Self-supporting lithium metal anode and its preparation and application

A self-supporting, metal lithium technology, applied in the direction of negative electrodes, battery electrodes, lithium batteries, etc., can solve the problems of poor lithium affinity of metal lithium negative electrode framework, reduced Coulombic efficiency and cycle life, and inability to achieve uniform deposition, etc., to achieve excellent battery life. Effects of chemical properties, improved performance, and improved long-cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

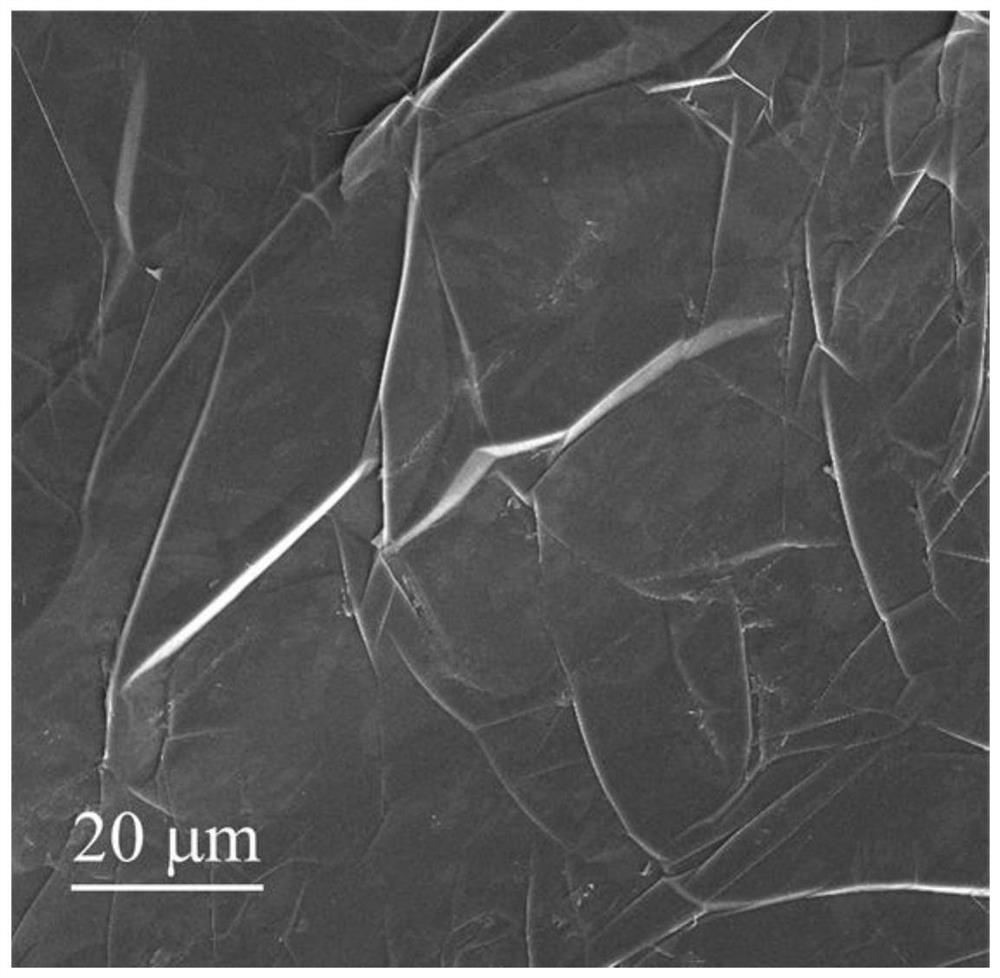

Embodiment 1

[0060] A mixture obtained by mixing polymer polyimide with graphene after carbonization at 800°C for 2 hours was selected, and then pressed into a film in a hot roller press to obtain a thermally conductive carbon film. The film-forming pressure was 6MPa, and the roller The pressing speed is 1.2m / min, and the temperature is 400°C. The obtained thermally conductive carbon film was cut into discs with a diameter of 13 mm. The graphene content in the thermally conductive carbon film is 20%, the porosity is 20%, and the thickness is 0.3mm. Use thermal conductive carbon film as metal lithium working electrode, metal lithium sheet as counter electrode, 1M LiTFSI+DOL-DME+2% LiNO 3 Assemble a button cell for the electrolyte. Electrochemical tests were carried out by loading lithium metal in the thermally conductive carbon film by means of electrochemical deposition. at 1mA / cm 2 current density and 1mAh / cm 2 Under the area capacity, the average Coulombic efficiency reaches 98.6%, ...

