Swing impact washing device

A washing device and washing bucket technology, applied in the field of washing, can solve the problems of damaged laundry, difficult to clean sweat stains, cumbersome washing, etc., and achieve the effect of preventing clothes from being entangled, eliminating dead ends for cleaning, and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

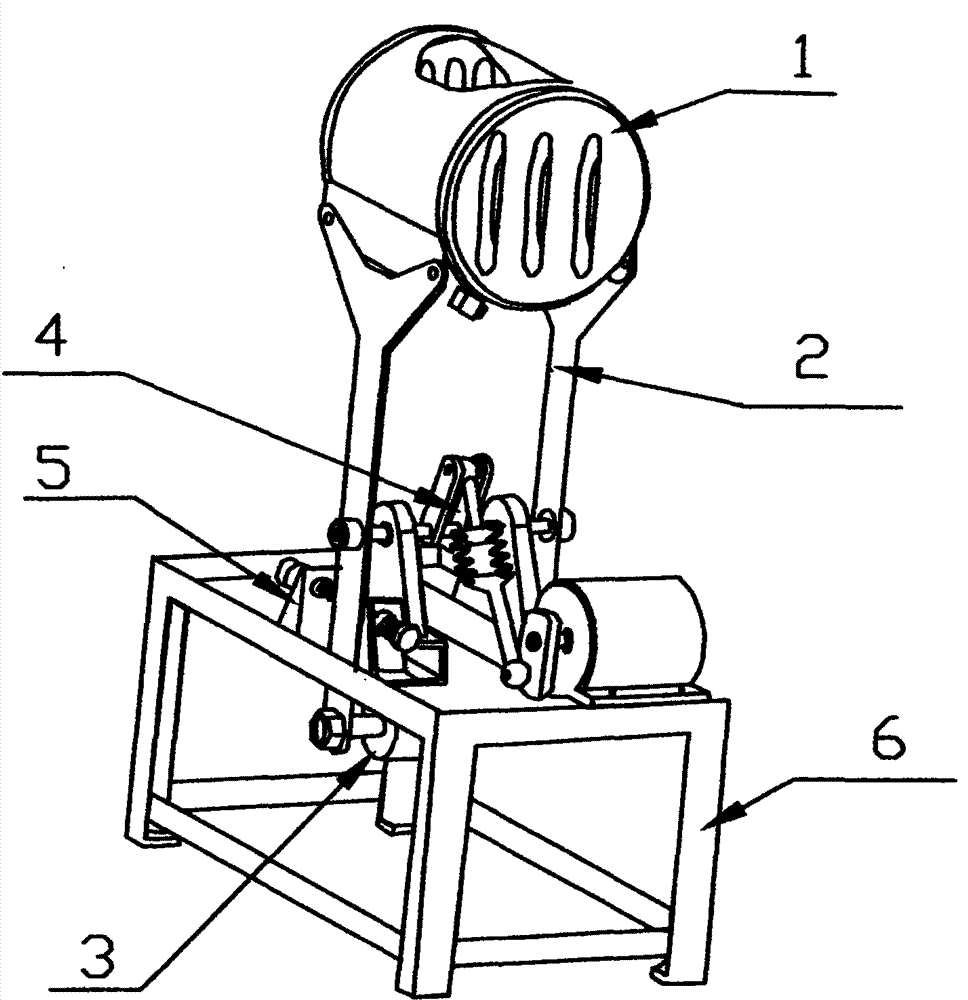

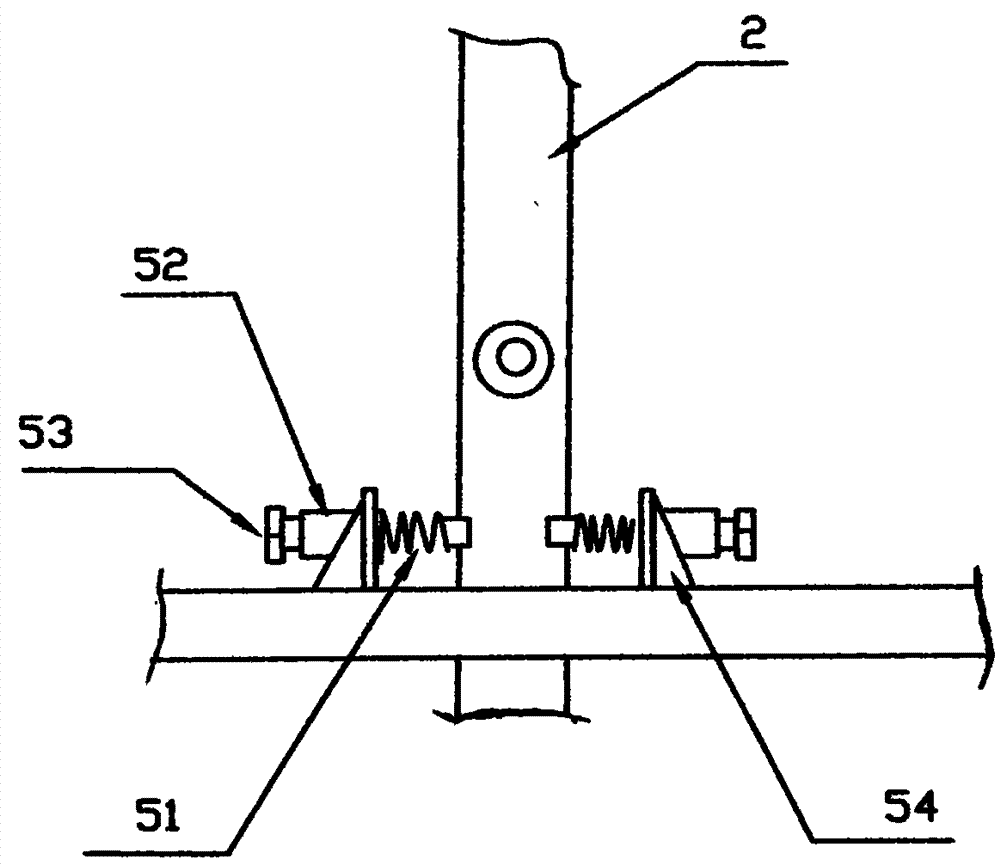

[0046] Such as figure 1 , image 3 , Figure 6 ~ Figure 7 , Figure 9 to Figure 14 , the swing impact washing device is mainly composed of a washing bucket 1, a rocker arm 2, a counterweight 3, a mechanical swing drive device 41, a balance spring mechanism 5, a base 6, a toggle body 11, an impact body 12, a water inlet 13, and a water outlet 14 , deceleration driving mechanism 411, torsion center shaft 412, support frame 413, crank 414, swing connecting rod 415, swing rod 416, connecting rod 417, tension and compression spring 418, spring 51, spring adjustment sleeve 52, spring adjustment screw 53 and adjustment Sleeve support 54 constitutes.

[0047] Wherein, the washing tub 1 is horizontally arranged on the upper end of the rocker arm 2, the washing tub 1 is a cylindrical shell structure, the rocker arms 2 are two, and the two rocker arms 2 are symmetrically arranged on the side of the washing tub 1 On the wall, the lower end of the rocker arm 2 is fixed with a counterwe...

Embodiment 2

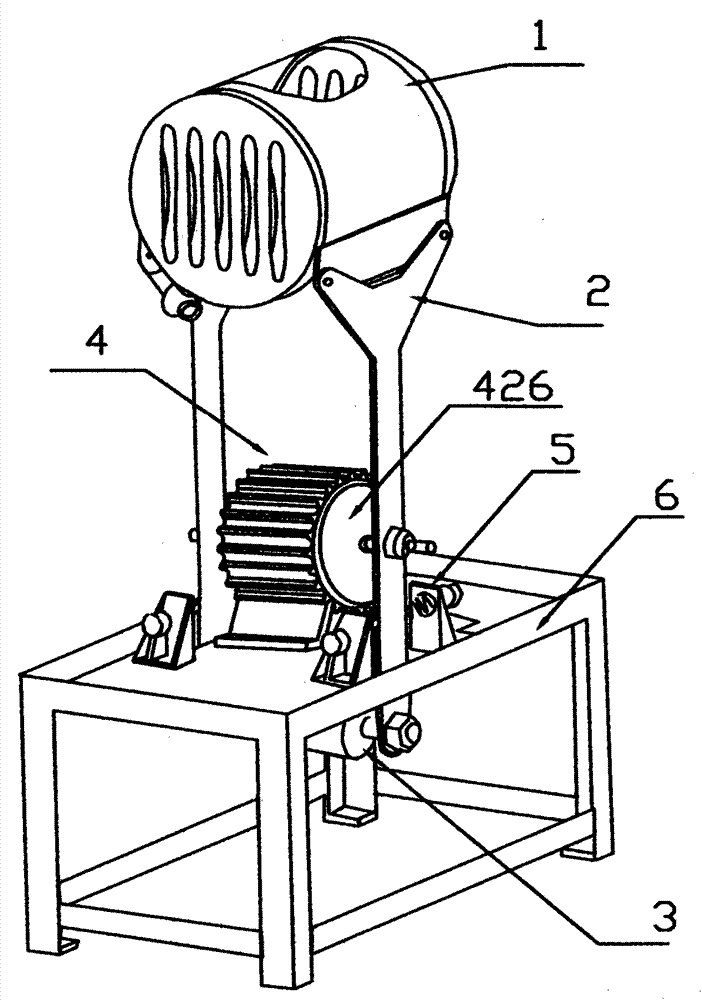

[0066] Such as Figure 2 ~ Figure 3 , Figure 8 ~ Figure 14 , the swing impact washing device is mainly composed of a washing bucket 1, a rocker arm 2, a counterweight 3, an electromagnetic swing driving device 41, a balance spring mechanism 5, a base 6, a toggle body 11, an impact body 12, a water inlet 13 and a water outlet 14 composition.

