Preparation method of high-energy-density and high-voltage graphite-zinc-based ion battery based on aqueous electrolyte

A high energy density, water-based electrolyte technology, applied in the field of preparation of water-based electrolyte graphite-zinc-based ion batteries, can solve the problems of narrow voltage window, low voltage, low energy density, etc., and achieve the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing a high-energy density, high-voltage graphite-zinc-based ion battery based on an aqueous electrolyte, comprising the following steps:

[0030] (1) Synthesis of aqueous electrolyte:

[0031] The configuration concentration is 5.89mol kg -1 (30mol / L) zinc chloride and 0.38mol kg -1 (0.4mol / L) potassium bromide aqueous solution, the molar ratio of zinc chloride and potassium bromide in the aqueous solution is 750:1, as the electrolyte.

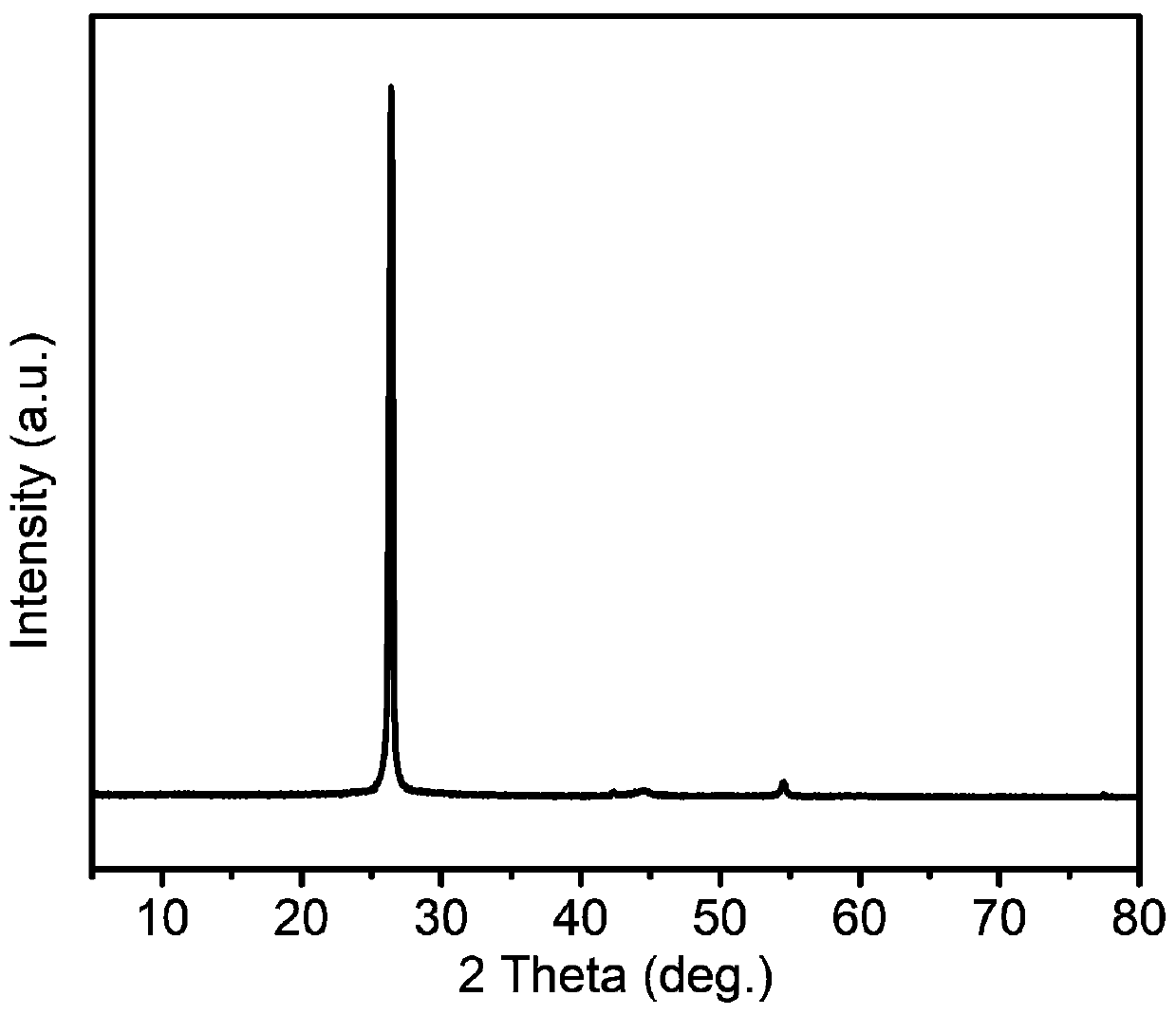

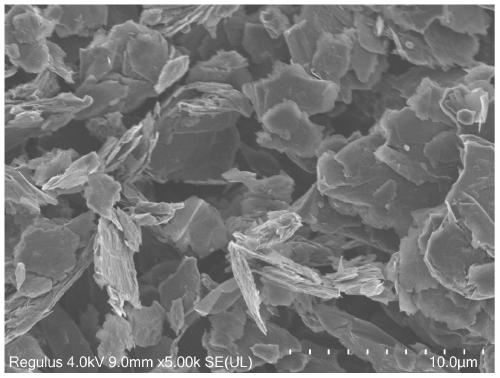

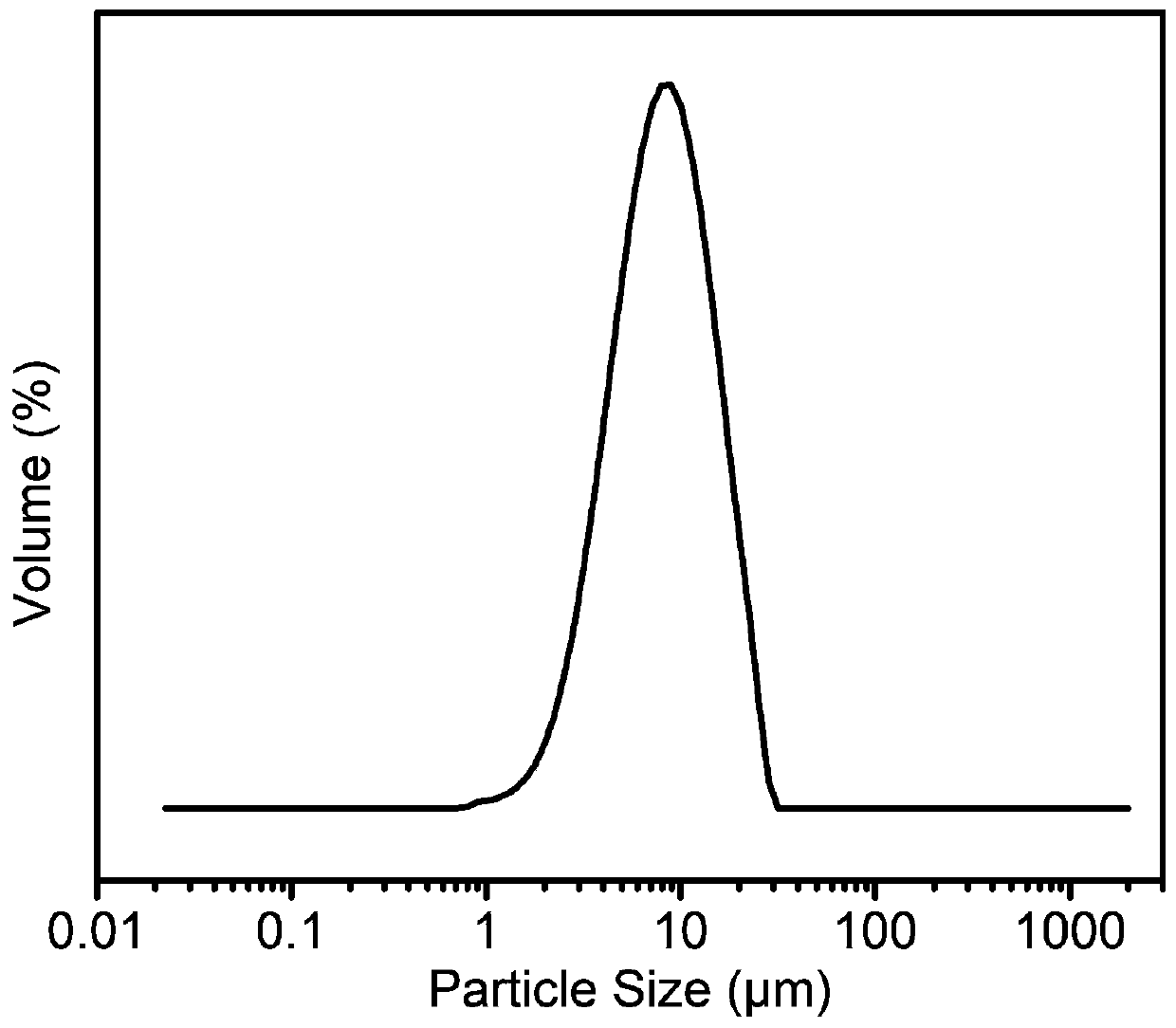

[0032] (2) 900 mg of artificial graphite positive electrode material and 3.33 g of 3% sodium carboxymethyl cellulose aqueous solution were fully stirred, then coated with a wet film-making