Preparation method of nikkodil

A technology of nicorandil and hydroxyethyl, applied in the field of preparation of nicorandil, can solve problems such as prolonged reaction time, degradation of target substances, consumption of alkali, etc., to solve safety problems, mild reaction process, and reduce environmental protection. effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

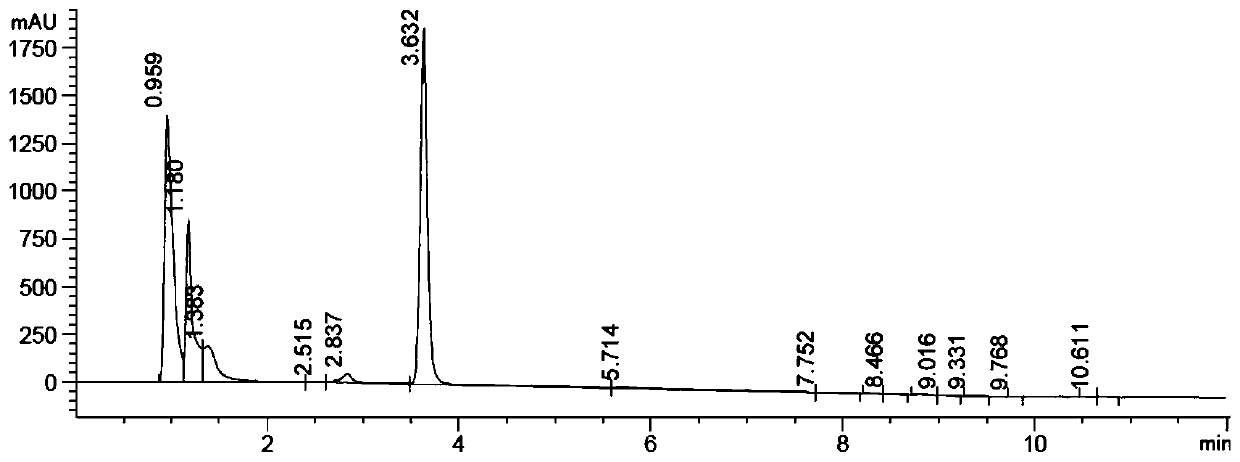

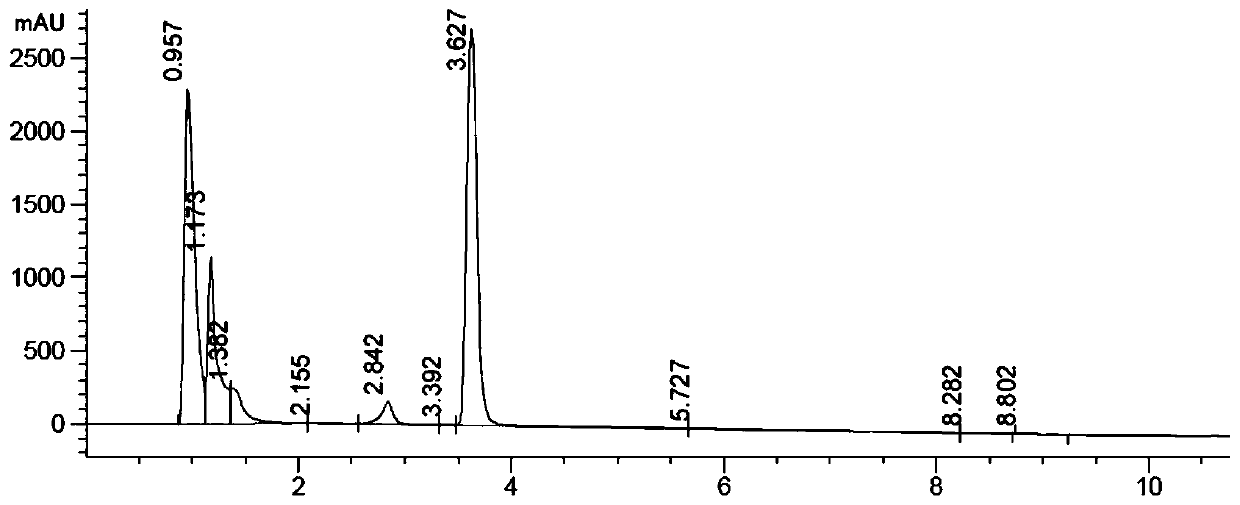

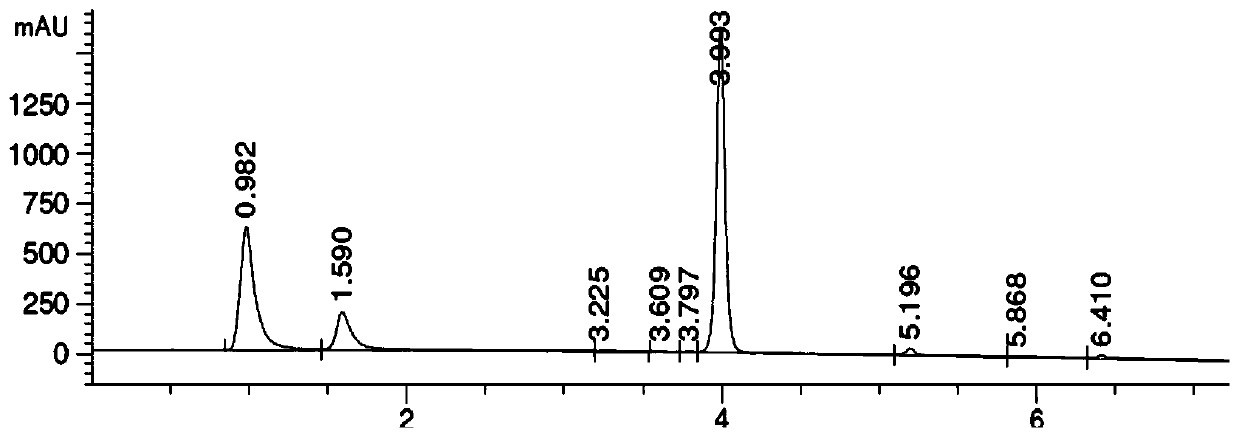

Image

Examples

Embodiment 1

[0040] Add 10 mL of acetonitrile into a 100 mL three-necked reaction flask, and add 2 mL of concentrated nitric acid at one time. The temperature of the system does not rise above 5°C, add 1.8mL of acetic anhydride, and control the temperature not to exceed 40°C. Then, below 25°C, 1.66g (10mmol) of N-(2-hydroxyethyl)nicotinamide was added at one time, and the temperature rise did not exceed 5°C. The reaction was monitored by TLC for 10 minutes and monitored by HPLC for 1 hour to ensure that the content of N-(2-hydroxyethyl)nicotinamide was <1%. If it was still greater than 1%, concentrated nitric acid could be added appropriately. After the reaction is complete, 5 mL of water is added to concentrate the acetonitrile, and the remaining liquid is adjusted to pH=7-8 with concentrated ammonia water, about 25-30 mL is needed. Control the temperature not to exceed 35°C. After the addition, cool to 7±2°C in ice water, stir for 1.5±0.5h, filter, wash with 2mL water to obtain a white...

Embodiment 2-9

[0042] The preparation methods of Examples 2-9 are the same as those of Example 1, except that the reaction raw materials are different. The raw materials of Examples 2-9 are shown in Table 1 below.

[0043] Table 1 embodiment 2-9 raw material and reaction result

[0044]

Embodiment 10

[0046] Add 500mL of acetonitrile, 55mL of fuming nitric acid and 80mL of acetic anhydride into a 1L three-neck flask equipped with a thermometer and a mechanical stirring device, and mix the three. The temperature does not exceed 35°C, and there is no significant exothermic feature. Then add 83g of compound N-(2-hydroxyethyl)nicotinamide at one time, and control the temperature not to exceed 42°C, usually 25±5°C is better. React for 1.5±0.5h, add 100mL of water, concentrate under reduced pressure to remove acetonitrile, adjust the pH of the residue to 7-8 with concentrated ammonia water (about 75-80ml, ie 68-73g), and precipitate a large amount of solids, forming white or slightly yellow Mushy. After filtering, the filter cake was washed with 150 ml of water for 3 times and dried to obtain 92 g of the product with a yield of 81% and a crude product purity of 99.5%. The main impurity is acetate, less than 0.2%, which can be removed by recrystallization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com