Magnesium ion battery negative electrode material, magnesium ion battery and preparation method thereof

A magnesium ion battery and negative electrode material technology, applied in battery electrodes, electrolyte storage battery manufacturing, secondary batteries, etc., can solve the problems of complex preparation methods, high cost, hindering the deposition and dissolution of magnesium ions, and achieve low cost, lower potential, The effect of excellent electrochemical cycle stability and rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

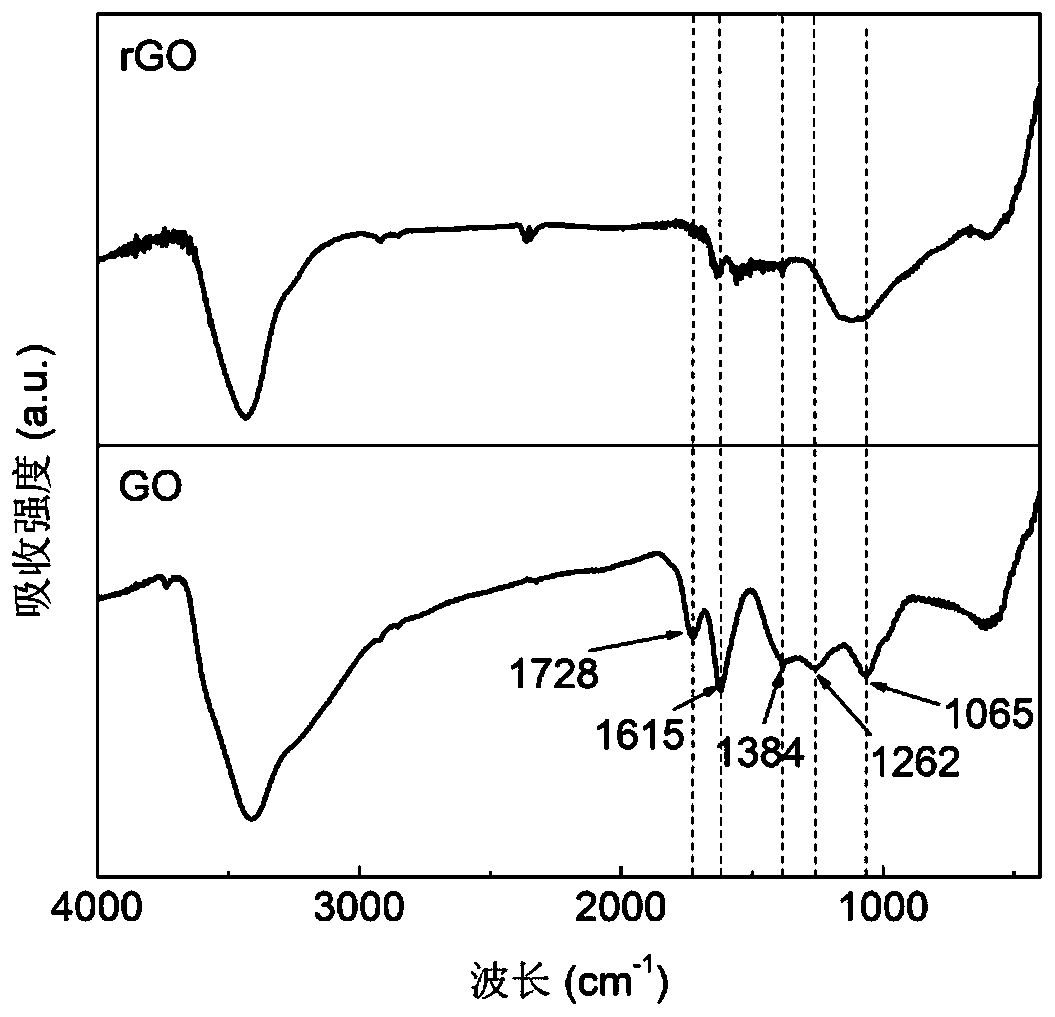

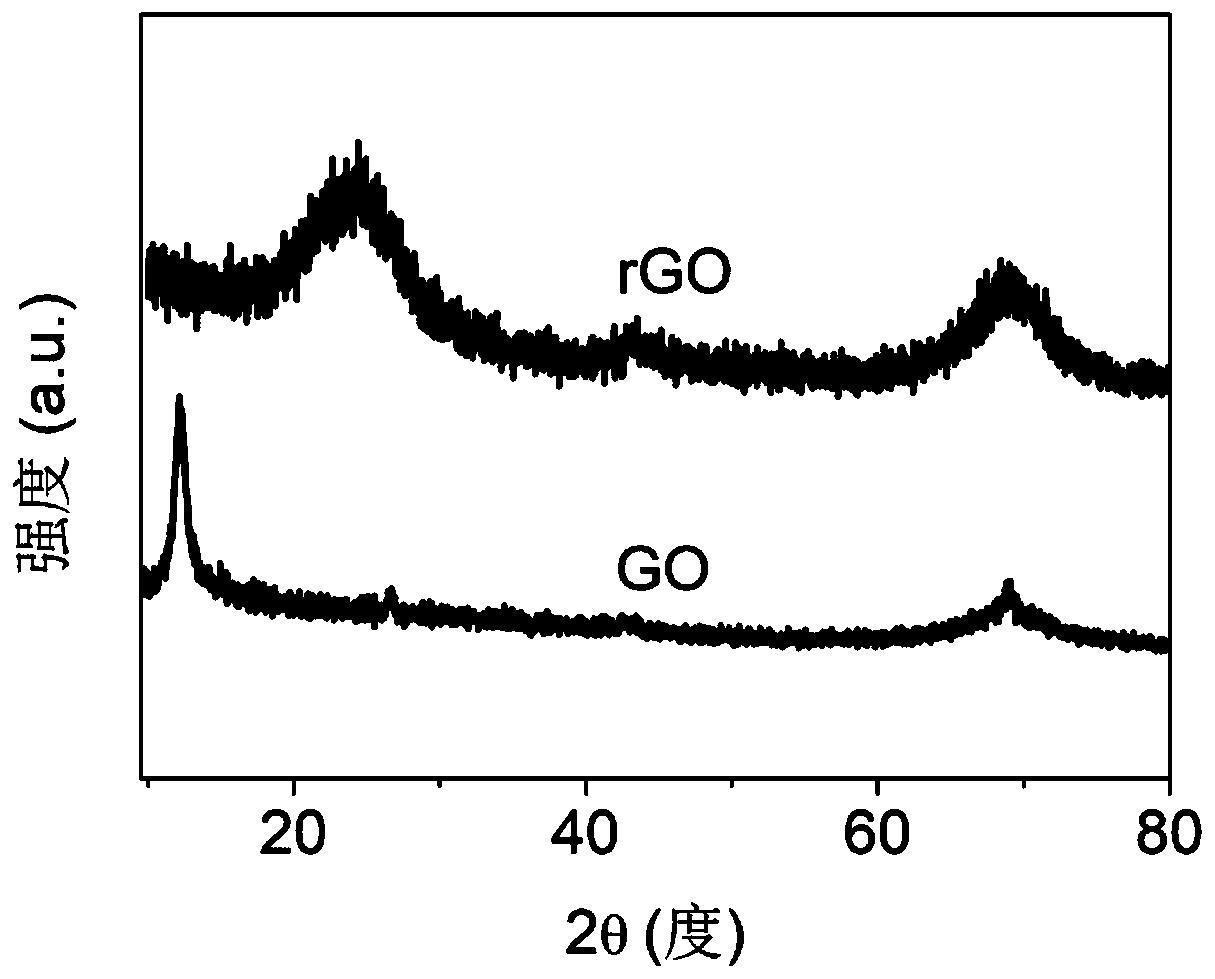

[0041] The embodiment of the present invention firstly provides a negative electrode material for a magnesium ion battery, the negative electrode material for a magnesium ion battery is a defect-rich reduced graphene oxide obtained by reducing graphene oxide with a reducing agent hydrazine hydrate; Defect-containing refers to the intensity ratio (I D / I G ) is in the range of 1 to 1.5. Its preparation method comprises the following steps:

[0042] S11, adopting improved Hummers method to prepare graphene oxide;

[0043] S12. Prepare the prepared graphene oxide into a solution with a concentration of 0.2 mg / mL-0.6 mg / mL, add hydrazine hydrate, stir and mix, and then reduce at a temperature of 80°C-100°C for 20min-1h to prepare reduced graphite oxide ene, and the reduced graphene oxide is used as a negative electrode material for a magnesium ion battery.

[0044] In step S12, the mass ratio of the graphene oxide to the hydrazine hydrate is preferably 10:8˜10:10.

[0045] An...

Embodiment 1

[0054] Embodiment 1: the preparation of negative electrode material and negative electrode

[0055] (1) Firstly, graphene oxide (GO) was prepared by the modified Hummers method.

