Method for preparing tar extract from waste cigarette butts and application of tar extract in cigarettes

An extract and tar technology, applied in the field of tobacco technology, can solve problems such as not involving the extraction process of discarded cigarette butts, and achieve the effects of reducing inventory pressure, wide source of raw materials, and improving aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The method for preparing tar extract from waste cigarette butts comprises the following steps:

[0032] (1) Pretreatment of discarded cigarette butts: tear off the outer wrapping paper of discarded cigarette butts, and cut the tow into small sections less than 1 cm in length;

[0033] (2) Add 100 g of pretreated waste cigarette butts to 1 L of petroleum ether, microwave extraction power 80 W, and microwave radiation for 5 minutes to obtain an extract;

[0034] (3) After the extract was centrifuged at 1200r / min for 2min, the supernatant was passed through a silica gel column, and the mobile phase was eluted using a mixture of petroleum ether and ethyl acetate with a volume ratio of 20:1, and the eluted components were collected;

[0035] (4) Distill the eluted fraction at 45° C. under a vacuum pressure of 1 mmH, and then dry it in vacuum at 120° C. to obtain a tar extract.

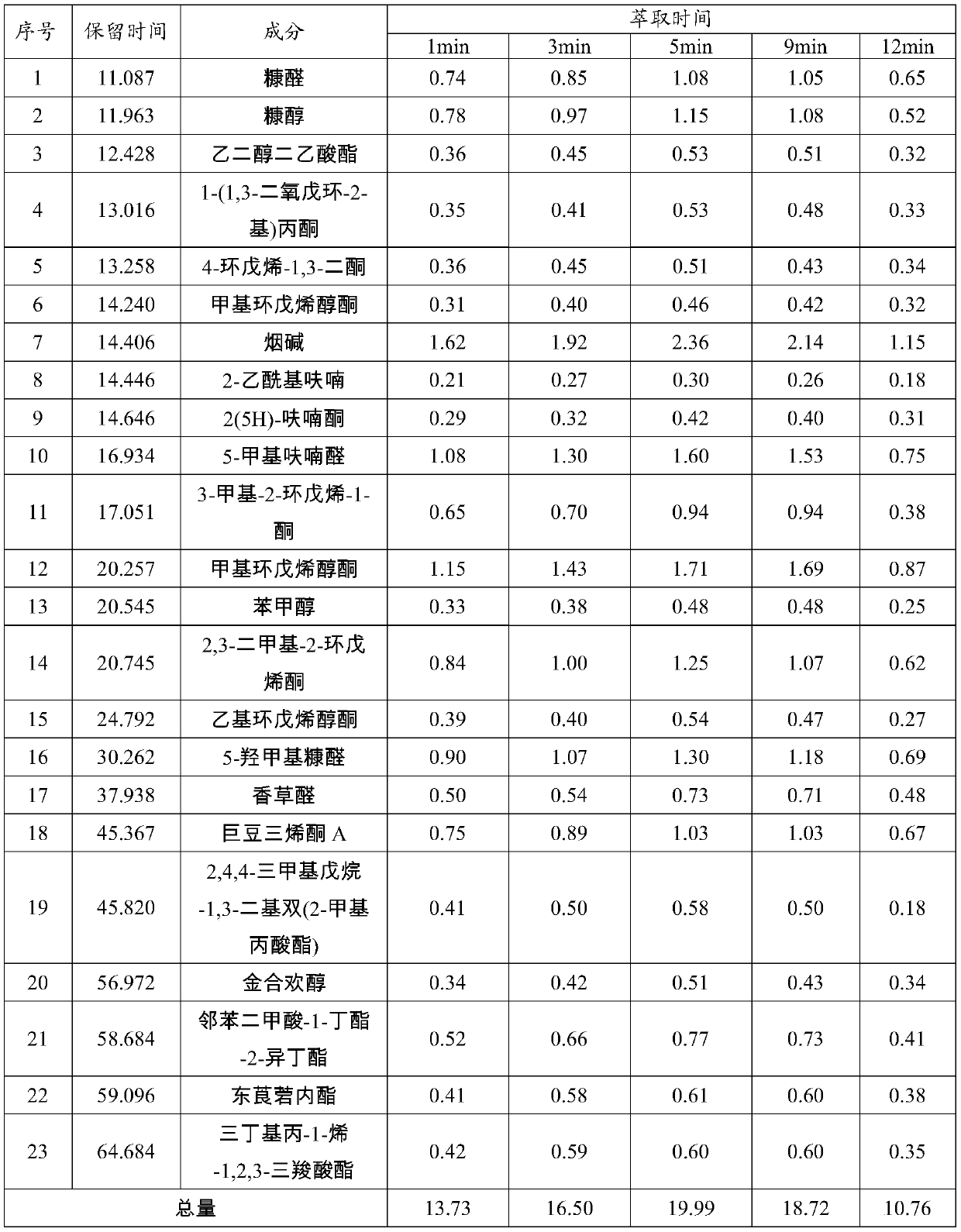

[0036] The tar extract was detected by GC / MS. The main components of the tar extract were furfur...

