Implementation method and system suitable for motor industry workshop MES application

An implementation method and workshop technology, applied in manufacturing computing systems, data processing applications, instruments, etc., can solve problems such as inability to guarantee accuracy, low efficiency, and chaotic management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The present invention provides an implementation method applicable to the MES application in the workshop of the motor industry. The specific steps of the method are as follows:

[0047] Step A: First, through the automatic association of the production task with the process route, after the release, the worker is automatically dispatched to the station, and supports the refined management of the task of the workshop station to dispatch the worker to the worker for the second time, so as to realize the support to carry out the process operation according to the dimension of the worker;

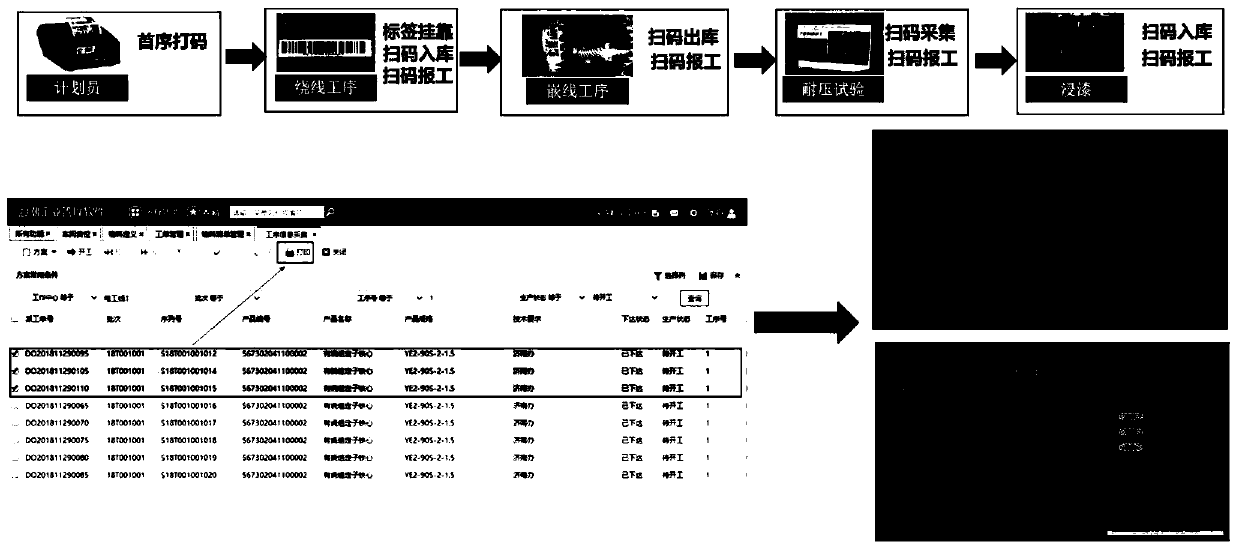

[0048] Step B: Secondly, through the barcode printer and the code scanning gun to cooperate with the workshop station APP to realize the production tracking of the workshop task with the QR code as the carrier, the production process control based on the process control, and realize the paperless and standardized workshop production;

[0049] Step C: Next, the inspection equipment based ...

Embodiment 2

[0062] The present invention provides an implementation system suitable for the application of MES in the workshop of the motor industry. Based on the implementation method of Embodiment 1, the implementation system combines the production characteristics and demand points of the workshop of the small and medium-sized motor industry, and takes the mass production type as the prototype, including the basic data module. , plan management module, ERP system quality management module, workshop station computer application, real-time kanban module;

[0063] Basic data module: The workshop is the center for on-site basic data collection. First, a data collection template is provided, and the workshop administrator collects relevant basic data according to the template, including: factory modeling dimensions, personnel information dimensions, material information and other dimensions;

[0064] The order information in the plan management module is automatically identified and associat...

Embodiment 3

[0069] The invention provides a realization scheme of MES application in a workshop of the motor industry, which has been verified by a certain motor company on-site actual deployment and application.

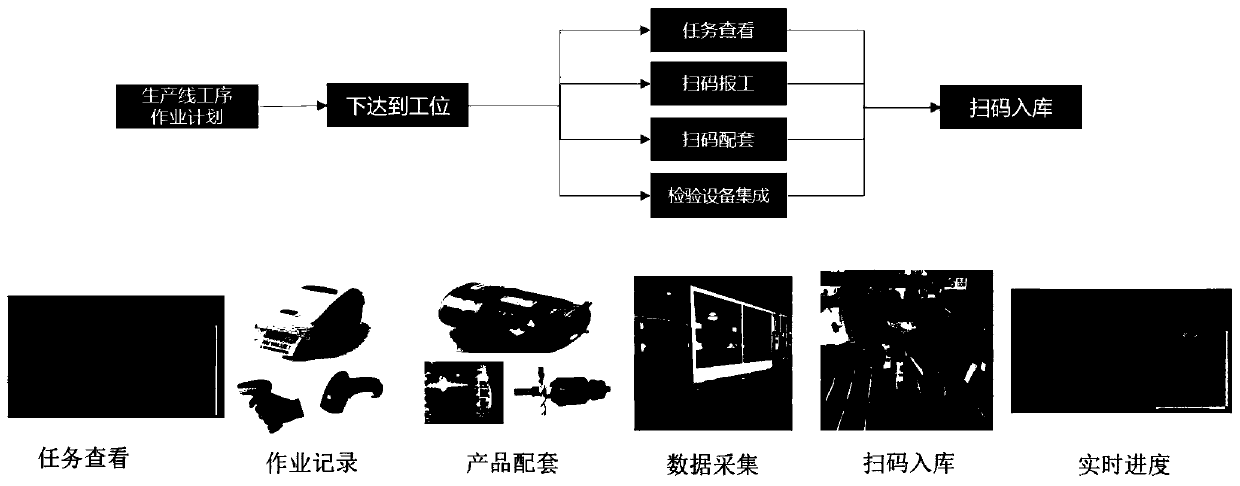

[0070] Refer to attached figure 1 , 2 , MES system business process: including plan decomposition and release, workshop execution steps.

[0071] Through the MES application, the production department, quality department, equipment department, material department, planner, workshop operation and other positions are closely connected in series to achieve a high degree of consistency and sharing of data sources. In the end, it replaced the original paper-based office method in the workshop, standardized the job responsibilities of each dimension, and strictly controlled the serial relationship of workshop procedures and operations, which greatly improved the production efficiency and product qualification rate of the workshop.

[0072] 1. Basic data maintenance

[0073] On-sit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com