Porous plastic crystal electrolyte for all-solid-state metal-air battery, preparation method of porous plastic crystal electrolyte and all-solid-state metal-air battery

A technology of solid electrolyte and air battery, which is applied in the manufacture of non-aqueous electrolyte batteries, electrolyte batteries, fuel cell half-cells and secondary battery-type half-cells, etc. It can solve problems such as high hardness and poor electrode contact, and achieve Soft and sticky deformation, improved anti-oxidation performance, and improved discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0086] The present invention also provides a method for preparing a porous plastic crystal composite, comprising the following steps:

[0087] 1) Under the condition of protective gas, heat and mix the plastic crystal, lithium salt, polymer, additive and solvent to obtain a homogeneous mixed solution;

[0088] 2) Composite the homogeneous mixed solution obtained in the above steps on the substrate, and remove the solvent at a certain temperature to obtain a porous plastic crystal composite.

[0089] In the present invention, the morphology, selection and composition of the porous plastic crystal composite in the above-mentioned preparation process, as well as the corresponding optimization principles, can be compared with the corresponding morphology, selection and composition of the aforementioned porous plastic crystal composite, and the corresponding optimization principles. Correspondingly, details are not repeated here.

[0090] In the invention, firstly, under the condi...

Embodiment 1

[0122] Preparation of porous plastic crystal electrolyte: In an argon glove box, mix 0.5 g of succinonitrile, 0.5 g of polyvinylidene fluoride-hexafluoropropylene, 0.13 g of lithium bistrifluoromethanesulfonimide, and 0.2 g of dibutylhydroxytoluene Dissolve in 2 ml of ultra-dry DMSO at 60°C with stirring. The homogeneous mixed solution was poured on a clean glass plate to volatilize the ultra-dry dimethyl sulfoxide at 40° C. to obtain a porous plastic-crystal composite, that is, a porous plastic-crystal solid electrolyte.

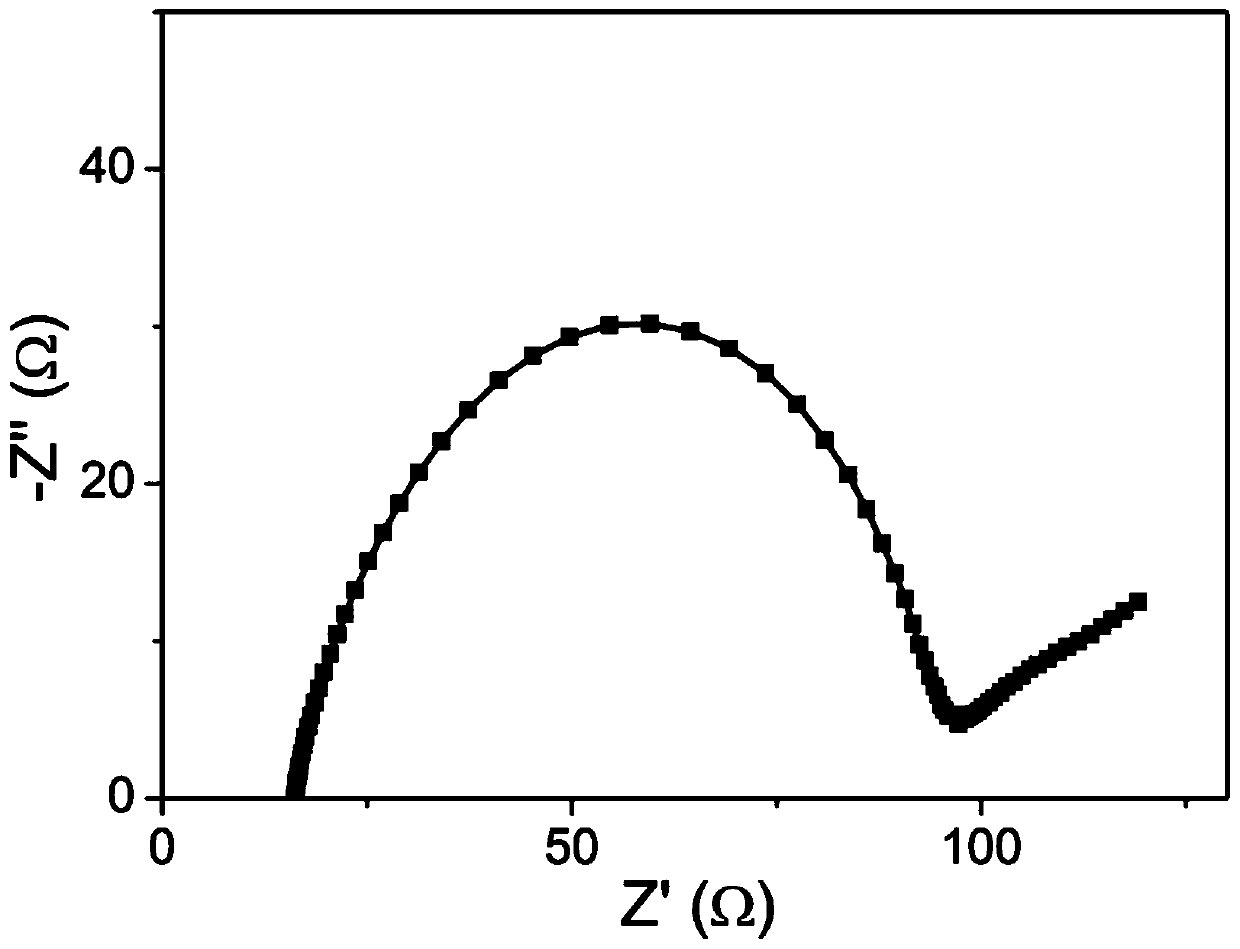

[0123] The porous plastic crystal composite prepared in Example 1 of the present invention was characterized.

[0124] see figure 1 , figure 1 Scanning electron microscope picture of the porous plastic crystal composite prepared in Example 1.

[0125] Depend on figure 1 It can be seen that the porous plastic crystal composite prepared by the present invention has a porous microscopic morphology formed by stacking spherical particles and ellipsoids, wher...

Embodiment 2

[0134] Preparation of porous plastic crystal electrolyte: In an argon glove box, mix 0.5 g of succinonitrile, 0.5 g of polyvinylidene fluoride-hexafluoropropylene, 0.13 g of lithium bistrifluoromethanesulfonimide, and 0.2 g of dibutylhydroxytoluene Dissolve in 3 ml of ultra-dry dimethyl sulfoxide with stirring at 60°C. The homogeneous mixed solution was poured onto a clean glass plate at 40° C. to evaporate the ultra-dry dimethyl sulfoxide to obtain a porous plastic crystal composite.

[0135] The porous plastic crystal composite prepared in Example 2 of the present invention was characterized.

[0136] see image 3 , image 3 Scanning electron microscope picture of the porous plastic crystal composite prepared in Example 2.

[0137] Depend on image 3 It can be seen that the porous plastic crystal composite prepared by the present invention has a porous microscopic morphology formed by stacking spherical particles and ellipsoids, wherein these spherical particles are stac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com