High-proportion silicon negative electrode aqueous composite binder and application thereof

A composite binder and silicon negative electrode technology, which is applied in battery electrodes, structural parts, electrical components, etc., can solve the problems of negative electrode volume expansion and shrinkage, electrode powdering, etc., and achieve good adaptability, good tensile performance, and improved cycle time. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

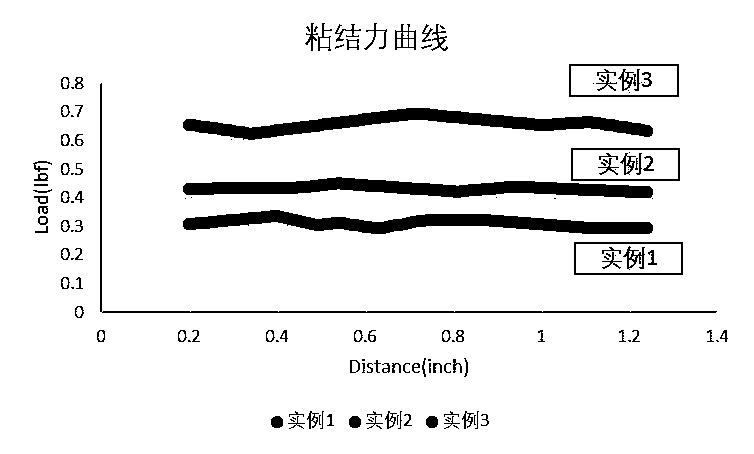

[0022] Application of PI-PAA-SBR composite binder in silicon negative electrode of lithium battery: SiOx (mixed carbon), conductive agent carbon black (Super-P) and composite binder with a mass ratio of 7.5:1:1.5 Made of negative electrode sheet. PI is configured as a 7.5% aqueous solution, PAA is configured as a 25% aqueous solution, and SBR is configured as a 5% aqueous solution. The three binders are mixed according to the mass ratio of 2:6:2) and the pH value of the mixed aqueous solution is adjusted using NaOH to (5-9). Put the negative electrode active material, conductive carbon, etc. into the binder aqueous solution in a certain order, and add water with a total mass fraction of 20%-40% to mix and homogenate. After the negative electrode sheet is rolled, the rolled negative electrode sheet is placed in a vacuum drying oven and heated in vacuum at 140° C. for 6 hours. The negative electrode sheet is completed. The peel strength test results are as follows figure 1 s...

example 2

[0024] Application of PI-PAA-SBR composite binder in silicon negative electrode of lithium battery: SiOx (mixed carbon), conductive agent carbon black (Super-P) and composite binder with a mass ratio of 7:1.5:1.5 Made of negative electrode sheet. PI is configured as a 5% aqueous solution, PAA is configured as a 30% aqueous solution, and SBR is configured as a 5% aqueous solution. The three binders are mixed according to a mass ratio of 3:6:1, and then NaOH is used to adjust the pH value of the mixed aqueous solution. to (5-9). Put the negative electrode active material, conductive carbon, etc. into the binder aqueous solution in a certain order, and add water with a total mass fraction of 20%-40% to mix and homogenate. After the negative electrode sheet is rolled, the rolled negative electrode sheet is placed in a vacuum drying oven and heated in vacuum at 180° C. for 4 hours. The negative electrode sheet is completed. The peel strength test results are as follows figure 1...

example 3

[0026] Application of PI-PAA-SBR composite binder in silicon negative electrode of lithium battery: SiOx (mixed carbon), conductive agent carbon black (Super-P) and composite binder with a mass ratio of 7.5:1.5:1 Made of negative electrode sheet. PI is configured as a 10% aqueous solution, PAA is configured as a 20% aqueous solution, and SBR is configured as a 5% aqueous solution. The three binders are mixed according to the mass ratio of 2.5:6:1.5, and then NaOH is used to adjust the pH value of the mixed aqueous solution. to (5-9). Put the negative electrode active material, conductive carbon, etc. into the binder aqueous solution in a certain order, and add water with a total mass fraction of 20%-40% to mix and homogenate. After the negative electrode sheet is rolled, the rolled negative electrode sheet is placed in a vacuum drying oven and heated in vacuum at 200° C. for 2 hours. The negative electrode sheet is completed. The peel strength test results are as follows f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com