Three-dimensional high-temperature continuous heat treatment production system

A technology of production system and heat treatment furnace, which is applied in the field of three-dimensional high-temperature continuous heat treatment production system, can solve the problems that it is difficult to find large-scale continuous heat treatment equipment in the industrial field, low working temperature, and large floor space. The effect of reducing inventory pressure and long production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

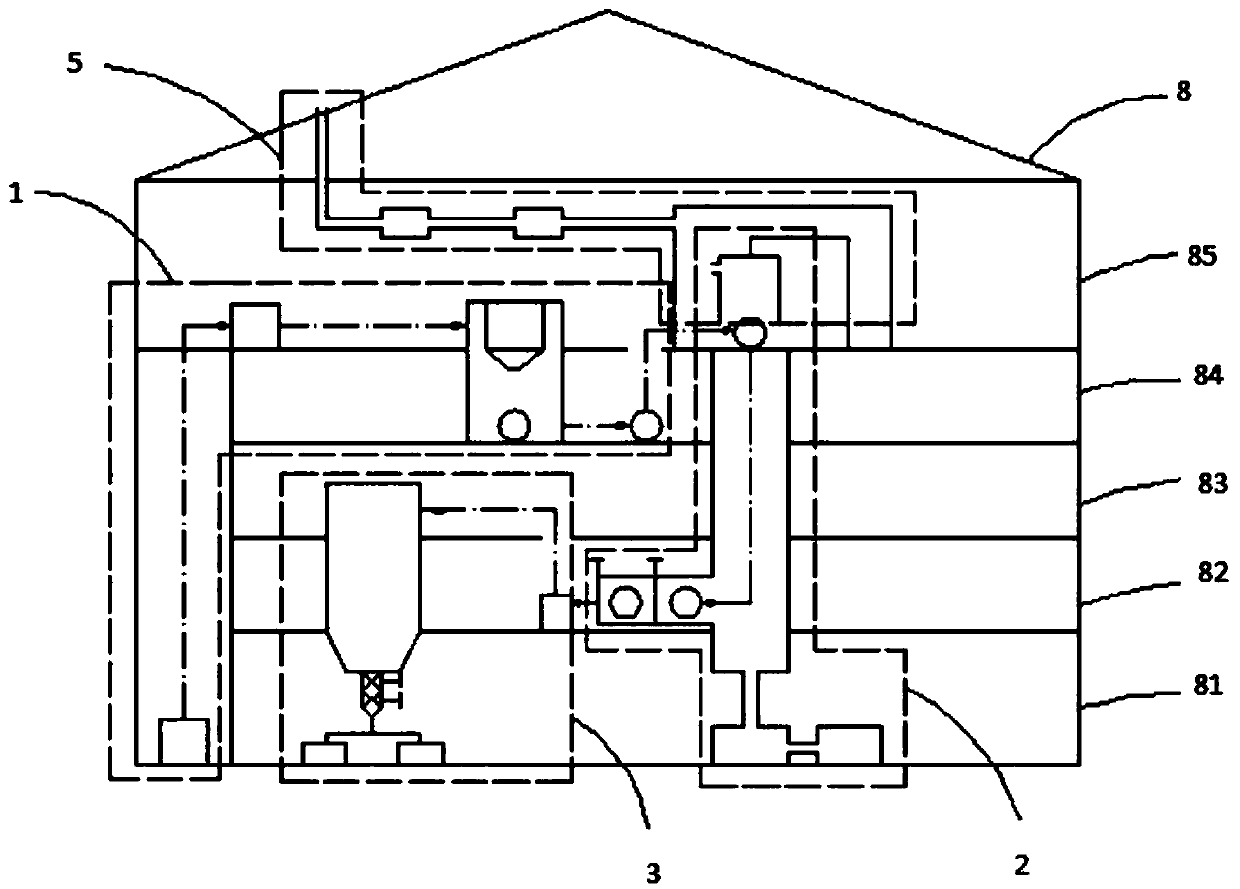

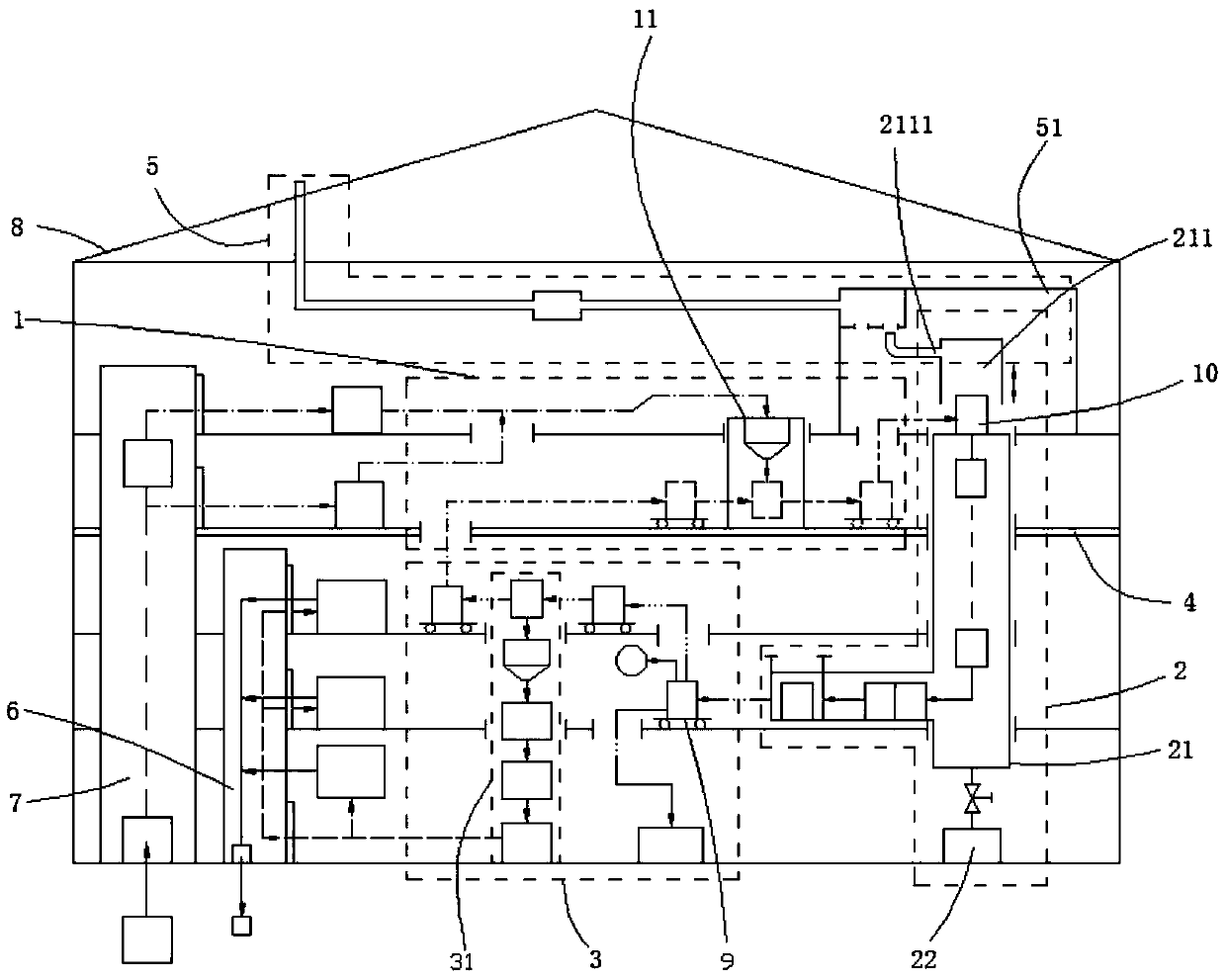

[0033] Such as figure 1 , figure 2 As shown, a three-dimensional high-temperature continuous heat treatment production system is provided. This embodiment is mainly aimed at the graphitization, purification or carbonization of graphite powder raw materials. The production system can be set in a multi-storey workshop 8 with a small footprint , the multi-storey workshop is at least divided into high-level and low-level, high-level and low-level are separated by floor, high-level is used for loading, low-level is used for discharging, high-level is for raw materials, and low-level is for heat-treated products, high-level and low-level materials are not allowed remix. The production system includes a charging module 1, a heat treatment module 2, an unloading module 3 and an electrical control module (not shown), namely figure 1 The modules shown in the dashed box. The heat treatment module 2 includes a vertical high-temperature continuous heat treatment furnace 21. Raw materia...

Embodiment 2

[0046] The difference between this example and Example 1 lies in the difference in heat treatment raw materials. Example 1 is mainly for powdery raw materials, and this example is mainly for high-temperature heat treatment of products. The product can be a raw material processed into a certain shape, which enters the furnace body for heat treatment. The three-dimensional circulation processing mode that raw material adopts is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com