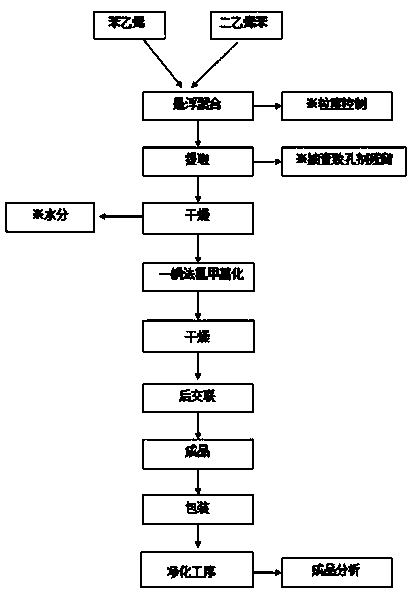

Broad-spectrum blood perfusion macroporous adsorption resin and preparation method thereof

A technology for blood perfusion and adsorption resin, which is applied in the fields of blood circulation treatment, chemical instruments and methods, suction instruments, etc., can solve the problems of irreversible damage to the environment, high thermal explosion of nitrobenzene, etc., and achieves the promotion of specific adsorption, reliable strength, good quality The effect of biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Step (1) white ball polymerization step:

[0051] Add 3.3ml of 0.1% methylene blue, 5g of gelatin, 1.25g of carboxymethyl cellulose, and 400ml of tap water into a 1000ml reactor, start stirring and raise the temperature to 40°C until the liquid in the reactor is mixed evenly to form a water phase; Add 181g of styrene, 19g of 63.3% divinylbenzene, 200g of xylene, and 2g of BPO into the beaker and stir evenly at room temperature to form an oil phase, then pour the oil phase from the beaker into the water phase reactor at room temperature, Stand for stratification, then slowly start stirring to adjust the particle size between 0.4 and 0.8mm, raise the temperature at 80°C for 3 hours for 30 minutes, then raise the temperature for 30 minutes to 90°C for 3 hours, then raise the temperature for 30 minutes at 95°C for 6 hours and then drop At room temperature, obtain polystyrene-divinylphenyl white balls, then extract the white balls with 6 times the volume of methylal, boil th...

Embodiment 2

[0060] Step (1) white ball polymerization step:

[0061] Add 3.3ml of 0.1% methylene blue, 5g of gelatin, 1.25g of carboxymethyl cellulose, and 400ml of tap water to a 1000ml reactor, and start stirring to raise the temperature to 40°C until the liquid in the reactor is mixed evenly to form a water phase; Add 181g of styrene, 19g of 63.3% divinylbenzene, 200g of white oil, and 2g of BPO into the beaker, and stir evenly at room temperature to form an oil phase, then pour the oil phase from the beaker into the water phase reactor at room temperature, and Let it stand for stratification, then slowly start stirring to adjust the particle size between 0.4mm~0.8mm, heat up at 80°C for 30 minutes and hold for 3 hours, then raise the temperature to 90°C for 3 hours in 30 minutes, then heat up at 95°C for 6 hours in 30 minutes Lower the room temperature to obtain polystyrene-divinylphenyl white balls. After the white balls are extracted with 6 times the volume of methylal, boil the bal...

Embodiment 3

[0068] Step (1) white ball polymerization step:

[0069]Add 3.3ml of 0.1% methylene blue, 5g of gelatin, 1.25g of carboxymethyl cellulose, and 400ml of tap water into a 1000ml reactor, start stirring and raise the temperature to 40°C until the liquid in the reactor is mixed evenly to form a water phase; Add 181g of styrene, 19g of 63.3% divinylbenzene, 200g of gasoline, and 2g of BPO into the beaker, stir evenly at room temperature to form an oil phase, then pour the oil phase from the beaker into the water phase reactor at room temperature, and let it stand at room temperature Layering, then slowly start stirring to adjust the particle size between 0.4mm~0.8mm, heat up at 80°C for 30 minutes and keep warm for 3 hours, then rise to 90°C for 30 minutes and keep warm for 3 hours, then raise the temperature at 95°C for 6 hours after 30 minutes, then cool down to room temperature , to obtain polystyrene-divinyl phenyl white balls, and then extract the white balls with 6 times the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com