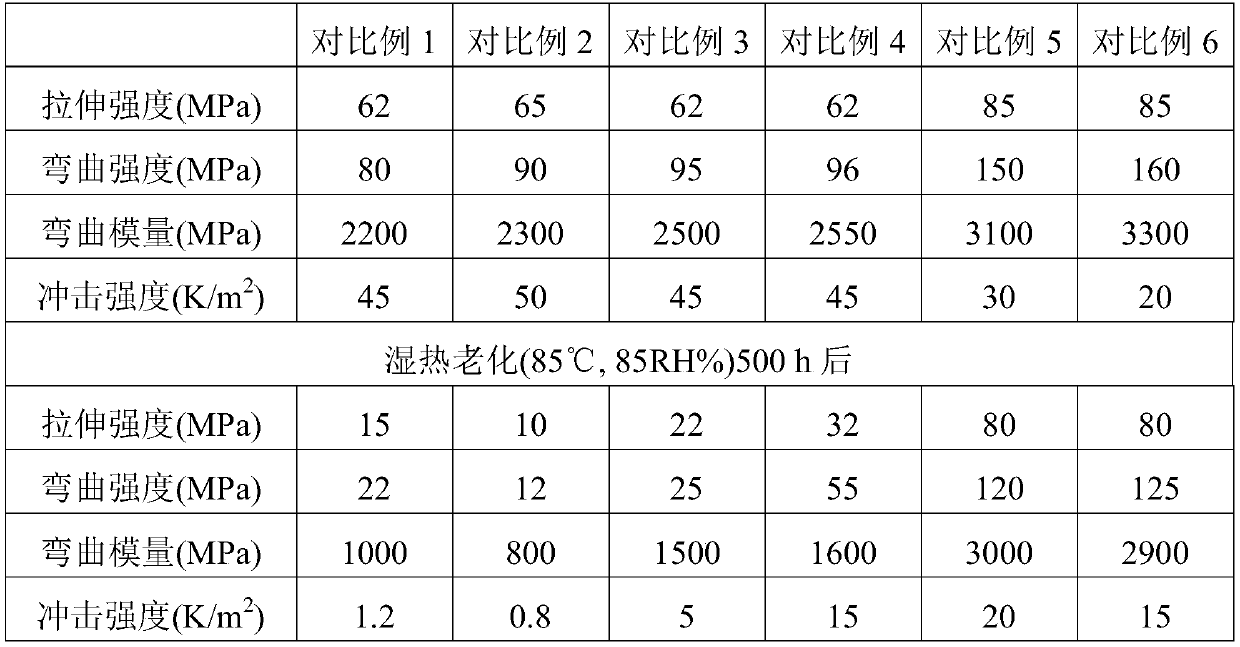

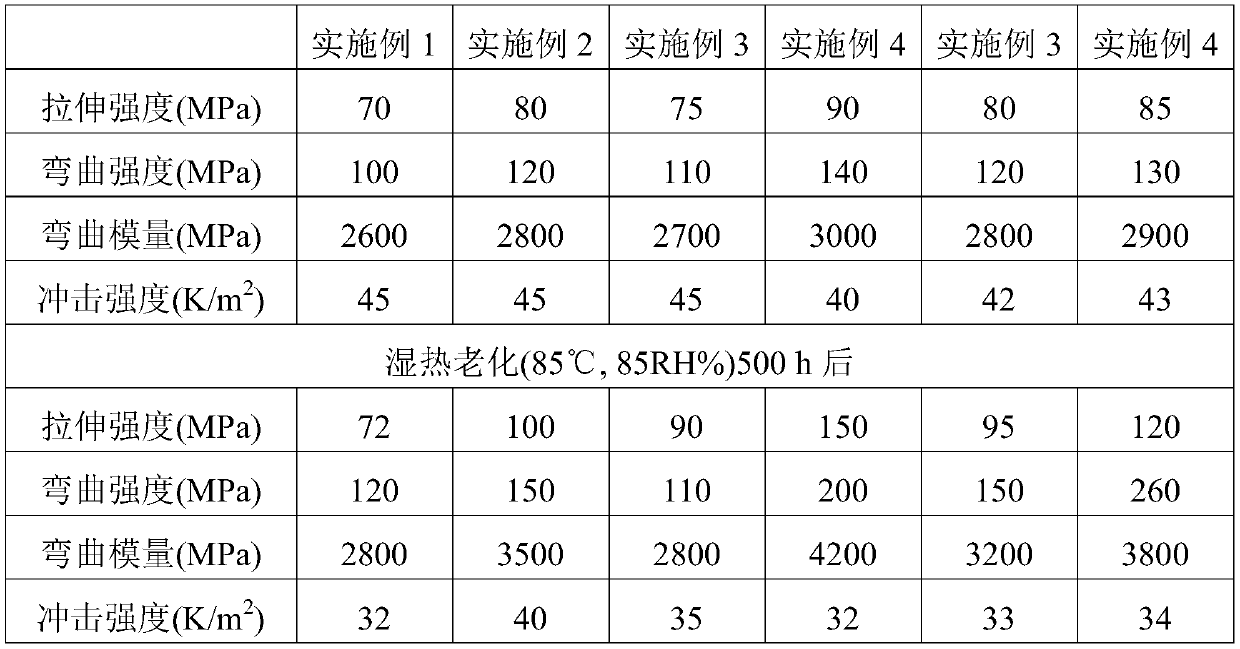

Examples

Embodiment 7

[0040] A preparation method of a PC / ABS alloy resistant to humidity and heat aging, the method comprises 80 parts by weight of 7025PJ type PC resin, 20 parts by weight of ABS3453 resin, 5 parts by weight of Portland cement, 3-(3,5-di-tert-butyl 0.3 parts by weight of n-stearyl-4-hydroxyphenyl) propionate antioxidant, 0.2 parts by weight of simethicone lubricant are mixed uniformly in a high-speed mixer, and the speed of the high-speed mixer is 200-500r / min, Mix for 10-30min, put the uniformly mixed material into a twin-screw extruder for melt blending and extrusion, control the extrusion temperature at 170-230°C, screw speed at 200-500rpm, pressure at 2-3MPa, and pelletize under water After drying, a PC / ABS alloy resistant to heat and humidity aging is obtained.

Embodiment 8

[0042] The difference from Example 3 is that Bayer 2800 PC resin is used as the PC resin.

Embodiment 9

[0044] The difference from Example 2 is that China Resources 425 type phosphate cement is used for cement.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com