Fe-Al-series metal film and preparation method thereof

A metal membrane, fe-al technology, applied in separation methods, chemical instruments and methods, membrane technology, etc., can solve the problems of large filtration resistance, expand the application range of metal porous membranes, and low flux, and achieve low filtration resistance, Improve the effect of membrane material performance defects and high filtration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

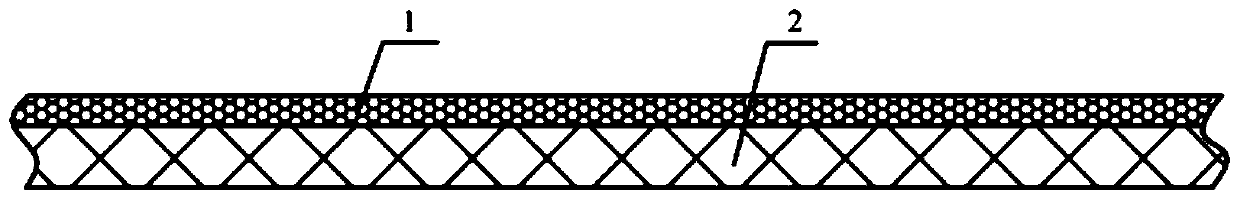

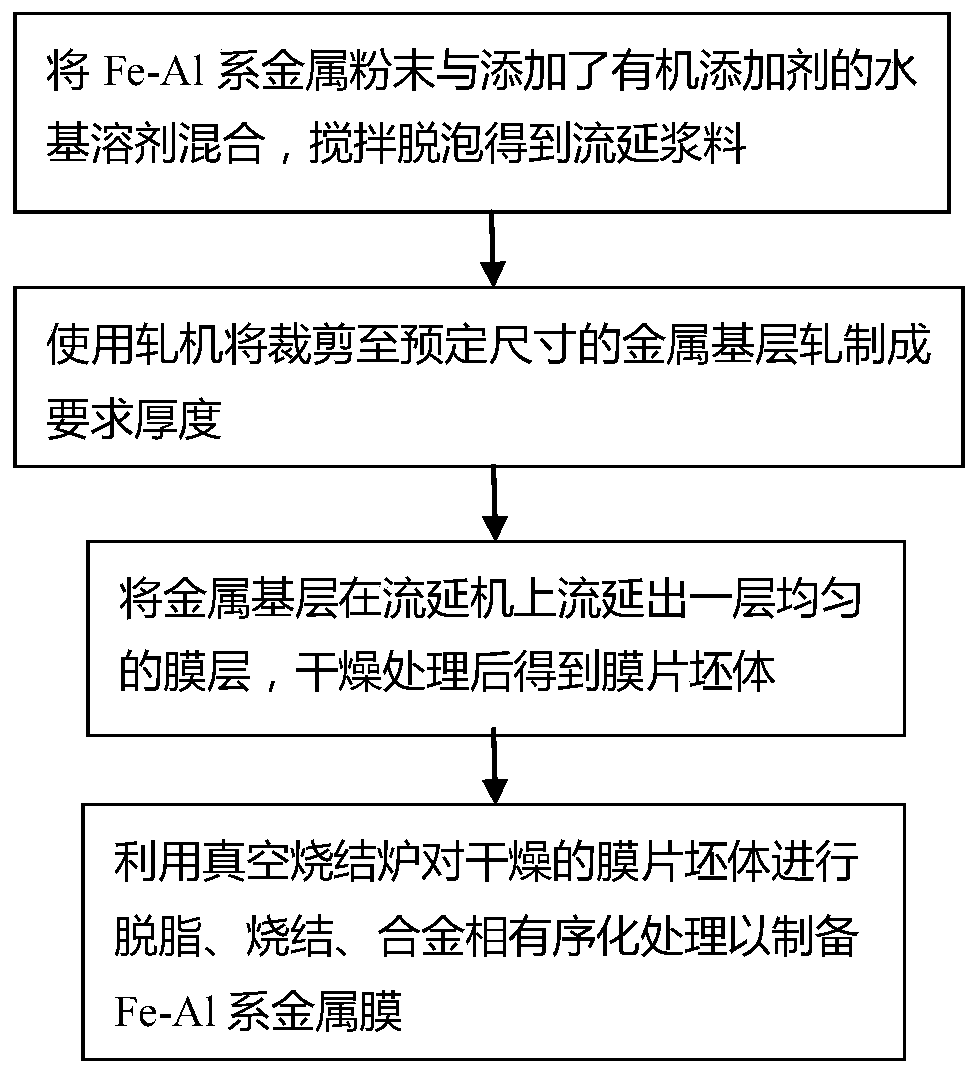

[0046] 1. Slurry preparation: Mix -500 mesh FeAl powder with a water-based solvent added with organic additives at a ratio of 1:2.5 for more than 1 hour, perform defoaming treatment for later use, and select organic additives such as methyl cellulose, vinyl alcohol, and acrylic acid. One or more of triol, polyethylene glycol and dibutyl phthalate.

[0047] 2. Wire mesh rolling: Roll the 316L stainless steel wire mesh with a cut size of 320*630mm to a thickness of 0.1-0.2mm, and keep the flatness below 0.05mm.

[0048] 3. Tape casting: adjust the distance between the cutting tools of the casting machine, the front knife is 0.5-0.7mm, the back knife is 0.4-0.6mm, the casting speed is 0.01-0.2mm / s, and the preheating temperature is set to 45-55°C in zone 1, 2 , 3 zone temperature 50-60 ℃. Put the screen under the cutter and fix it on the casting substrate, add the slurry and cast to form a screen membrane, clean the remaining powder on the membrane after drying, check whether th...

example 2

[0051] 1. Slurry preparation: -500 mesh Fe 3 Al powder and water-based solvent added with organic additives were mixed at a ratio of 1:3 for more than 1 hour, and then used after defoaming treatment. The organic additives were methyl cellulose, vinyl alcohol, glycerol, polyethylene glycol and phthalate. One or more of dibutyl formate.