Embodiment 2

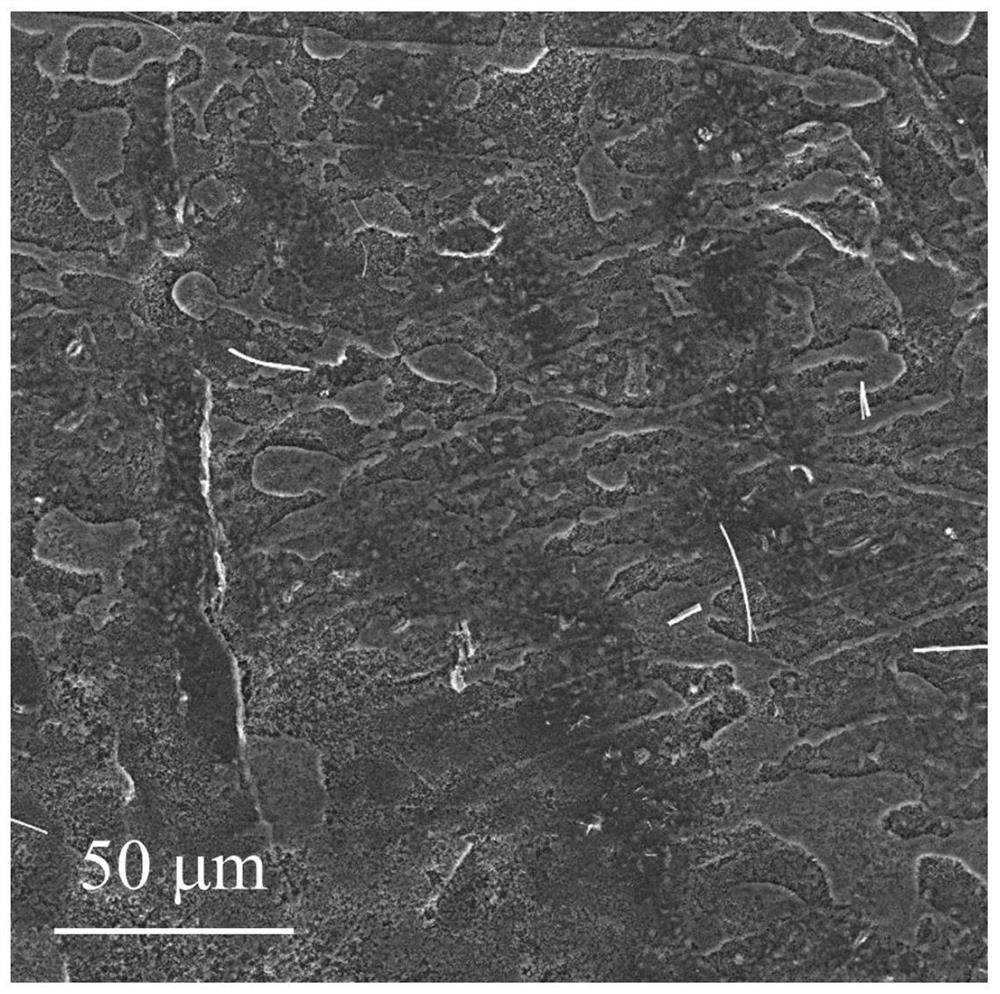

[0062] Compared with Example 1, the difference is that the melting method is used to fill lithium metal and prepare it into a symmetrical battery, specifically:

[0063] The same method as in Example 1 was used to obtain the thermally conductive carbon film disc. Metal lithium is poured into the thermally conductive carbon film by high-temperature melting, and after cooling, the thermally conductive carbon film composite metal lithium is used as the working electrode, and 1M LiTFSI+DOL-DME+2%LiNO 3 Assemble a button-type symmetrical battery for the electrolyte. at 1mA / cm 2 current density and 1mAh / cm 2 Under the area capacity, it can be cycled stably for 300 hours, and the polarization voltage is only 22mV.

Embodiment 3

[0065] Compared with Example 1, the difference is that the content of graphene is changed, specifically:

[0066] A mixture of polymer polyimide carbonized at 800°C for 2 hours and graphene was selected to form a film in a hot roller press. The film forming pressure was 6MPa, the rolling speed was 1.2m / min, and the temperature was 400°C. The obtained thermally conductive carbon film was cut into discs with a diameter of 13 mm. Wherein, the graphene content in the thermally conductive carbon film is 25%, the porosity is 26%, and the thickness is 0.2mm. Use thermal conductive carbon film as metal lithium working electrode, metal lithium sheet as counter electrode, 1M LiTFSI+DOL-DME+2% LiNO 3 Assemble a button cell for the electrolyte. Electrochemical tests were carried out by loading lithium metal in the thermally conductive carbon film by means of electrochemical deposition. at 1mA / cm 2 current density and 1mAh / cm 2 Under the area capacity, the average Coulombic efficienc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com