method, and vacuum-dried at 80° C. for 10 hours to obtain a positive electrode sheet. The material characterization of the graphite cathode material used is as follows figure 1 , powder X-ray results show the phase purity of graphite; figure 2 The field emission scanning electron microscope image shows that the morphology of g...

Embodiment 2

[0035] A method for preparing a high-energy density, high-voltage graphite-zinc-based ion battery based on an aqueous electrolyte, comprising the following steps:

[0036] (1) Synthesis of electrolyte:

[0037] Dissolve zinc chloride (81.78g, 0.6mol) and potassium bromide (0.47g, 0.004mol) in water (20mL) to obtain potassium bromide (0.2mol / L) and zinc chloride (30mol / L) the electrolyte;

[0038] Dissolve zinc chloride (81.78g, 0.6mol) and potassium bromide (0.95g, 0.008mol) in water (20mL) to obtain potassium bromide (0.4mol / L) and zinc chloride (30mol / L) the electrolyte;

[0039]Dissolve zinc chloride (81.78g, 0.6mol) and potassium bromide (1.90g, 0.016mol) in water (20mL) to obtain potassium bromide (0.8mol / L) and zinc chloride (30mol / L) the electrolyte;

[0040] Dissolve zinc chloride (81.78g, 0.6mol) and potassium bromide (3.57g, 0.03mol) in water (20mL) to obtain potassium bromide (1.5mol / L) and zinc chloride (30mol / L) of electrolyte.

[0041] (2) 900 mg of artific...

Embodiment 3

[0044] A method for preparing a high-energy density, high-voltage graphite-zinc-based ion battery based on an aqueous electrolyte, comprising the following steps:

[0045] (1) Synthesis of electrolyte:

[0046] Dissolve zinc chloride (81.78g, 0.6mol) and potassium bromide (0.95g, 0.008mol) in water (20mL) to obtain potassium bromide (0.4mol / L) and zinc chloride (30mol / L) of electrolyte.

[0047] (2) 850 mg of artificial graphite positive electrode material, 50 mg of Super P conductive agent, and 3.33 g of 3% sodium carboxymethylcellulose aqueous solution were fully stirred, and then coated with a wet film-making method, and vacuum-dried at 60 ° C for 12 hours to obtain a positive electrode piece. The material characterization of the graphite cathode material used is as follows figure 1 , powder X-ray results show the high purity of graphite; figure 2 The field emission scanning electron microscope image shows that the morphology of graphite is micron-sized particles; i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com