Preparation method of copolymerized organic silicon resin microspheres

A technology of resin microspheres and silicones, applied in the chemical industry, can solve the problems of incomplete spherical structure, restricting the application of light diffusing agents, affecting the effect of light diffusion, etc., and achieve the effect of precise shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

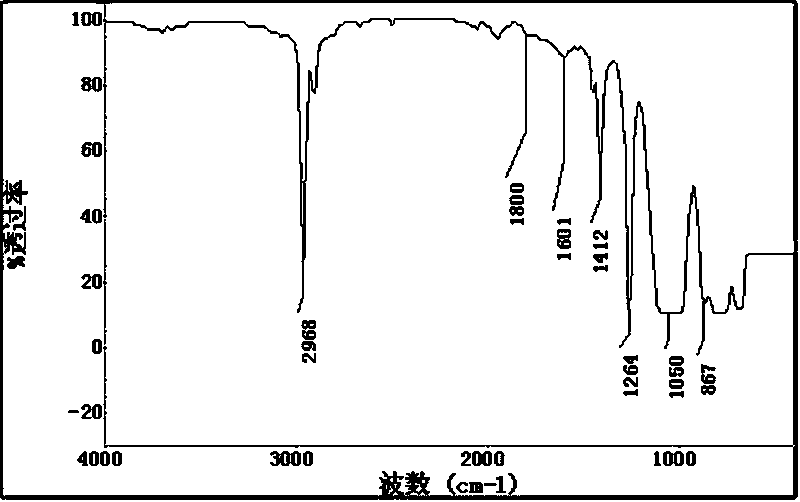

Image

Examples

Embodiment 1

[0027] A preparation method of copolymerized silicone resin microspheres, the operation steps are:

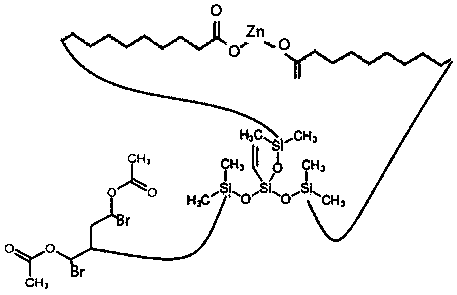

[0028] Add 40g of vinyltris(dimethylsiloxane)silane into the reactor, stir and mix evenly, then add 8g of 1,1,3,3-tetramethyldisiloxane, then raise the temperature to 40°C , stirred and mixed for 60min, then added 400g of purified water, 0.1g of trichlorovinyl platinum (II) potassium and 0.5g of high-efficiency microemulsifier, 0.5g of 1,4-dibromoacetoxy-2-butyl Alkene and 0.03g of zinc undecylenate were stirred and mixed at high speed for 20 minutes, then ultrasonically dispersed for 10 minutes to form a microemulsion, then heated to 40°C, and reacted for 120 minutes. After the reaction was completed, 30g of ammonia water was added, and the temperature was raised to 65°C, and the reaction was continued for 30 minutes. After the reaction is completed, centrifugal sedimentation, filtration and drying can obtain the above-mentioned a kind of copolymerized silicone resin microsphe...

Embodiment 2

[0036] A preparation method of copolymerized silicone resin microspheres, the operation steps are:

[0037] Add 45g of vinyltris(dimethylsiloxane)silane into the reactor, stir and mix evenly, add 11g of 1,1,3,3-tetramethyldisiloxane, and then raise the temperature to 50°C , stirred and mixed for 67min, then added 455g of purified water, 0.2g of trichlorovinyl platinum (II) potassium and 1g of high-efficiency microemulsifier, 1g of 1,4-dibromoacetoxy-2-butene and 0.09g of zinc undecylenate, mixed at high speed for 25 minutes, then ultrasonically dispersed for 18 minutes to form a microemulsion, then heated to 50°C, and reacted for 180 minutes. After the reaction was completed, 50g of ammonia water was added, heated to 69°C, and continued to react for 40 minutes; completed After the reaction, the copolymerized silicone resin microspheres can be obtained by centrifugal sedimentation, filtration and drying.

[0038] Described high-efficiency microemulsifier is processed and prepare...

Embodiment 3

[0046] A preparation method of copolymerized silicone resin microspheres, the operation steps are:

[0047] Add 68g of vinyltris(dimethylsiloxane)silane into the reactor, stir and mix evenly, then add 19g of 1,1,3,3-tetramethyldisiloxane, then raise the temperature to 60°C , stirred and mixed for 90min, then added 700g of purified water, 0.5g of trichlorovinyl platinum (II) potassium and 3g of high-efficiency microemulsifier, 2.3g of 1,4-dibromoacetoxy-2-butene Mix with 0.6g of zinc undecylenate, stir and mix at high speed for 30min, then ultrasonically disperse for 30min to form a microemulsion, then heat up to 60°C, react for 240min, add 70g of ammonia water after the reaction is completed, heat up to 85°C, and continue to react for 60min; After the reaction is completed, the copolymerized silicone resin microspheres can be obtained by centrifuging, filtering and drying.

[0048] Described high-efficiency microemulsifier is processed and prepared according to the following ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com