Carboxyl modified graphene oxide-metal organic framework composite material and preparation method and application thereof

A metal-organic framework and composite material technology, which is applied in the field of carboxyl-modified graphene oxide@metal-organic framework composite material and its preparation, can solve the problems of limited number of functional groups, low rare earth adsorption capacity, etc., and achieves fast adsorption speed and application range. Wide and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

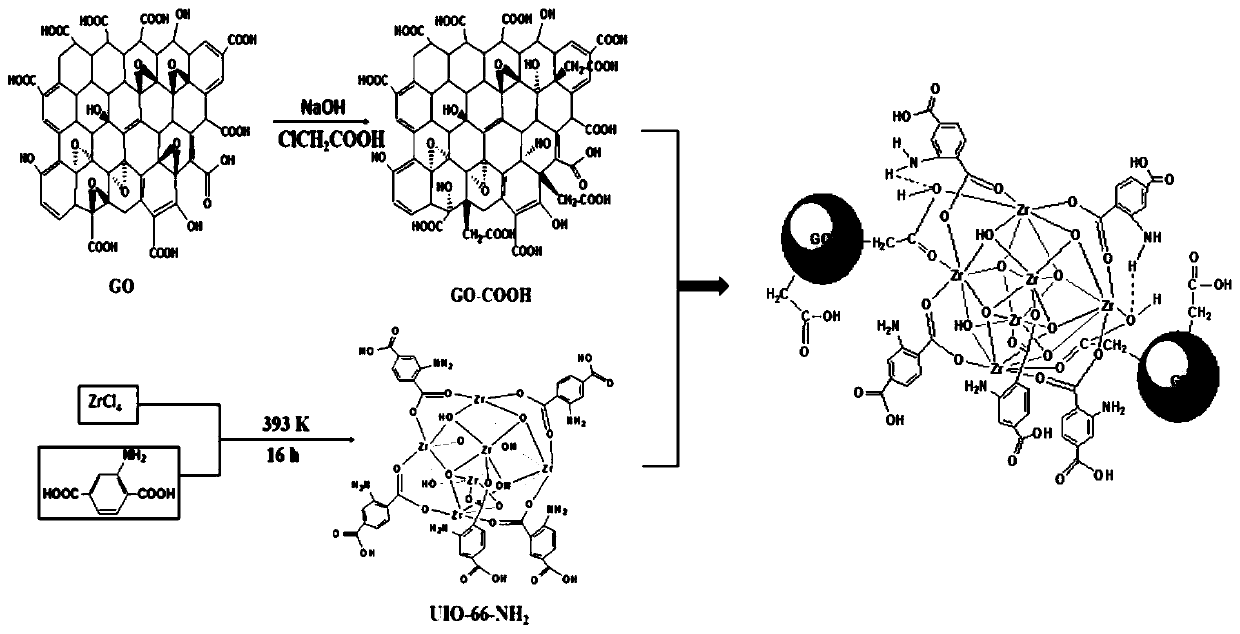

[0034] Example 1 A carboxyl-modified graphene oxide@metal-organic framework composite material

[0035] (1) Carboxyl-modified graphene oxide@metal-organic framework composite GO-COOH-X@UIO-66-NH 2 preparation of

[0036] Synthetic process such as figure 1 shown.

[0037] The preparation method is as follows:

[0038] 1) Preparation of graphene oxide: Mix 180mL of concentrated sulfuric acid, 20mL of concentrated phosphoric acid and 1.5g of graphite powder in an ice bath for 20 minutes, then slowly add 15g of potassium permanganate, slowly heat the solution to 323K, and react for 6 hours. Then the solution was cooled to room temperature and slowly poured into ice water and stirred evenly. Add hydrogen peroxide dropwise to the above solution until the color of the solution changes from earthy yellow to golden yellow, then stop the dropwise addition, and the golden yellow material is graphene oxide.

[0039] 2) Synthesis of carboxyl-modified graphene oxide: the graphene oxide...

Embodiment 2

[0045] Example 2 Carboxyl-modified graphene oxide@metal-organic framework composite material recovery of neodymium

[0046] (1) The effect of the amount of carboxyl-modified graphene oxide on the adsorption performance of Nd(III)

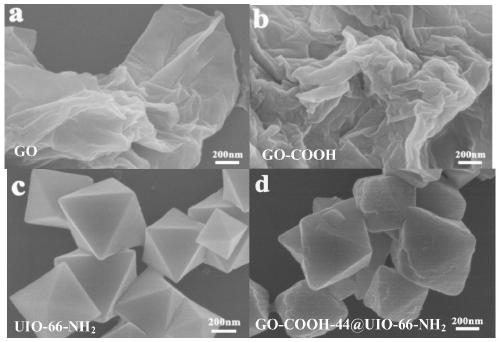

[0047] Method: Take 5 mg of the composite material GO-COOH-9@UIO-66-NH prepared in Example 1 2 、GO-COOH-17@UIO-66-NH 2 、GO-COOH-23@UIO-66-NH 2 、GO-COOH-33@UIO-66-NH 2 、GO-COOH-44X@UIO-66-NH 2 、GO-COOH-50@UIO-66-NH 2 , add 5mL each, 30mg·L -1 Nd(III) solution, shake it in the shaking box for 24h under 303K, the result is as follows Figure 4 shown. As the amount of GO-COOH added increased, the amount of Nd(III) adsorbed by the material also increased. When the amount of GO-COOH added is 80 mg, that is, when X=44, the composite material reaches a higher adsorption capacity, and the adsorption rate of the material does not change significantly when the amount of GO-COOH added continues to increase. This is due to the fact that the surface of G...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com