[0067] The swing driving device 4 adopted in this embodiment is an electromagnetic swing driving device 42, and the structure of the electromagnetic swing driving device 42 is: including a stator 421, a rotor 422, a rotor central shaft 423, a magnetic pole piece 424 and a coil 425, and the stator 421 Fixed on the base 6, the magnetic pole pieces 424 are multiple and symmetrically arranged on the inner surface of the stator 421, the coils 425 are wound on the magnetic pole pieces 424, and the rotor 422 is arranged at the inner center of the stator 421 through the rotor central axis 423 place and drive the rotor central axis 423 to move,...

Embodiment 3

[0070] Such as Figure 3 ~ Figure 4 , Figure 8 ~ Figure 14 , the swing impact washing device is mainly composed of a washing bucket 1, a rocker arm 2, a counterweight 3, an electromagnetic swing driving device 41, a balance spring mechanism 5, a base 6, a toggle body 11, an impact body 12, a water inlet 13 and a water outlet 14 composition.

[0071] The counterweight 3 in this embodiment is arranged on the upper part of the plane of the base 6, the lower end of the rocker arm 2 is located above the base 6, the lower end of the rocker arm 2 is provided with a counterweight 3, and the counterweight 3 is two are respectively fixed on the lower ends of the two rocker arms 2.

[0072] Other structures, component functions and working methods of this embodiment are the same as those of Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com