High-nickel positive electrode material, nickel-cobalt precursor material, preparation method of high-nickel positive electrode material, preparation method of nickel-cobalt precursor material and lithium ion battery

A cathode material and precursor technology, applied in battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve problems such as reducing the specific capacity, poor durability, and affecting rate performance of high-nickel cathode materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

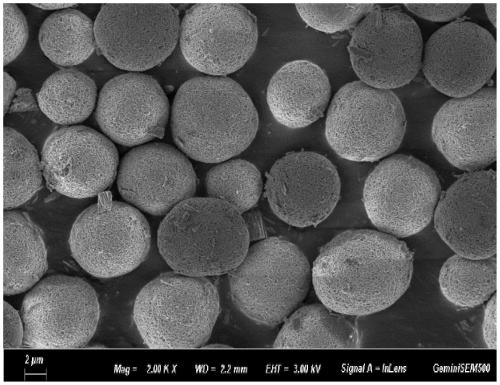

Image

Examples

Embodiment 1

[0111] 5g Ni 0.9 co 0.1 (OH) 2Disperse in 50 mL of deionized water, and adjust the pH to 9.0 with ammonia water to obtain a nickel-cobalt-aluminum hydroxide dispersion. Prepare an aqueous aluminum sulfate solution with a concentration of 2mol / L, add ammonium oxalate and mix well, the molar ratio of ammonium oxalate to aluminum sulfate is 2:1, and a mixed solution of aluminum sulfate and ammonium oxalate is obtained. Before the mixed solution is added, it is stirred so as not to form a precipitate, and the stirring speed is 10-1000 r / min. Add the "mixed solution of aluminum sulfate and ammonium oxalate" to the nickel-cobalt-aluminum hydroxide dispersion at a rate of 1mL / min, during which the flow rate of ammonia water is controlled to be 1-20mL / min and the concentration of ammonia water is 0.3-3mol / L Thereby controlling the pH of the whole reaction system to be 9.0. After the feeding is completed, the mixture is continuously stirred at a speed of 200-800 r / min for 4 hours, ...

Embodiment 2

[0113] 5g Ni 0.85 co 0.15 (OH) 2 Disperse in 30 mL of deionized water, and adjust the pH to 8.5 with ammonia water to obtain a nickel-cobalt-aluminum hydroxide dispersion. Prepare an aqueous aluminum sulfate solution with a concentration of 1 mol / L, add ethylenediamine and mix well, and the molar ratio of ethylenediamine to aluminum sulfate is 3:1 to obtain a mixed solution of aluminum sulfate and ethylenediamine. Before the mixed solution is added, it is stirred so as not to form a precipitate, and the stirring speed is 10-1000 r / min. Add the "mixed solution of aluminum sulfate and ethylenediamine" to the nickel-cobalt-aluminum hydroxide dispersion at a rate of 2mL / min, during which the flow rate of ammonia water is controlled to be 1-20mL / min and the concentration of ammonia water is 0.3-3mol / min. L thereby controlling the pH of the entire reaction system to be 8.5. After the feeding is completed, the mixture is continuously stirred at a speed of 200-800 r / min for 6 hour...

Embodiment 3

[0115] 10g Ni 0.7 co 0.3 (OH) 2 Disperse in 500mL of deionized water, and adjust the pH to 9.5 with ammonia water to obtain a nickel-cobalt-aluminum hydroxide dispersion. Prepare an aqueous solution of aluminum sulfate with a concentration of 4mol / L, then add sodium oxalate and mix well. The molar ratio of sodium oxalate to aluminum sulfate is 5:1 to obtain a mixed solution of aluminum sulfate and ammonium oxalate. Stir the mixed solution before adding it In order not to form a precipitate, the stirring speed is 10-1000r / min. Add the "mixed solution of aluminum sulfate and ammonium oxalate" to the nickel-cobalt-aluminum hydroxide dispersion at a rate of 5mL / min, during which the flow rate of ammonia water is controlled to be 1-20mL / min and the concentration of ammonia water is 0.3-3mol / L Thereby controlling the pH of the whole reaction system to be 9.5. After the feeding is completed, the mixture is continuously stirred at a speed of 200-800 r / min for 5 hours, filtered and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com