Embodiment 2

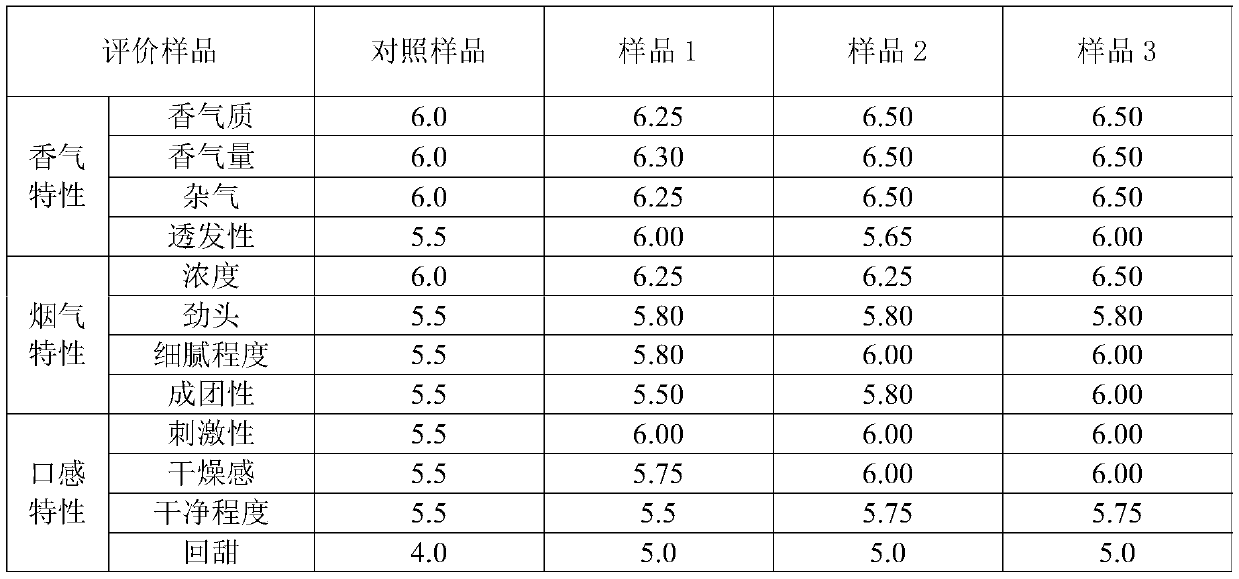

[0054] Example 2 Application of Tar Extract in Cigarette

[0055] The tar extract A, tar extract B, and tar extract C prepared in Example 1 were mixed at a ratio of 1:1:1 to obtain a tar characteristic flavor raw material, which was added at a ratio of 3% by weight of shredded tobacco, The obtained tar characteristic flavor raw material was added to shredded cigarette tobacco to prepare cigarette sample 1.

[0056]The tar extract A, tar extract B, and tar extract C prepared in Example 1 were mixed at a ratio of 1:2:3 to obtain a tar characteristic aroma raw material, which was added at a ratio of 5% by weight of shredded tobacco The prepared tar special flavor raw material was added to cigarette shreds to prepare cigarette sample 2.

[0057] The tar extract A, tar extract B, and tar extract C prepared in Example 1 were mixed at a ratio of 1:2:1 to obtain a tar characteristic aroma raw material, and the addition ratio was 2% by weight of shredded tobacco, The obtained tar c...

Embodiment 3

[0062] Example 3 Selection of preparation method conditions

[0063] 1. Selection of extraction solvent

[0064] Use methanol, dichloromethane, absolute ethanol, glycerin, petroleum ether, and polyethylene glycol 400 to extract the pretreated waste cigarette butts, the ratio of solid to liquid is 1:10 (g / mL), and the microwave extraction power is 80W. The microwave radiation extraction time was 5 minutes, and the extraction was performed once. The influence of different solvents on the extraction effect (the content of components extracted per g of cigarette butts) was compared and analyzed. The test results of the extract solution are shown in Table 2. It can be seen from Table 2 that the extraction effect is the best when using absolute ethanol.

[0065] Extraction effect (mg / g) of different organic solvents of table 2

[0066]

[0067] 2. The choice of microwave radiation time

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com