[0056] (2) Then, the prepared graphene oxide (GO) was formulated into a 0.5 mg / mL solution, added with hydrazine hydrate, stirred and mixed, and then reduced at high temperature.

[0057] (3) After the reduction reaction is completed, it is filtered and washed with deionized water until neutral, and dried in an oven to obtain highly active and defect-rich reduced graphene oxide (rGO).

[0058] (4) Dissolving the reduced graphene oxide in absolute ethanol to obtain a dispersion, adding the dispersion to the current collector and drying it to prepare a negative electrode.

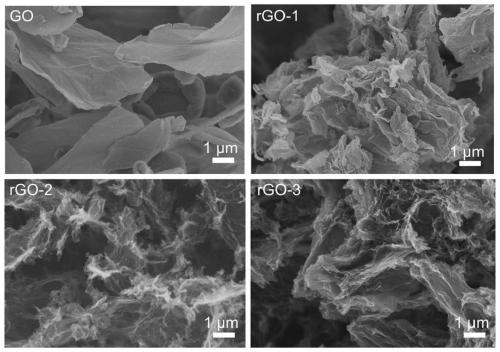

[0059] In this example, three kinds of reduced graphene oxide samples rGO-1, rGO-2 and rGO-3 were prepared by adjusting the mass ratio of hydrazine hydrate and graphene oxide added in the above step (2) and the reduction reaction t...

Embodiment 2

[0068] Embodiment 2: the preparation of electrolyte

[0069] (1), 19mg of magnesium chloride (MgCl 2 ) and 78mg yttrium trichloride (YCl 3 ) into 0.8 mL of N-butylpyridine bistrifluoromethanesulfonic acid ionic liquid, heated and stirred at 160° C. for 24 h, and then cooled to room temperature to form the first solution.

[0070] (2), add 1.5mL diethylene glycol dimethyl ether to coordinate with magnesium ions in the first solution, prepare and obtain based on MgCl 2 -YCl 3 The electrolyte of the solution, hereinafter denoted as MgCl 2 -YCl 3 electrolyte.

[0071] As a comparison, this embodiment also prepared electrolytes commonly used in other two magnesium-ion batteries:

[0072] The first one: 0.533g aluminum trichloride (AlCl 3 ) was slowly added into 6mL of tetrahydrofuran (THF), stirred until dissolved, then 4mL of benzyl magnesium chloride solution (2M PhMgCl in THF) was slowly added dropwise to the above solution, and stirred at room temperature for 24h to prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com