[0052] 2. Wire mesh rolling: Roll the 310S stainless steel wire mesh with a cut size of 500*800mm to a thickness of 0.1-0.2mm, and keep the flatness below 0.05mm.

[0053] 3. Tape casting: adjust the distance between the cutting tools of the casting machine, the front knife is 0.5-0.7mm, the back knife is 0.4-0.6mm, the casting speed is 0.01-0.2mm / s, and the preheating temperature is set to 45-55°C in zone 1, 2 , 3 zone temperature 50-60 ℃. Put the screen under the cutter and fix it on the casting substrate, add the slurry and cast to form a screen membrane, clean the remaining powder on the membrane after drying, check whether there are leak...

example 3

[0056] 1. Slurry preparation: Mix -500 mesh FeCrAl powder with water-based solvent with organic additives at a ratio of 1:3.3 for more than 1 hour, perform defoaming treatment for later use, and select organic additives such as methyl cellulose, vinyl alcohol, and glycerin One or more of alcohol, polyethylene glycol and dibutyl phthalate.

[0057] 2. Wire mesh rolling: Roll the cut FeCrAl wire mesh with a size of 550*1050mm to a thickness of 0.2-0.3mm, and keep the flatness below 0.05mm.

[0058] 3. Tape casting: adjust the distance between the cutting tools of the casting machine, the front knife is 0.4-0.6mm, the rear knife is 0.5-0.7mm, the casting speed is 0.01-0.2mm / s, the preheating temperature is set to 45-55℃ in zone 1, 2 , 3 zone temperature 50-60 ℃. Put the screen under the cutter and fix it on the casting substrate, add the slurry and cast to form a screen membrane, clean the remaining powder on the membrane after drying, check whether there are leaks or cracks, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com