A kind of preparation method of xylo-oligosaccharide

A technology of xylooligosaccharides and xylans, which is applied in the direction of fermentation, can solve the problems of resource waste, environmental pollution, and low overall use value, and achieve the effect of reducing pretreatment costs, reducing environmental pollution, and improving comprehensive economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

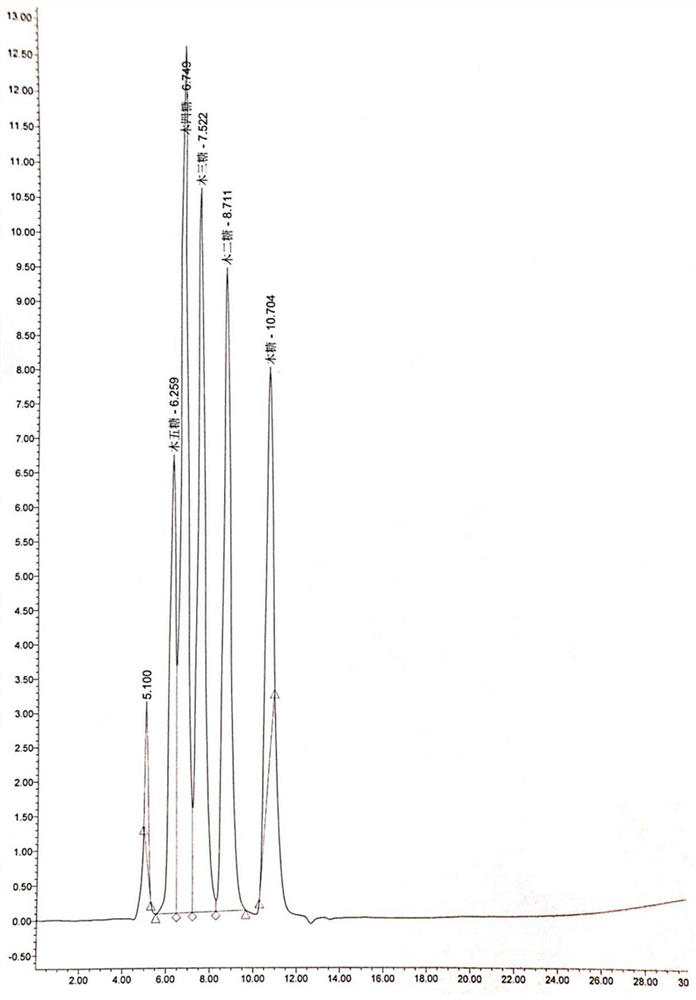

Image

Examples

Embodiment 1

[0046] The present embodiment relates to a kind of preparation method of xylo-oligosaccharide, comprises the following steps:

[0047] 1) Wash and air-dry the bagasse, pulverize it with a pulverizer, and sieve it to 20 meshes to control its water content to ≤5%. On a dry basis, put 10kg of bagasse in a pressure-resistant reactor, and then add 100L of 50% to the reactor (v / v) ethanol aqueous solution, add 1.0kg sodium hydroxide at the same time, heat to 100 ℃ after sealing, process 2h, cool down, obtain filtrate and filter residue after filtering;

[0048] 2) After the filtrate is concentrated by rotary evaporation, the filtrate is subjected to alcohol precipitation with 3 times the volume of 95% (v / v) ethanol solution to obtain a xylan precipitation; the xylan is filtered to obtain a secondary filtrate, which is subjected to rotary concentration , recovery of ethanol; then the lignin is separated by acid precipitation, and the residue after the separation of lignin is burned t...

Embodiment 2

[0052] The present embodiment relates to a kind of preparation method of xylo-oligosaccharide, comprises the following steps:

[0053] 1) Wash and air-dry the bagasse, pulverize it with a pulverizer, and sieve it into 20 meshes to control its water content to ≤5%. On a dry basis, put 10kg of the bagasse in a pressure-resistant reaction kettle, and then add 100L of 50% (v / v) ethanol aqueous solution, add 1.5kg sodium hydroxide at the same time, heat to 110 ℃ after sealing, treat for 1.5h, cool down, obtain filtrate and filter residue after filtering;

[0054] 2) After the filtrate is concentrated by rotary evaporation, it is extracted with 3 times the volume of 95% (v / v) ethanol precipitation to obtain a xylan precipitate; the secondary filtrate obtained after filtering the xylan is subjected to rotary concentration and recovery Ethanol; then the lignin in it is separated by acid precipitation, and the residue after the separation of lignin is burned to recover alkali and heat ...

Embodiment 3

[0058] The present embodiment relates to a kind of preparation method of xylo-oligosaccharide, comprises the following steps:

[0059] 1) Wash and air-dry the bagasse, pulverize it with a pulverizer, and sieve it into 20 meshes to control its water content to be ≤5%. On a dry basis, put 10 kg of the bagasse in a pressure-resistant reaction kettle, add 100L of 50% (v / v) ethanol aqueous solution, add 0.5kg sodium hydroxide at the same time, heat to 100 ℃ after sealing, process 1h, cool down, obtain filtrate and filter residue after filtering;

[0060] 2) After the filtrate is concentrated by rotary evaporation, it is extracted with 3 times the volume of 95% (v / v) ethanol precipitation to obtain a xylan precipitate; the secondary filtrate obtained after filtering the xylan is subjected to rotary concentration and recovery Ethanol; then the lignin in it is separated by acid precipitation, and the residue after the separation of lignin is burned to recover alkali and heat energy. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com